Method of desulfurizing flue gas by ammonia-magnesium combination and by-producing struvite

A struvite and flue gas technology, applied in the field of ammonia-magnesium combined flue gas desulfurization and by-product struvite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

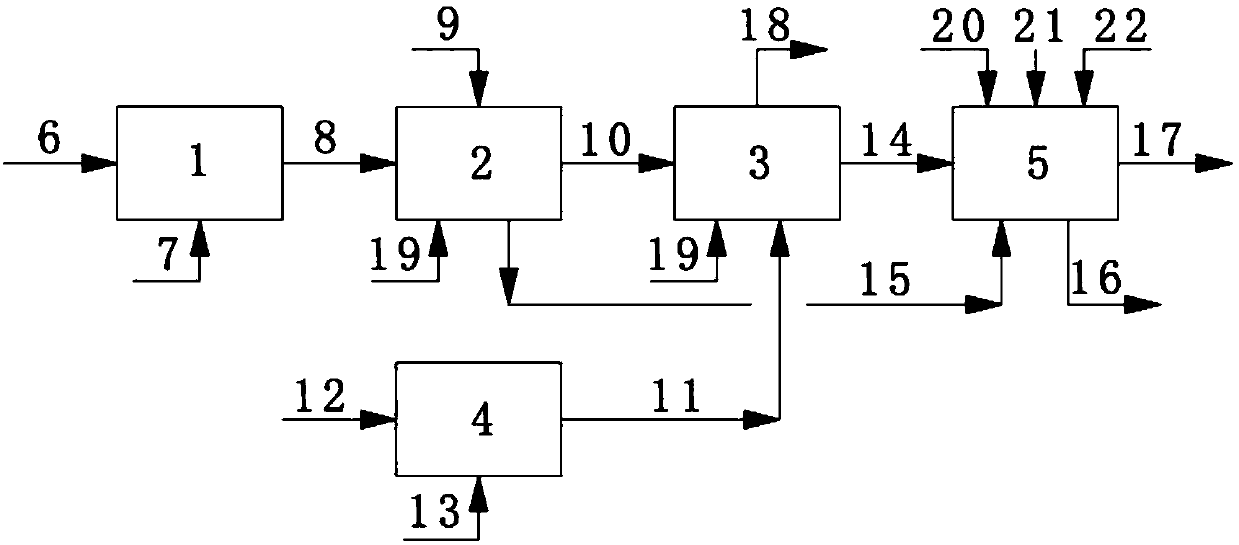

Method used

Image

Examples

Embodiment 1

[0113] Taking the treatment of 220t / h boiler flue gas as an example, the flue gas volume is 270000Nm 3 / h (flue gas volume in working condition 398600m 3 / h), inlet flue gas temperature 125°C, inlet flue gas SO 2 Concentration 2000mg / Nm 3 , absorb with ammonia water of 5% (wt) concentration, the pH value of the absorption solution is 5.0-6.3, the absorption temperature is 40-60°C, the pH value of the oxidation process is 4.5-6.5, and the amount of ammonium sulfate produced is 322.99kg / h (24468.8mol / h), the molar number of nitrogen is 4894mol / h, SO 2 The removal rate is about 29%.

[0114] SO containing after ammonia flue gas desulfurization 2 The flue gas enters the magnesium method flue gas desulfurization device, with Mg(OH) 2 Absorbed as a desulfurizer, SO 2 The removal rate is about 69% of the total. Total SO in the two-step desulfurization process 2 The removal rate is 98% of the total amount, the amount of magnesium sulfate produced is 698.625kg / h (5821.88mol / h)...

Embodiment 2

[0122] Taking the treatment of 220t / h boiler flue gas as an example, the flue gas volume is 270000Nm 3 / h (flue gas volume in working condition 398600m 3 / h), inlet flue gas temperature 125°C, inlet flue gas SO 2 Concentration 2000mg / Nm 3 , absorb with ammonia water of 5% (wt) concentration, the pH value of the absorption solution is 5.0-6.3, the absorption temperature is 40-60°C, the pH value of the oxidation process is 4.5-6.5, and the amount of ammonium sulfate produced is 322.99kg / h (24468.8mol / h), the molar number of nitrogen is 4894mol / h, SO 2 The removal rate is about 29%.

[0123] SO containing after ammonia flue gas desulfurization 2 The flue gas enters the magnesium method flue gas desulfurization device, with Mg(OH) 2 Absorbed as a desulfurizer, SO 2 The removal rate is about 69% of the total. Total SO in the two-step desulfurization process 2 The removal rate is 98% of the total amount, the amount of magnesium sulfate produced is 698.625kg / h (5821.88mol / h)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com