Power distribution cabinet cooling method

A technology for power distribution cabinets and cabinets, applied in the field of power equipment manufacturing, can solve problems such as single method, damage to equipment, and failure to prevent dust from entering the interior of the cabinet, and achieve the effects of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Further detailed explanation through specific implementation mode below:

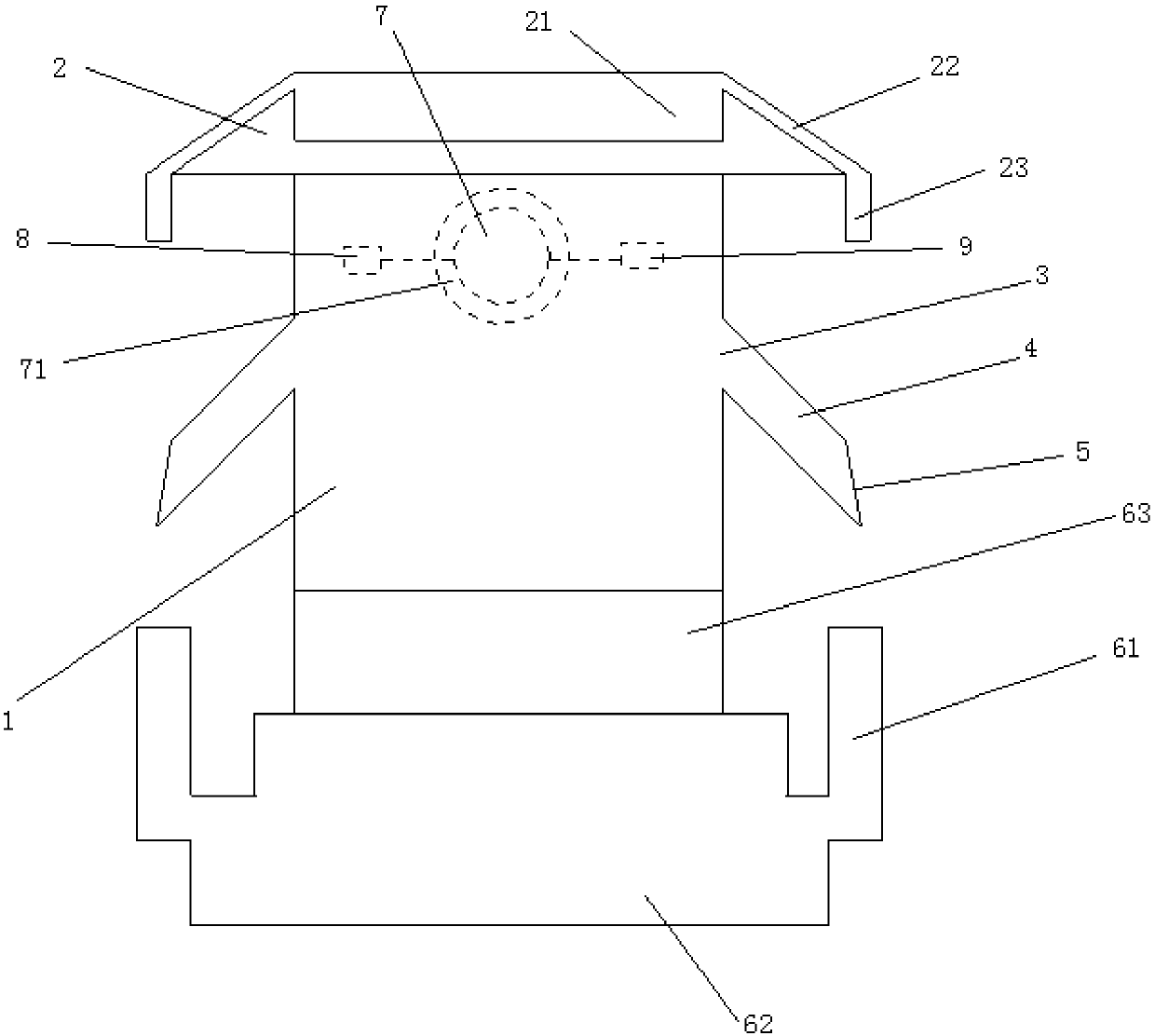

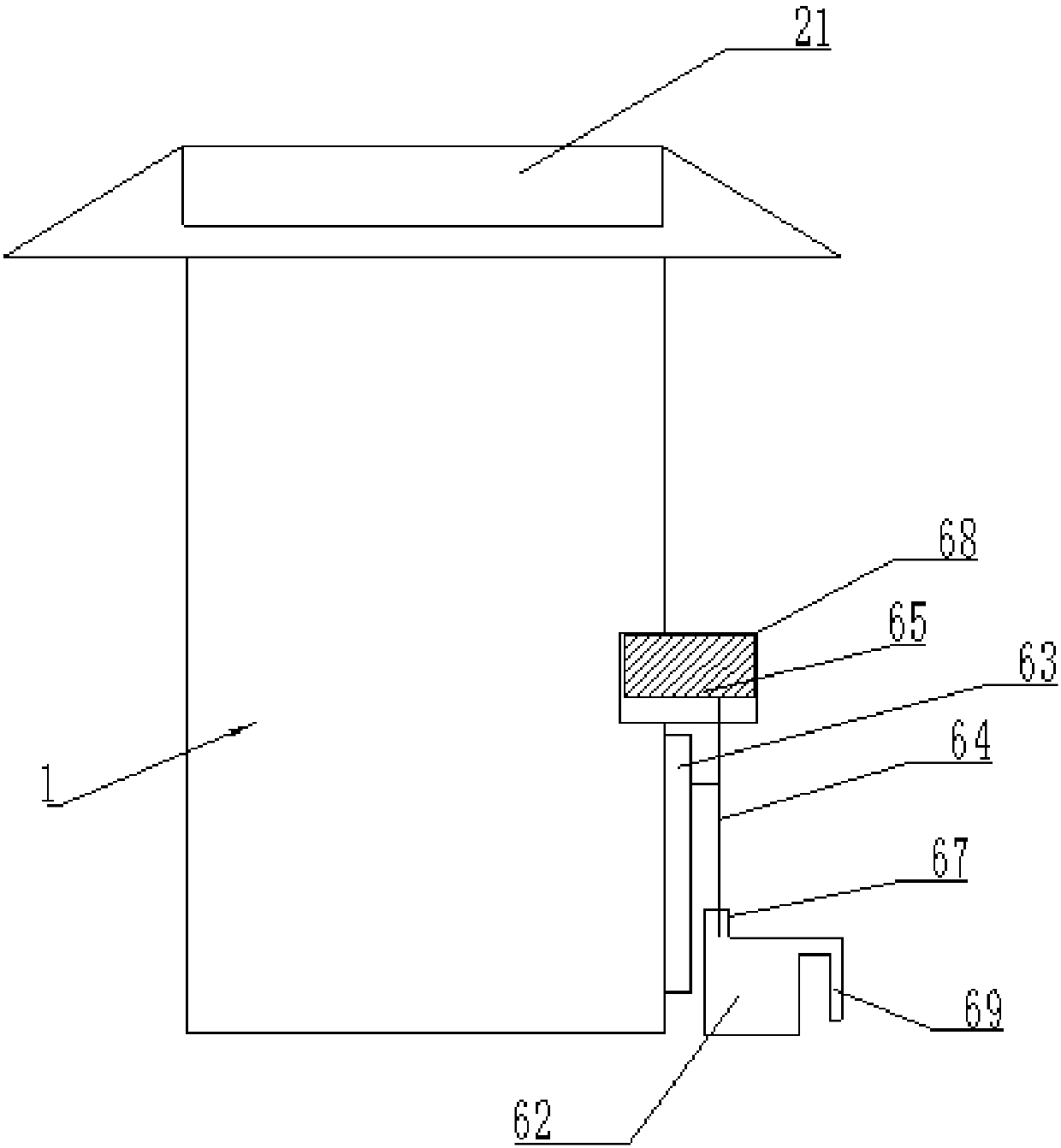

[0023] The reference signs in the drawings of the description include: cabinet 1, cleaning device 2, water collection tank 21, drainage pipe 22, drainage water pipe 23, vent 3, vent pipe 4, dust removal net 5, water receiving pipe 61, water storage tank 62, sponge layer 63, cotton rope 64, inflatable air bag 65, cotton rope hole 67, mesh cage 68, drainage pipe 69, fan 7, dustproof cover 71, temperature sensor 8, microcontroller 9.

[0024] Such as figure 1 As shown, a power distribution cabinet for cooling and dust removal includes a cabinet body 1 and a water storage device 2, a cleaning device is fixedly installed above the cabinet body, and a water collection tank 21 is opened in the center of the cleaning device 2. When rainy days come, Rainwater can be stored in the sump 21, and when the temperature rises, the water above the cabinet 1 can properly cool the top of the cabinet, and drainage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com