A low-speed impact test fixture with continuously adjustable impact angle

A technology of low-speed impact and test fixture, which is applied in the direction of impact test, machine/structural component test, measuring device, etc. It can solve the problems of increased test cost and impossibility of plate impact test, etc., and achieves simple structure, small footprint, and easy The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

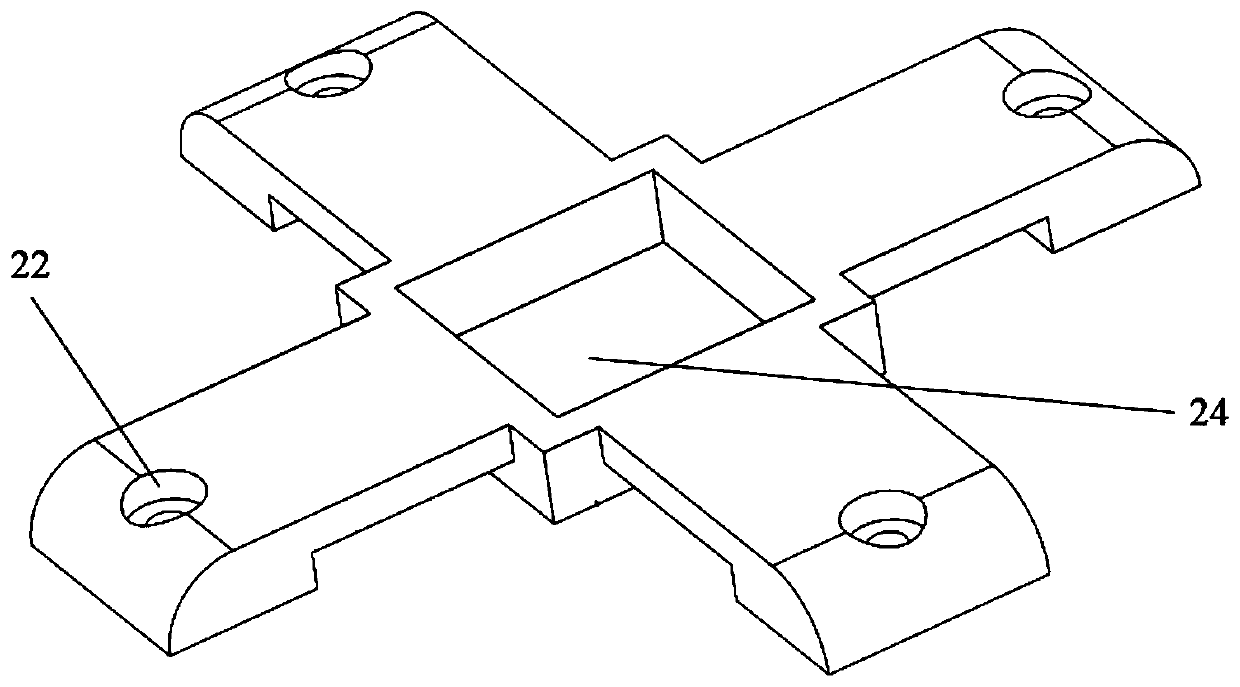

[0012] The low-speed impact test jig with continuously adjustable impact angle provided by the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings:

[0013] Such as figure 1 As shown, the low-speed impact test jig provided by the present invention includes a jig upper splint 2, a plane corner angle disc 4, a test piece fixing plate 5, a top plate 6, a pointer 7, a centering triangle block 8, and a rotating shaft 9. , elevation angle plate 10, baffle plate 11, square head support column 12, connecting shaft 13, round head support column 14, upper fixing nut 16, lower fixing nut 17, supporting base plate 18, laser transmitter 19, supporting column 20, fixing Plate 21; wherein the fixed plate 21 is arranged horizontally; the upper and lower ends of the four supporting columns 20 are respectively connected to the bottom surface of the supporting base plate 18 and the four corners of the surface of the fixing plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com