Core pulling process for light weight wallboard

A lightweight wallboard and process technology, which is applied in the directions of ceramic forming cores, ceramic forming mandrels, etc., can solve the problems of low production efficiency and troublesome operation process, and achieve the effect of simplifying the structure, wide application range and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

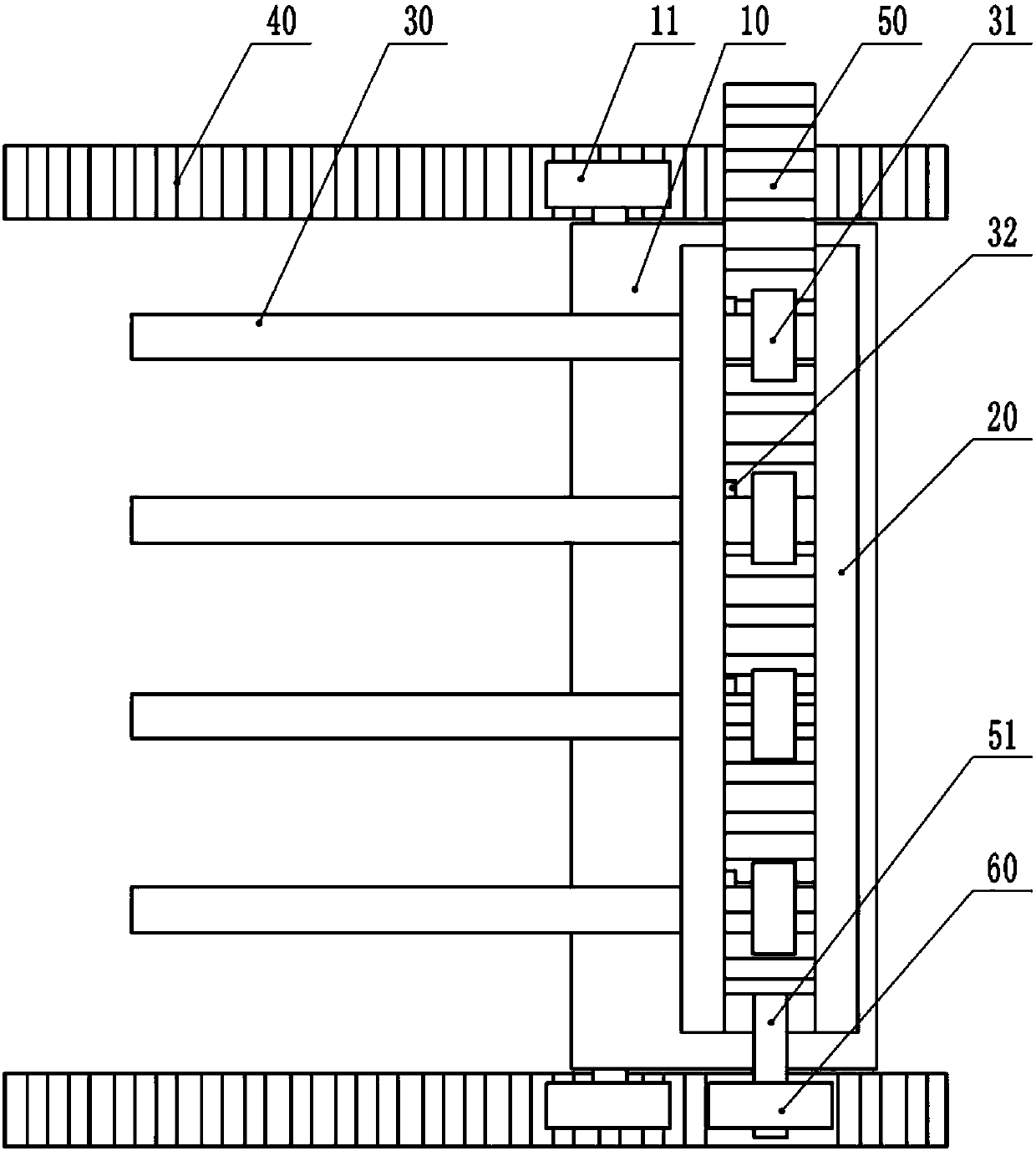

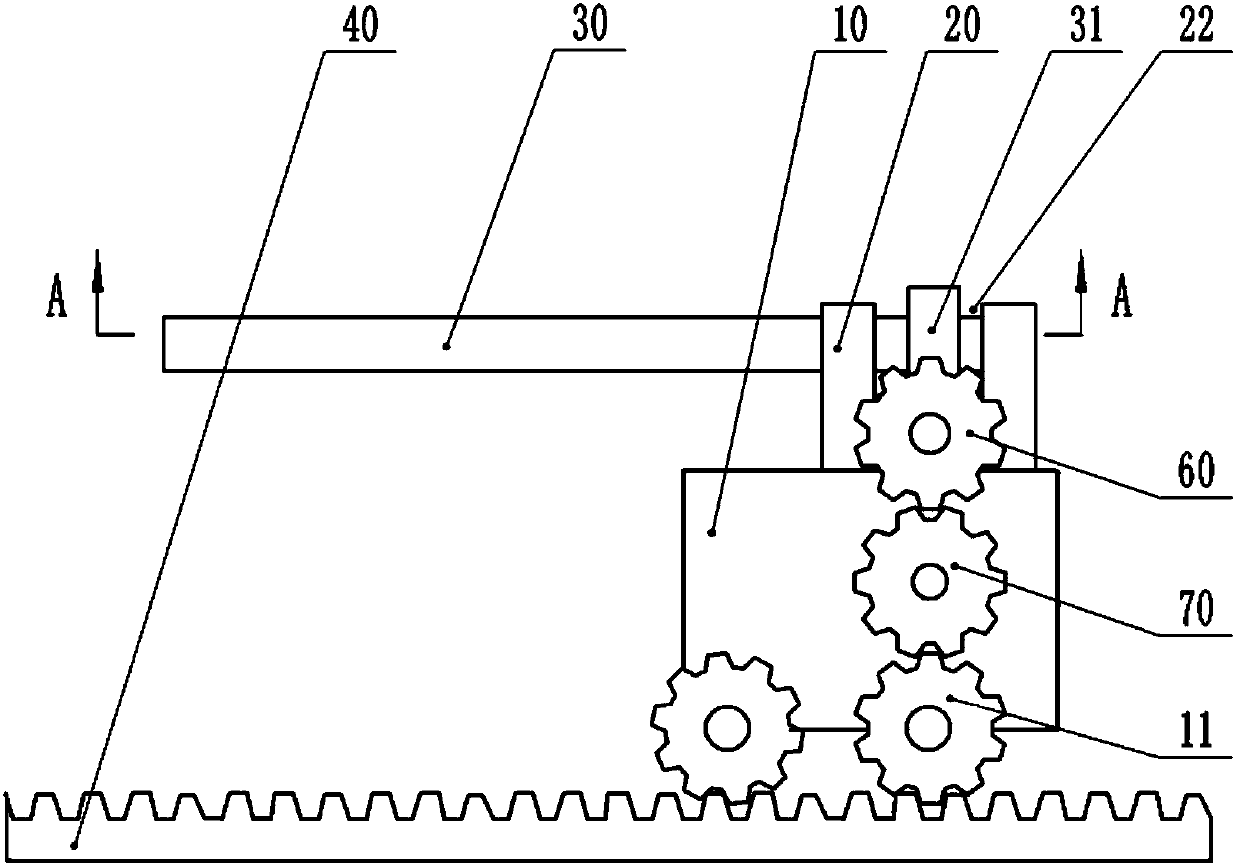

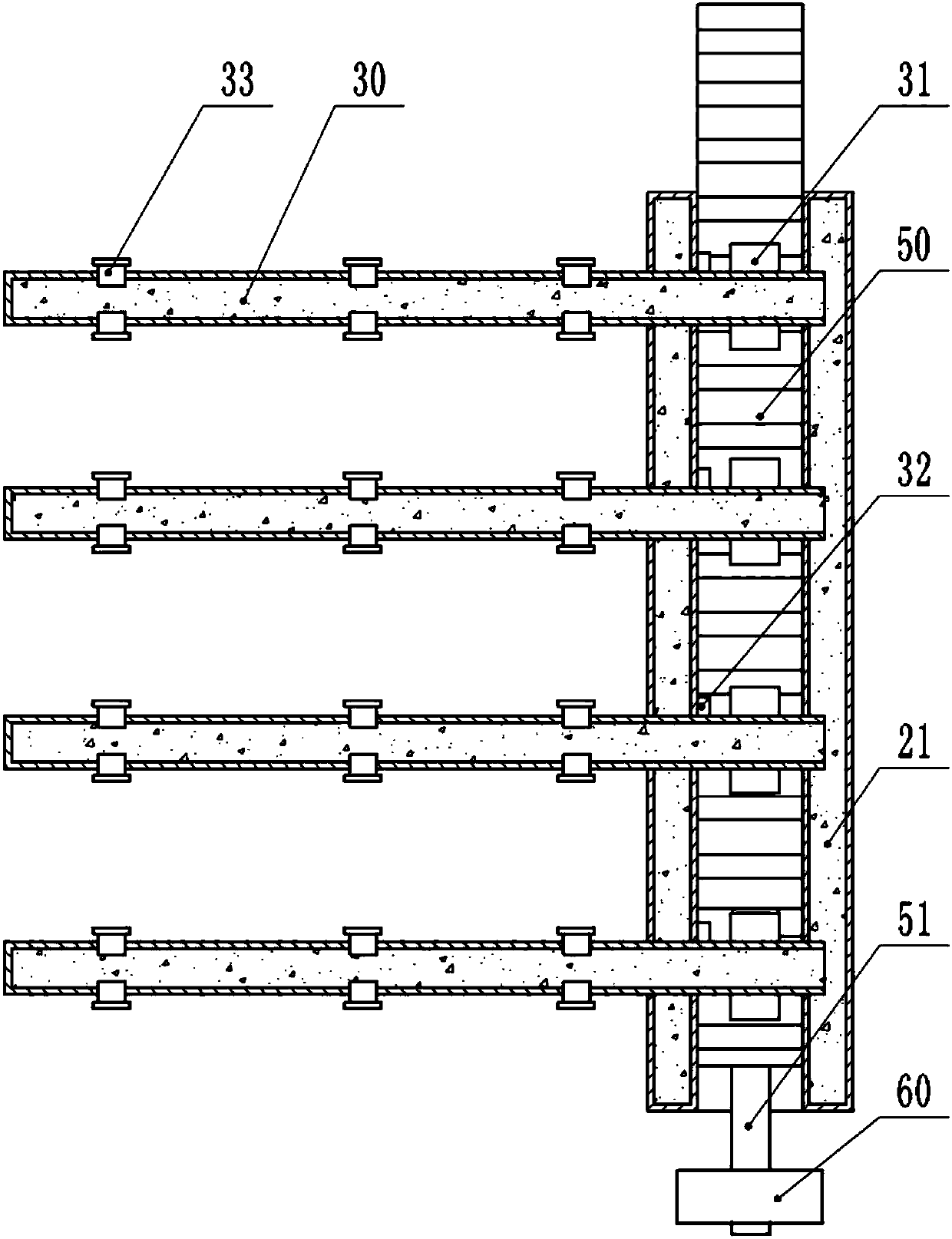

[0026] Instructions attached Figures 1 to 3 The reference signs in include: drawing trolley 10, driving gear 11, base 20, hydraulic oil 21, slide groove 22, support pipe 30, gear 31, limit block 32, support block 33, guide rail 40, rack 50 , threaded column 51, driven gear 60, driving gear 70.

[0027] Lightweight wallboard core-pulling process, the core-pulling of lightweight wallboards is operated by a core-pulling device. Such as Figure 1-Figure 3 As shown, the core pulling device includes a drawing trolley 10, a guide rail 40, a motor and a base 20 installed on the drawing trolley 10, the base 20 has a cavity filled with hydraulic oil 21, and the upper base 20 There is a sliding groove 22 on the surface, and a rack 50 is slidably connected in the sliding groove 22 . A plurality of supporting tubes 30 are rotatably connected to the base 20, and the supporting tubes 30 are located above the rack 50; one end of the supporting tubes 30 is located in the cavity and communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com