Drying, crushing and mixing all-in-one machine

An all-in-one machine and drying technology, which is applied in the field of crushing and mixing operations, dry crushing and mixing machine, and drying of solid materials. It can solve the problems of difficult cleaning and sterilization, many dead angles, and low mixing efficiency, so as to reduce pollution. The risk of reducing the particle size difference, the effect of stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

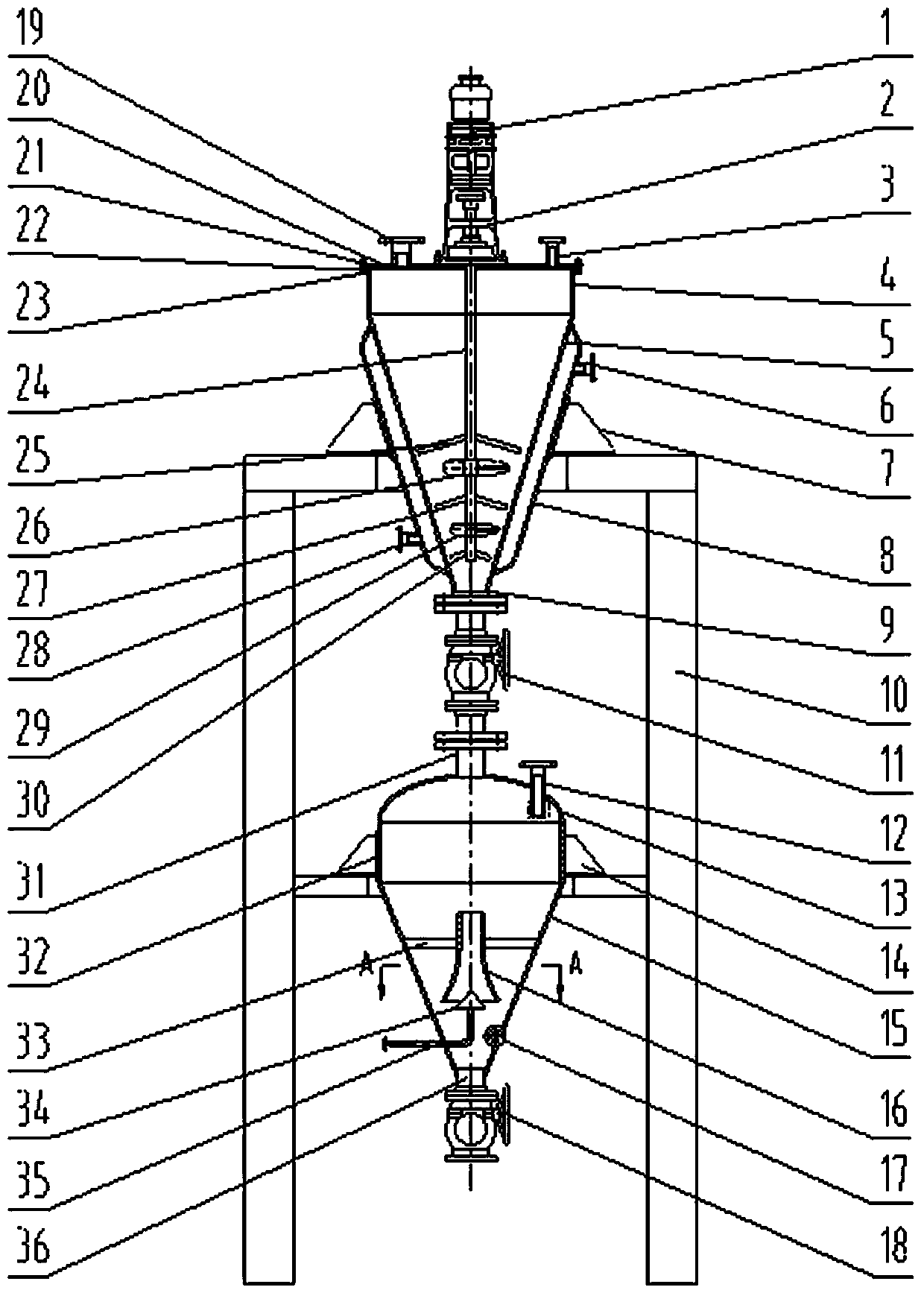

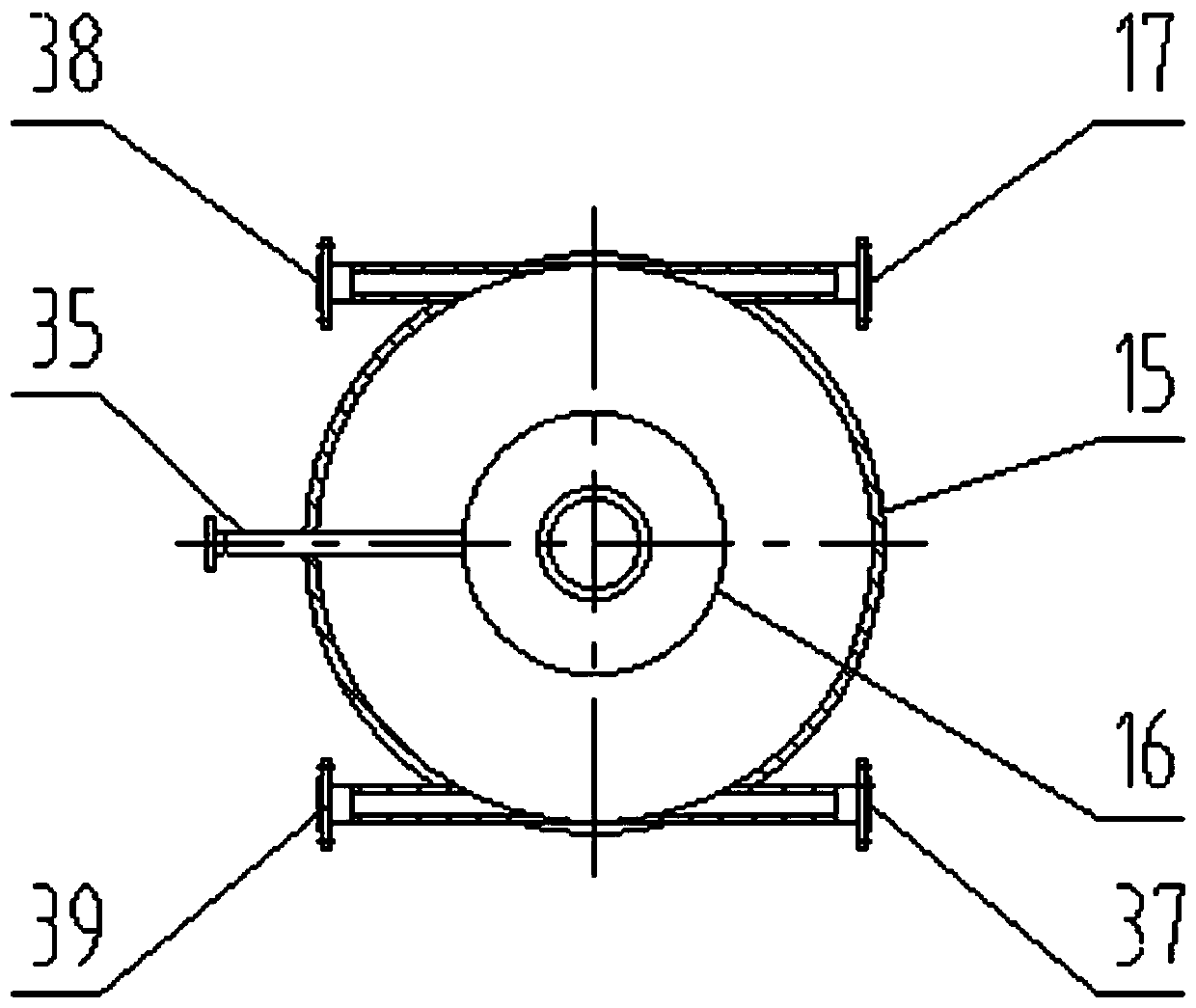

[0014] A dry crushing and mixing machine, including a dry crushing device and a mixing device, such as figure 1 As shown, the drying and crushing device includes a motor 1, a reducer 2, a vacuum port 3, an upper straight cylinder 4, an upper cone cylinder 5, a steam inlet 6, an upper lug 7, a jacket 8, an upper outlet 9, and an upper inlet 19. Upper cover plate 20, nut 21, equipment flange 22, bolt 23, rotating shaft 24, first layer blade 25, first layer turbine paddle 26, second layer blade 27, steam condensate outlet 28, second layer turbine Paddle 29 and third layer blade 30; as figure 1 with figure 2 As shown, the mixing device includes a dust removal port 12, an elliptical head 13, a lower end lug 14, a lower end cone 15, an air lift cylinder 16, a side air inlet A 17, a lower end discharge port 18, a lower end feed port 31, Lower end straight barrel 32, support plate 33, umbrella cap 34, middle air inlet 35, lower end discharge opening 36, side air inlet B 37, side ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com