Viscose waste residue treatment system

A treatment system and waste residue technology, which is applied to the removal of solid waste, chemical instruments and methods, transportation and packaging, etc., can solve the problems of large environmental pollution, reduce energy consumption, ensure quality, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

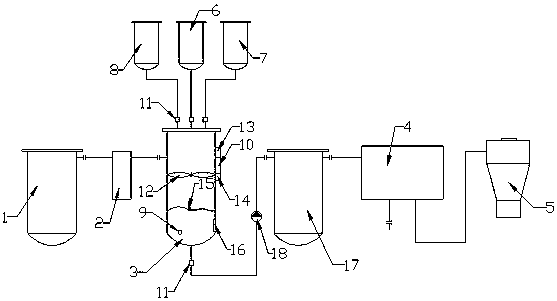

[0022] This embodiment, as the best embodiment of the present invention, discloses a viscose waste treatment system, the specific structure is as follows figure 1 As shown, it includes a waste rubber storage tank 1, and the outlet end of the waste rubber storage tank 1 is connected with a butterfly separator 2, a waste residue reaction tank 3, a filter press 4 and an incinerator 5 through pipelines; 3 is also connected with a concentrated sulfuric acid storage tank 6, a coagulant aid storage tank 7 and a flocculant storage tank 8 through pipelines; the waste rubber reaction tank 3 is provided with a pH sensor 9, and the waste rubber reaction tank 3 is provided with a controller 10 , the input end of the controller 10 is connected with the pH sensor 9, the outlet end of the waste rubber reaction tank 3 is provided with an electromagnetic flow valve 11, and the electromagnetic flow valve 11 is connected with the controller 10; the concentrated sulfuric acid storage tank 6 1. Ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com