Seaweed fertilizer with stress resistance function

A reverse action and fertilizer technology, applied in the field of seaweed fertilizer, can solve the problems of small increase in crop yield, damage to soil acid-base balance, and limited organic fertilizer resources, so as to increase soil biological vitality, increase water and gas retention capacity, and utilize high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

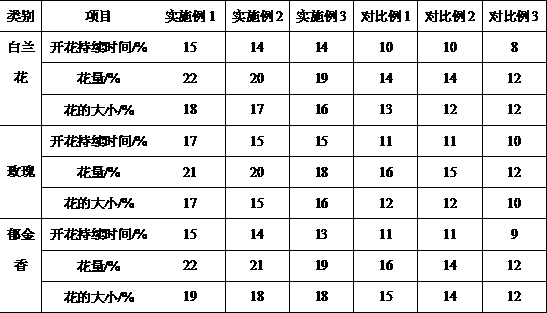

Examples

Embodiment 1

[0024] A seaweed fertilizer with anti-adversity effect is prepared from the following raw materials in parts by weight: 130 parts of seaweed residue, 30 parts of cassava residue, 13 parts of vermicompost, 0.4 part of fermentation bacteria agent, 0.2 part of fermentation accelerator, nitrogen and phosphorus 70 parts of potassium fertilizer, 30 parts of attapulgite, and 3 parts of dispersed aggregate.

[0025] The fermentation agent is prepared from Bacillus subtilis, Enterobacter ludwig and Thiobacillus ferrooxidans according to the volume ratio of 1:0.9:0.7.

[0026] The fermentation accelerator is prepared from chitosan oligosaccharide, dipropylene glycol and gluconic acid in a weight ratio of 1:0.3:1.

[0027] The NPK fertilizer is prepared from potassium chloride, urea, potassium sulfate, ammonium nitrate, diammonium phosphate and superphosphate in a weight ratio of 1:1.2:0.7:0.7:0.4:0.3.

[0028] The dispersed aggregate is prepared from ethylene glycol monobutyl ether and...

Embodiment 2

[0037] A seaweed fertilizer with anti-adversity effect is prepared from the following raw materials in parts by weight: 150 parts of seaweed dregs, 20 parts of cassava dregs, 10 parts of vermicompost, 0.5 parts of fermentation bacteria agent, 0.2 parts of fermentation accelerator, nitrogen and phosphorus 50 parts of potassium fertilizer, 40 parts of attapulgite, and 2 parts of dispersed aggregate.

[0038] The fermentation agent is prepared from Bacillus subtilis, Enterobacter ludwig and Thiobacillus ferrooxidans according to the volume ratio of 1:0.8:0.9.

[0039] The fermentation accelerator is prepared from chitosan oligosaccharide, dipropylene glycol and gluconic acid in a weight ratio of 1:0.2:1.2.

[0040] The NPK fertilizer is prepared from potassium chloride, urea, potassium sulfate, ammonium nitrate, diammonium phosphate and superphosphate in a weight ratio of 1:0.8:0.6:0.9:0.3:0.4.

[0041] The dispersed aggregate is prepared from ethylene glycol monobutyl ether and...

Embodiment 3

[0044] A seaweed fertilizer with anti-adversity effect is prepared from the following raw materials in parts by weight: 100 parts of seaweed dregs, 40 parts of cassava dregs, 15 parts of vermicompost, 0.3 parts of fermentation bacteria agent, 0.2 parts of fermentation accelerator, nitrogen and phosphorus 90 parts of potassium fertilizer, 20 parts of attapulgite, and 4 parts of dispersed aggregate.

[0045] The fermentation agent is prepared from Bacillus subtilis, Enterobacter ludwig and Thiobacillus ferrooxidans at a volume ratio of 1:1:0.5.

[0046] The fermentation accelerator is prepared from chitosan oligosaccharide, dipropylene glycol and gluconic acid in a weight ratio of 1:0.4:0.8.

[0047] The NPK fertilizer is prepared from potassium chloride, urea, potassium sulfate, ammonium nitrate, diammonium phosphate and superphosphate in a weight ratio of 1:1.5:0.8:0.5:0.5:0.2.

[0048] The dispersed aggregate is prepared from ethylene glycol monobutyl ether and polyethylene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com