Copper lifting lug shearing and flattening device

A lifting lug and leveling technology, which is used in shearing devices, shearing machines, other manufacturing equipment/tools, etc., can solve the problems of unqualified lifting lugs, poor reliability, and difficulty in adjusting the gap between upper and lower blades, so as to improve production efficiency. and production quality, saving operating costs and time, easy disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

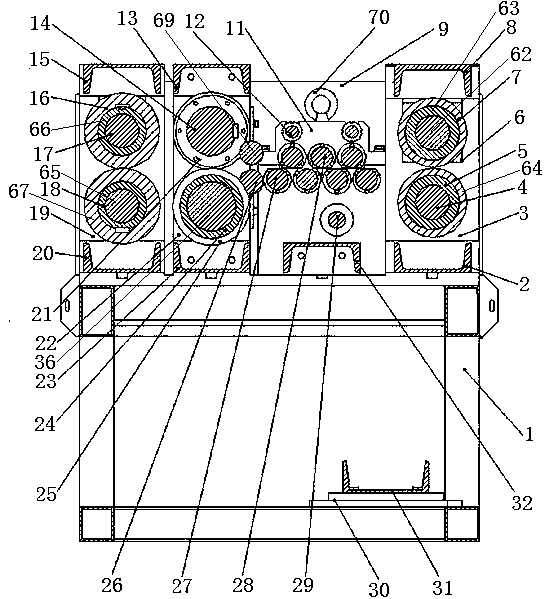

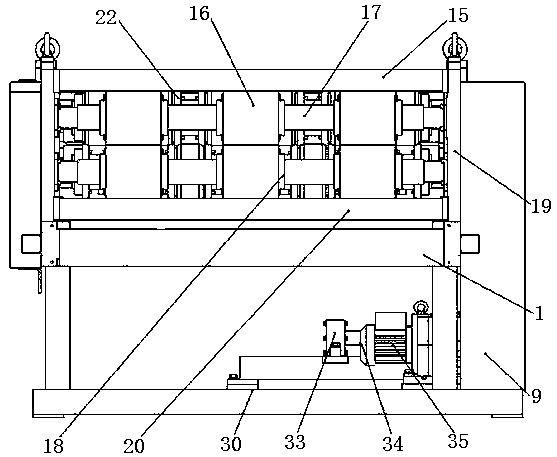

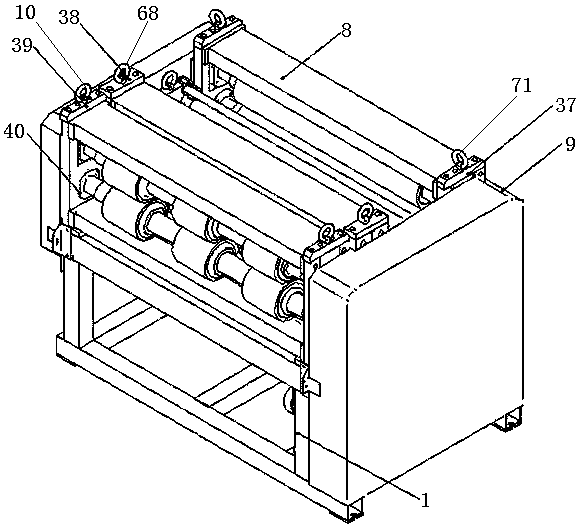

[0027] like Figure 1-6As shown, a copper lifting lug shearing and leveling device includes a frame 1 and a feed module arranged on the frame 1, a rolling shear bar module, a copper lifting lug straightening module, a flattening module and a transmission system, The feed module is arranged on the feed end of the rolling shear strip module, and the feed module includes the feed baffle 19 fixed on the left and right ends of the frame 1 and the feed roller shaft bearing seat 40 installed on the feed baffle. Upper feeding roller shaft 17 and lower feeding roller shaft 65 are installed up and down between the material roller bearing housing 40, and upper feeding roller shaft 17 is provided with three upper feeding roller shaft sleeves 66 and each upper feeding roller The shaft sleeve 66 is provided with an upper feed roller 16, and the lower feed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com