Ecological thermal-insulation waterproof plate

A waterproof board and ecological technology, applied in thermal insulation, building thermal insulation materials, applications, etc., can solve the problems of affecting indoor comfort, increasing operating costs, poor thermal insulation effect, etc., achieve good waterproof thermal insulation effect, easy installation and disassembly, Good effect of absorbing nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

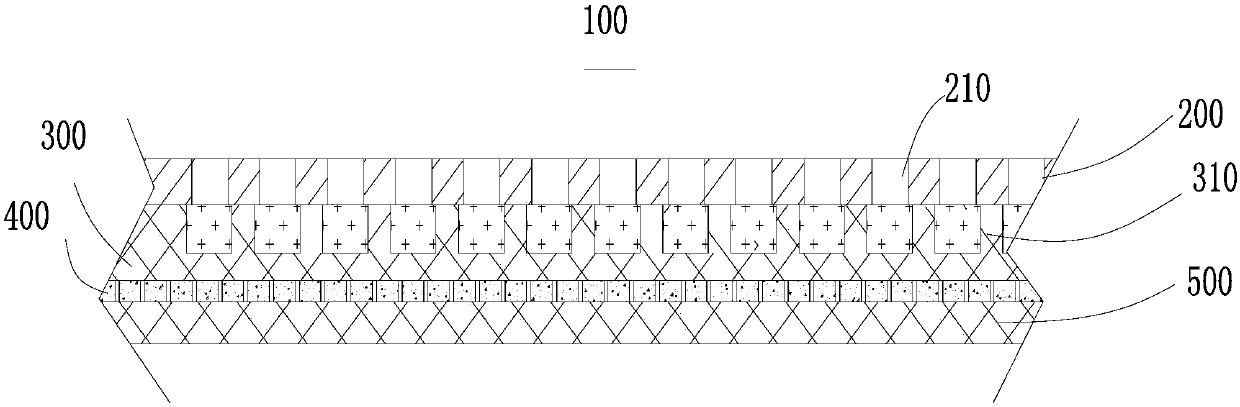

[0023] The ecological heat preservation and waterproof board 100 sequentially includes a first aluminum-plastic board 200, a foamed resin 300, a polytetrafluoroethylene microporous membrane 400 and a second aluminum-plastic board 500 (structure such as figure 1 shown); the first aluminum-plastic panel 200 is provided with a plurality of through-holes 210 with a diameter of 1 cm, the opening ratio is 10%, the thickness of the first aluminum-plastic panel 200 and the second aluminum-plastic panel 500 is 0.5 cm, and the foaming One end of the resin 300 close to the first aluminum-plastic plate 200 is provided with a plurality of filling grooves 310, and each filling groove 310 is filled with Sagegrass seeds and fertilizer wrapped in a starch-grafted phenolic resin film. The first aluminum-plastic plate 200 , the foamed resin 300 , the polytetrafluoroethylene microporous membrane 400 and the second aluminum-plastic plate 500 are connected by rivets.

[0024]The starch-grafted phen...

Embodiment 2

[0027] The ecological heat preservation and waterproof board 100 sequentially includes a first aluminum-plastic board 200, a foamed resin 300, a polytetrafluoroethylene microporous membrane 400 and a second aluminum-plastic board 500 (structure such as figure 2 shown); the first aluminum-plastic plate 200 is provided with a plurality of through-holes 210 with a diameter of 1.5 cm, and the opening rate is 15%, and the thickness of the first aluminum-plastic plate 200 and the second aluminum-plastic plate 500 is 0.5 cm, and the One end of the foam resin 300 close to the first aluminum-plastic plate 200 is provided with a plurality of filling grooves 310, and each filling groove 310 is filled with zoysia seeds and fertilizers wrapped in a starch-grafted phenolic resin film. The first aluminum-plastic The plate 200, the foamed resin 300, the polytetrafluoroethylene microporous membrane 400 and the second aluminum-plastic plate 500 are connected by rivets.

[0028] The starch-graf...

Embodiment 3

[0031] The ecological heat preservation and waterproof board 100 sequentially includes a first aluminum-plastic board 200, a foamed resin 300, a polytetrafluoroethylene microporous membrane 400 and a second aluminum-plastic board 500 (structure such as image 3 shown); the first aluminum-plastic panel 200 is provided with a plurality of through-holes 210 with a diameter of 1.2cm, and the opening rate is 12%, and the thickness of the first aluminum-plastic panel 200 and the second aluminum-plastic panel 500 is 0.5cm, and the One end of the foam resin 300 close to the first aluminum-plastic plate 200 is provided with a plurality of filling grooves 310, and each filling groove 310 is filled with Sage grass seeds, Zoysia seeds, and money wrapped in starch-grafted phenolic resin film. Grass seeds and fertilizers, the first aluminum-plastic plate 200, the foamed resin 300, the polytetrafluoroethylene microporous membrane 400 and the second aluminum-plastic plate 500 are connected by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com