Automatic butt-joint method and device suitable for wharf oil conveying pipe loading and unloading arm and ship flange

A technology of automatic docking and loading and unloading arms, applied in metal processing equipment, image data processing, instruments, etc., can solve the problems of waste of resources, narrow space, pollution of wharf and water resource environment, etc., to improve work efficiency and economic benefits , the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

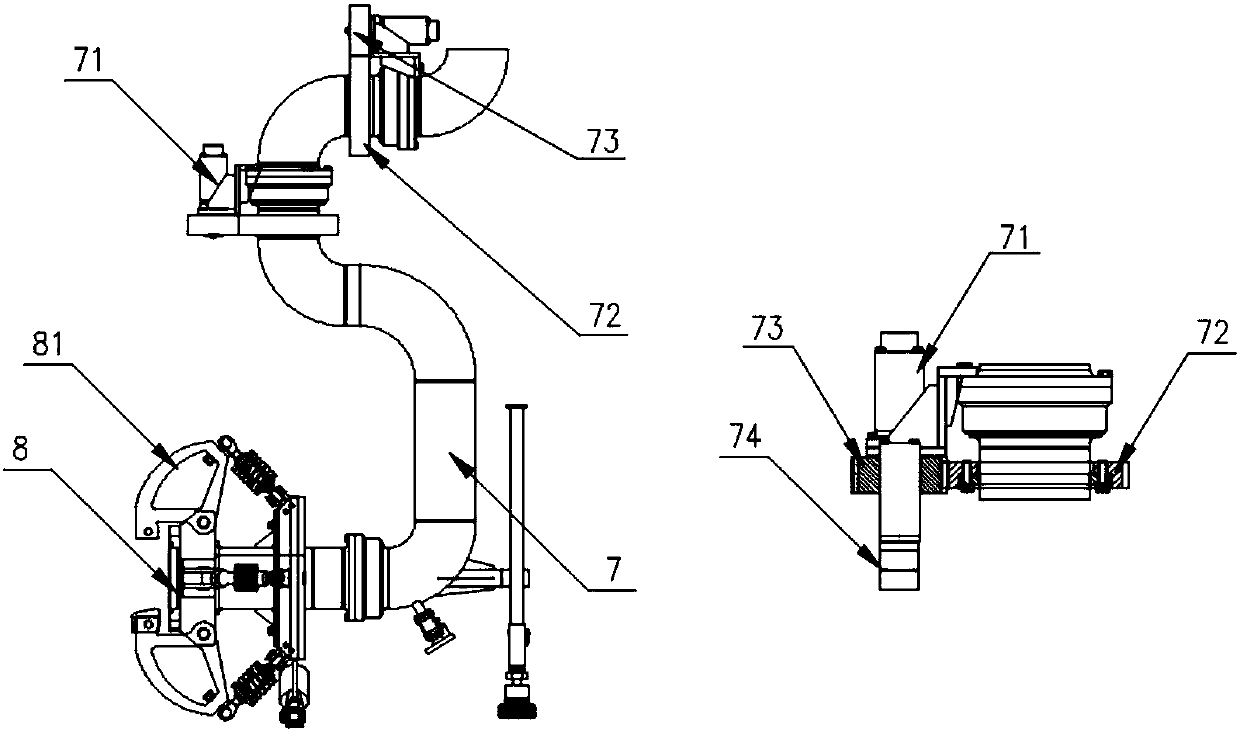

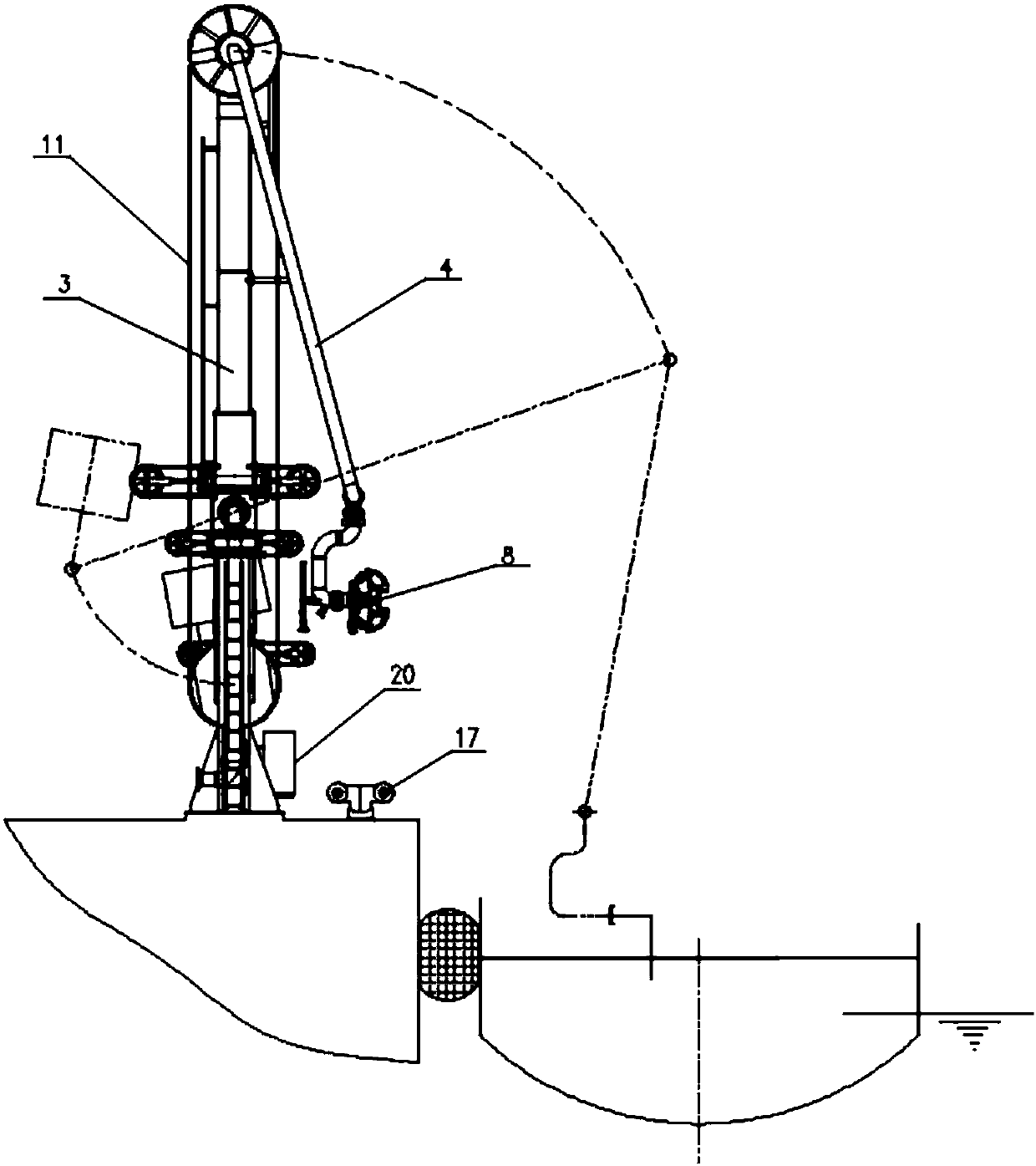

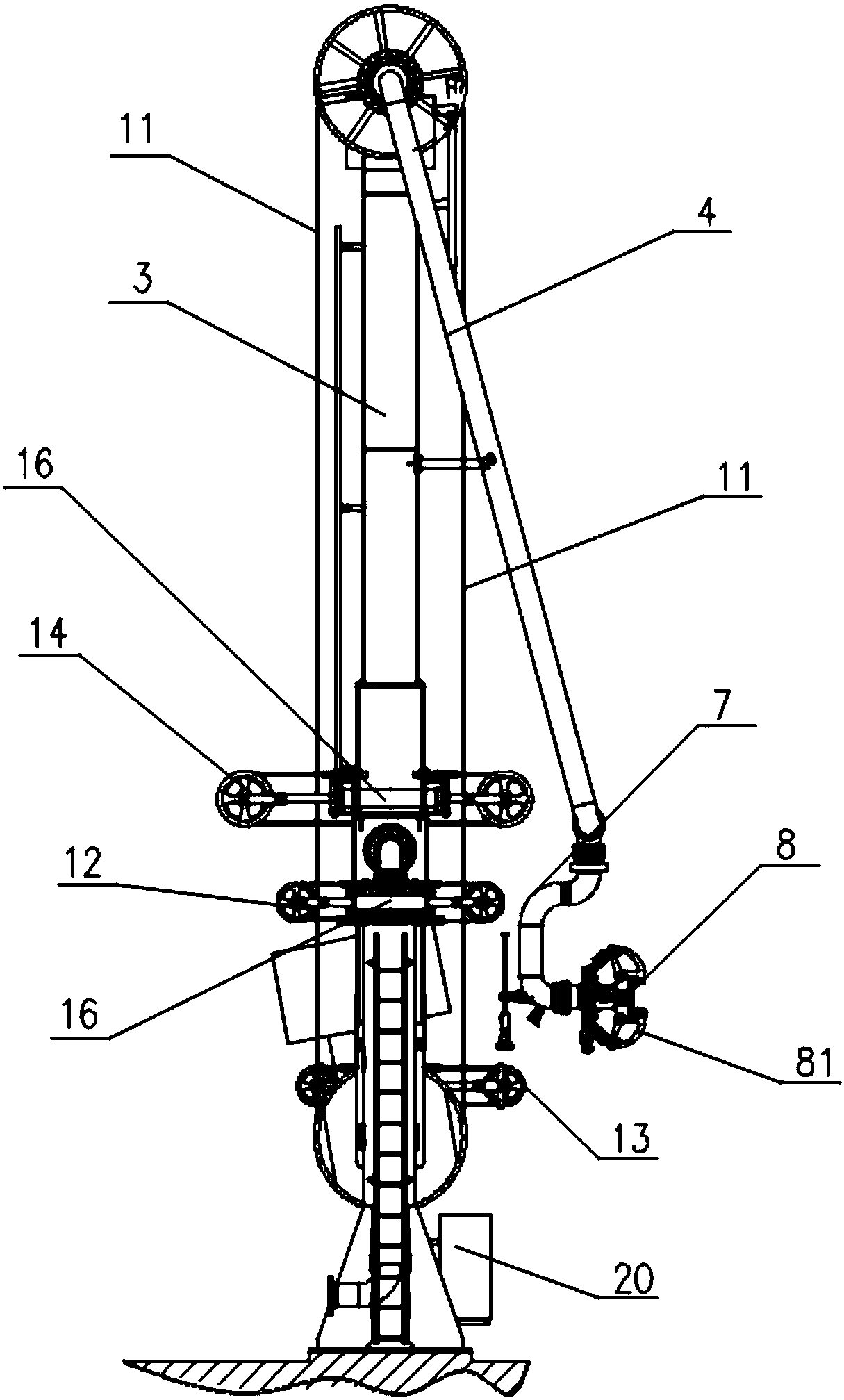

[0041] The loading and unloading arm of the oil pipeline of the present invention is double-positioned by the positioning device, and the driving device is controlled by the drive control system to drive the movement of the outer arm and the inner arm, so as to realize the precise docking of the hydraulic quick connector at the end of the outer arm of the oil pipeline arm and the flange of the ship header. As shown in Figure 1, it is suitable for the automatic docking equipment between the loading and unloading arm of the wharf oil pipeline and the flange of the ship, including: the loading and unloading arm of the oil pipeline, the base 1, the column 2, the inner arm 3, the outer arm 4, the shaft box 5, the support box 6, Three-dimensional joint 7, swing cylinder 71, large gear 72, pinion 73, encoder 74, hydraulic quick connector 8, adjustable outrigger 81, detachable elbow 9, maintenance platform 10, wire rope mechanism 11, horizontal driving device 12. Outer arm driving devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com