a liquid reservoir

A liquid receiver and vessel body technology, applied in the field of refrigeration, can solve the problems of refrigerant leakage, difficult manufacturing, and low production efficiency, and achieve the effects of regular appearance, improved appearance quality, improved sealing performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to enable those skilled in the art to better understand the solution of the present invention, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

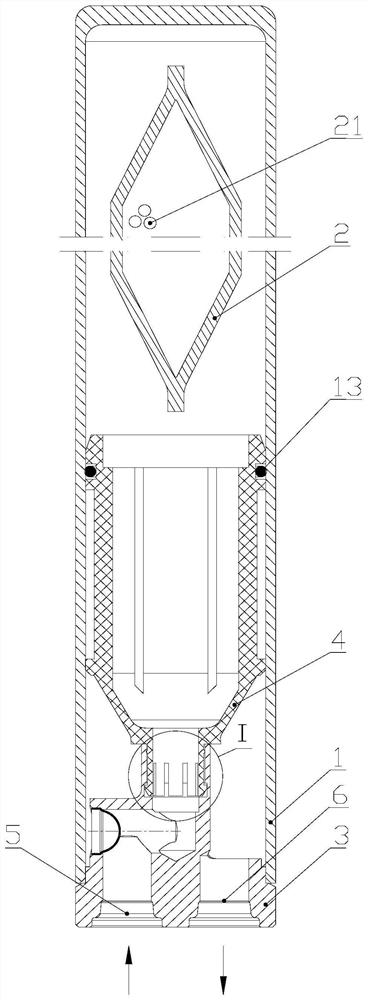

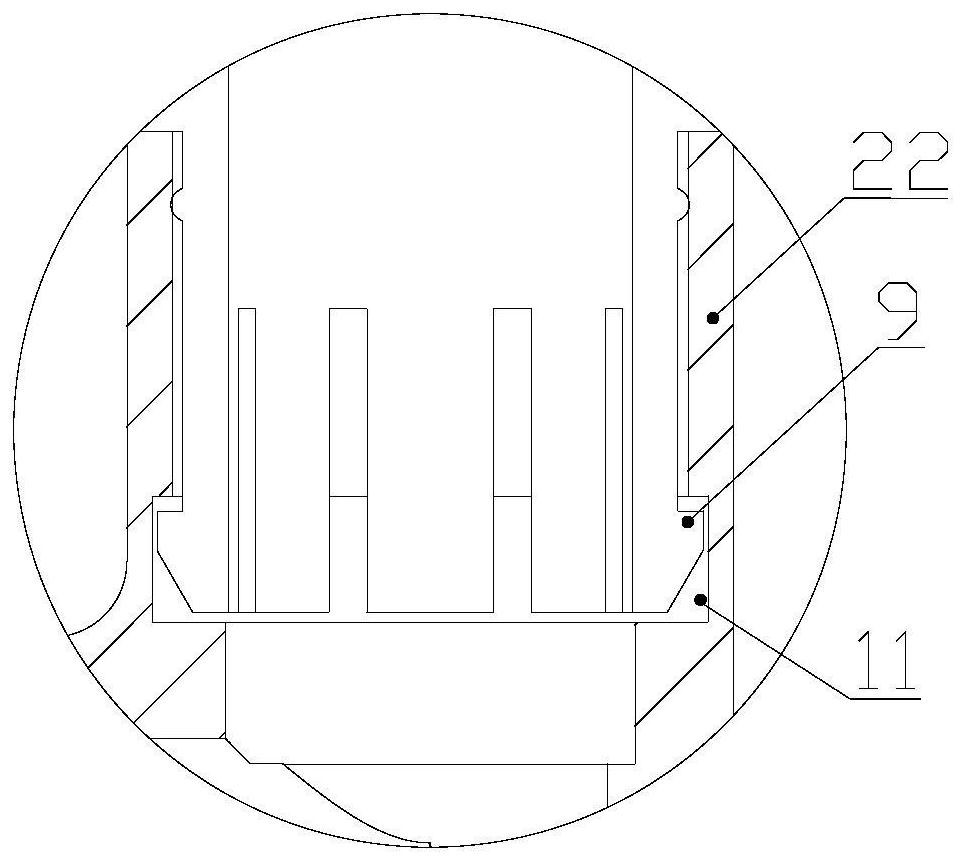

[0052] Please refer to figure 2 , image 3 , figure 2 It is a schematic structural diagram of a liquid reservoir disclosed in an embodiment of the present invention; image 3 for figure 2 Partial enlarged view of the middle I site.

[0053] The liquid receiver in this embodiment is a body type liquid receiver, which is used for storing refrigerant, filtering impurities and absorbing water in the automobile air-conditioning system.

[0054] As shown in the figure, the liquid reservoir includes a body 1 , a drying bag 2 inside the body 1 , a cap 3 at one end of the body 1 , and a filter 4 inside the body 1 .

[0055] The body 1 has a cylindrical structure, and a cavity is formed inside it, and one end is closed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com