Multistage hybrid powertrain for a motor vehicle

A technology of hybrid power and power train, applied in the direction of arrangement of multiple different prime movers of hybrid vehicles, motor vehicles, general power plants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

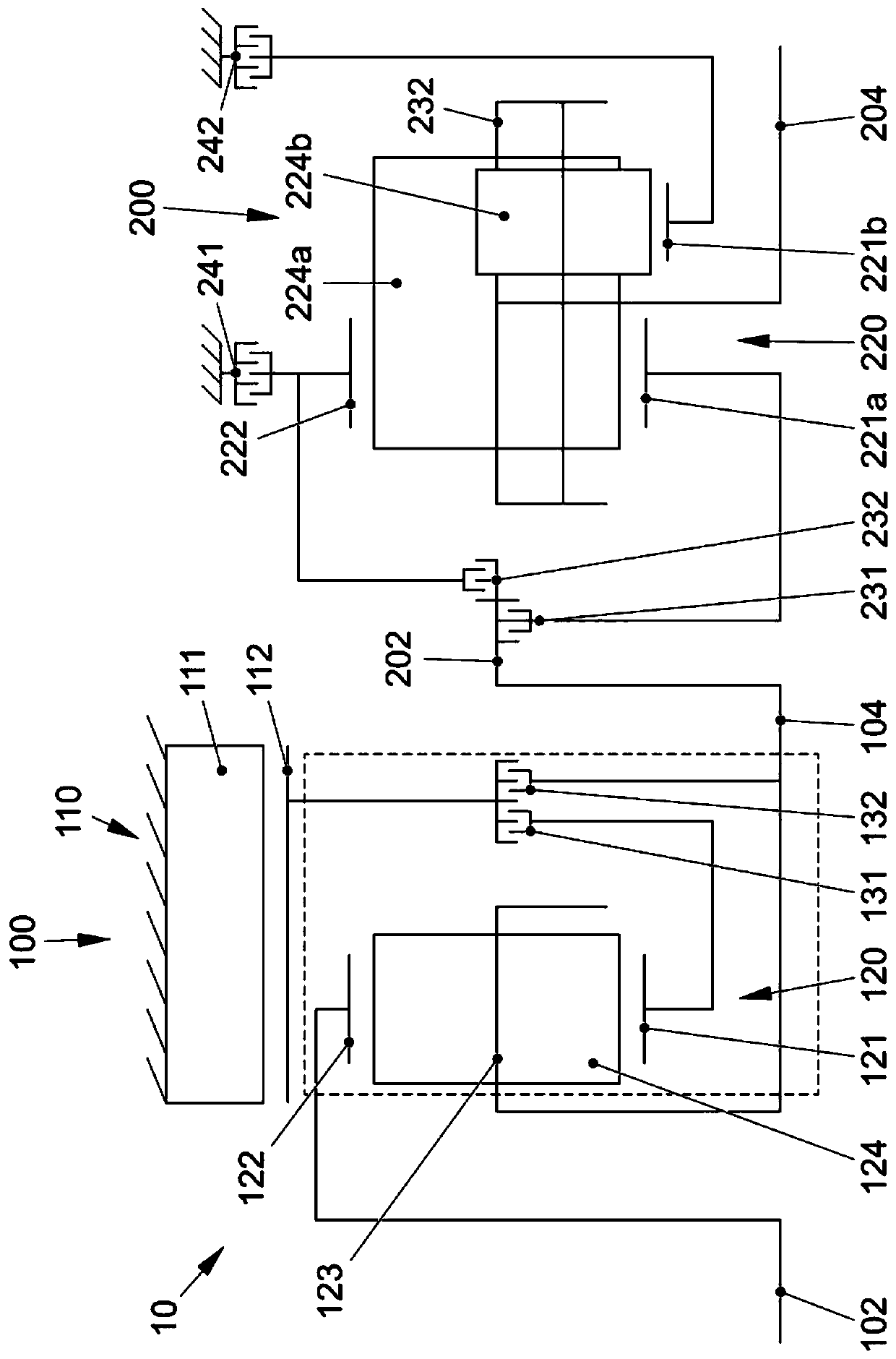

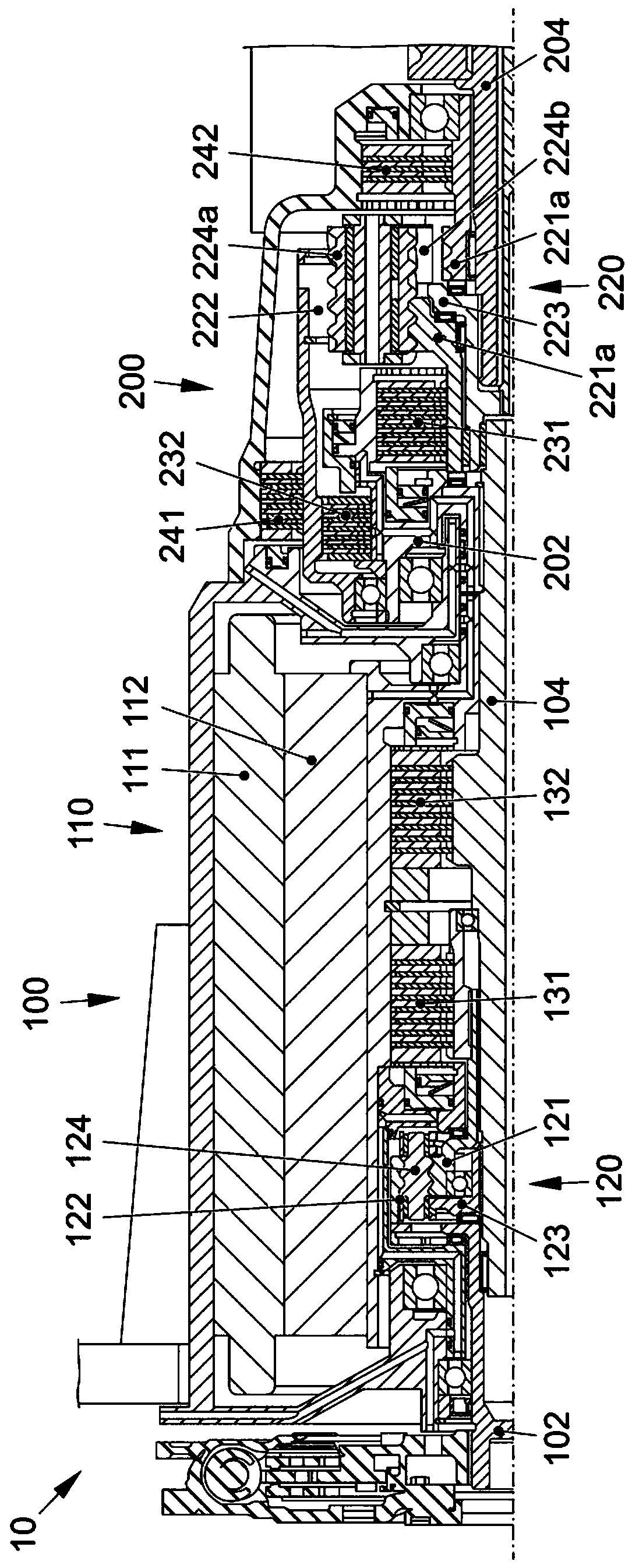

[0036] figure 1 示出按照本发明的传动系10的实施方式的拓扑示意图。传动系10包括输入级100和次级200。

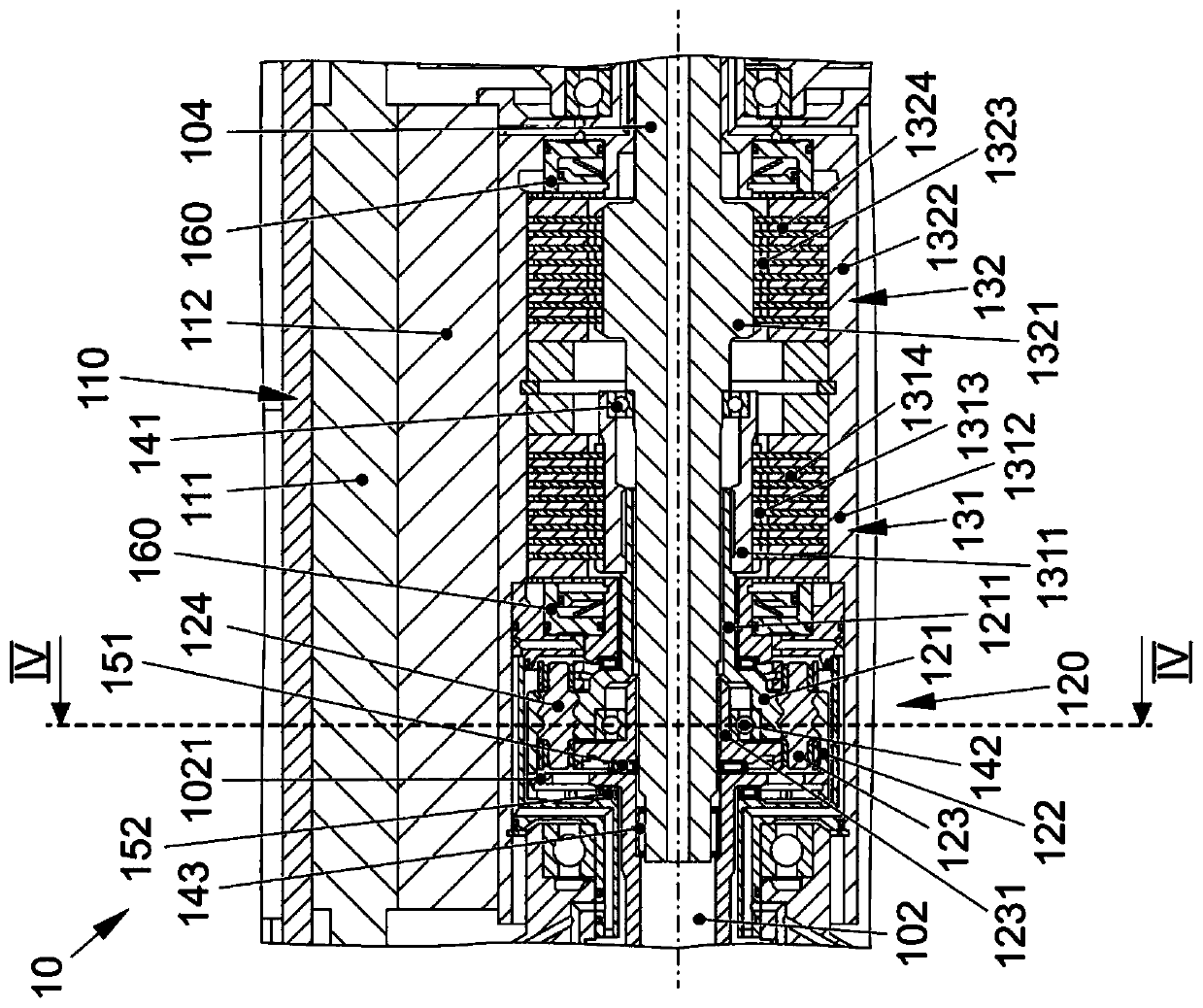

[0037]The input stage 100 comprises a stage input shaft 102 on the input side, a stage output shaft 104 on the output side, an electric motor 110 with a stator 111 fixed to the housing and a rotatably mounted , the inner rotor 112, the planetary gear set is designed in the embodiment shown as a simple planetary gear set, which has a sun gear 121, a ring gear 122 and a planet carrier 123, on which the planetary gear is rotatably mounted A set of planetary gears 124 meshes with the sun gear 121 on the one hand and with the ring gear 122 on the other hand.

[0038] The stage input shaft 102 is fixedly connected with the ring gear 122 . The stage output shaft 104 is fixedly connected to the planet carrier 123 . The rotor 112 of the electric machine 110 is coupled to the sun gear 121 via a first input stage clutch 131 . Furthermore, the rotor is coupled to the stage output shaft 104 via the second input stage clutc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com