Two-driven-by-one overturning and conveying device for mask blank making machine

A technology of conveying device and mask is applied in the field of one-for-two-turning conveying device for mask punching machine, which can solve the problems of inaccurate film feeding, inconsistent production rhythm, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

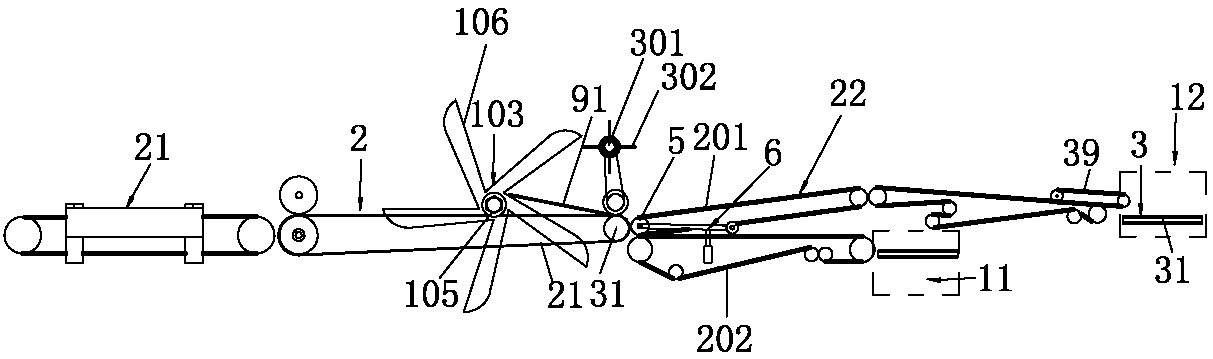

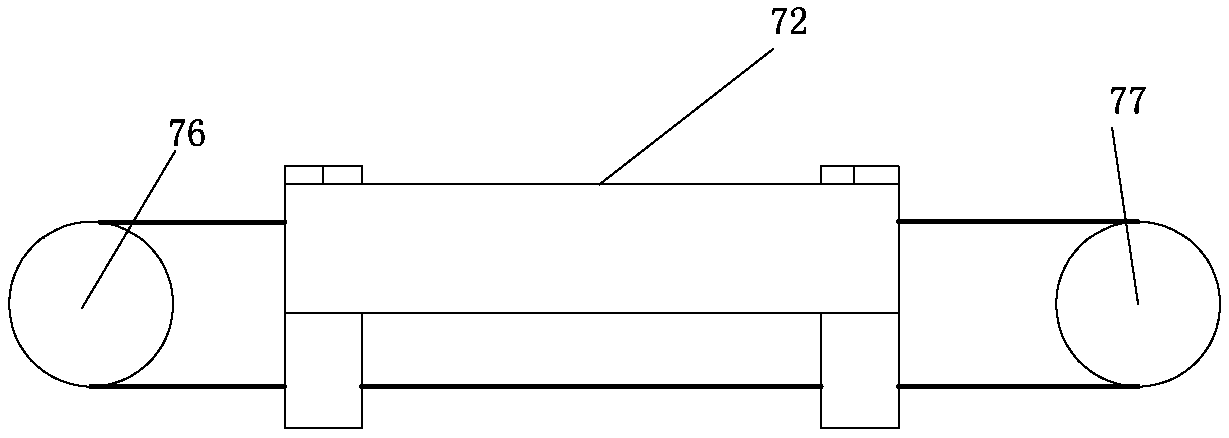

[0023] Specific implementation mode one: please refer to Figure 1-8 , a mask punching machine with one dragging and two flipping conveying devices, the conveying device includes a feeding conveying mechanism 21 connected to the mask punching machine 1 and a dual-channel conveying mechanism 22 connected to the mask ear strap welding machines 11 and 12 , between the feeding conveying mechanism 21 and the dual-channel conveying mechanism 22, there is a turning conveying mechanism 10, the turning conveying mechanism 10 includes a main conveying roller 101, an auxiliary conveying roller 102, and the main conveying roller 101 and the auxiliary conveying The transmission roller system that roller 102 constitutes is wound with main conveyer belt 9, and the feeding end of described main conveyer belt 9 is connected with the discharge end of feeding conveying mechanism 21, and the discharge end of described main conveyer belt 9 is connected with double The channel conveying mechanism 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com