Automatic control method of tubular billet tail ring of perforating machine

A technology of piercing machine and capillary tube, which is applied in the direction of roll speed control, driving device for metal rolling mill, metal rolling, etc., can solve the problems of cutting the surface of the waste tube, defects of the capillary tube hole, and unavoidably scratching the surface of the mandrel, etc. Achieve the effect of meeting on-site production requirements and increasing rolling load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

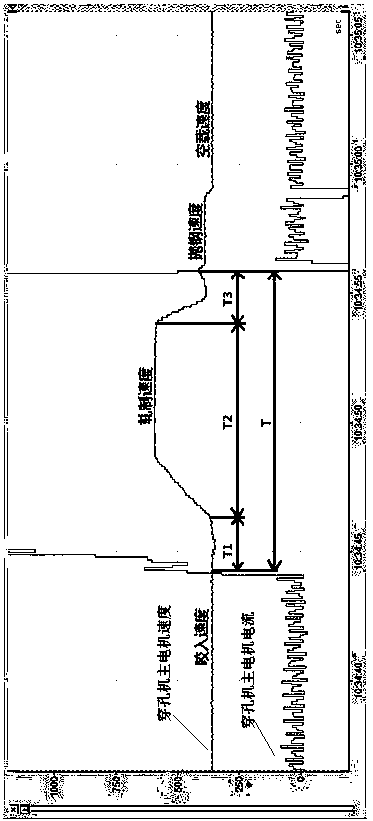

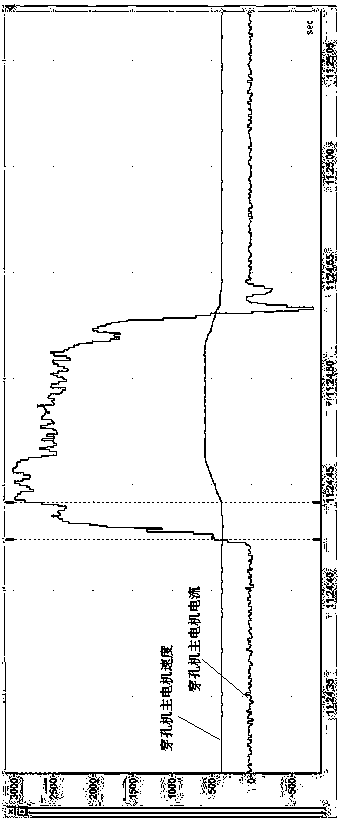

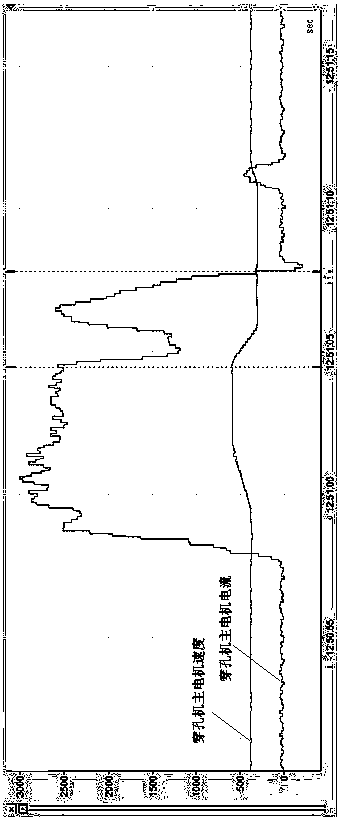

[0020] In order to reduce the shaking of the plug and control the wall thickness of the head of the capillary, the speed of the roll after biting the steel is low. After a delay of T1, the speed is increased to the rolling speed at an acceleration of 100rpm / s, and the speed is -200rpm / s when it is close to the throwing of steel. The acceleration decelerates to the steel throwing speed. After a delay of 3 seconds after steel throwing, the roll speed returns to the steel biting speed. At the moment of throwing steel, the speed of the roll is low, which reduces the shear stress of the inner and outer layer metal and eliminates the iron ear at the tail. The speed curve of the piercer roll is trapezoidal, which is called "trapezoidal rolling", such as figure 1 shown. The acceleration time T1 and deceleration time T3 are set by the operation screen, see figure 2 .

[0021] When the roll bites the steel, the current of the piercing motor rises. When the current reaches 500A, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com