Acrylic acid biquaternary ammonium salt grafted non-woven fabric wet tissue and preparation method thereof

A double quaternary ammonium salt, non-woven technology, applied in pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve the problem of antibacterial properties of wet wipes, poor softness and irritation, microbial cell membrane microbial death, and needs to be further improved, etc. problem, to achieve the effect of improving the grafting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

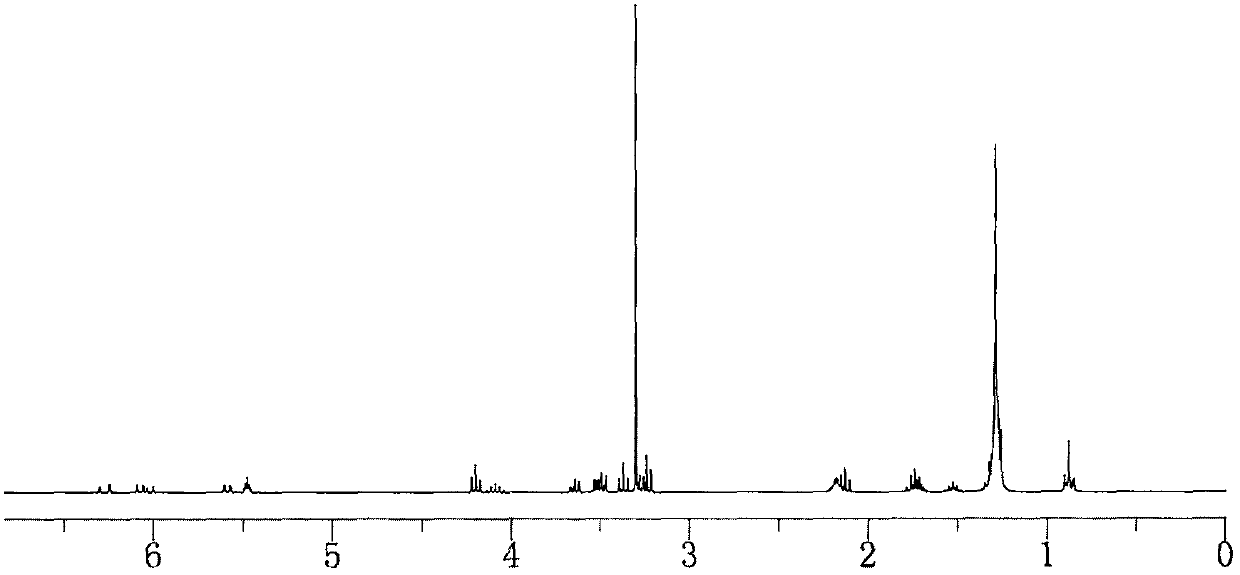

Image

Examples

preparation example 1

[0045] 1) Dry hydrogen chloride gas is introduced into the anhydrous ether solution of octadecyl dimethyl tertiary amine to produce a white precipitate. Then use water as the solvent, put epichlorohydrin in the dropping funnel, start to drop slowly, drop it in 35 minutes, stir evenly at room temperature, react at 80°C for 12h, and measure the content of epichlorohydrin quaternary ammonium salt by titration Determine the end point of the reaction. After the reaction is complete, remove the solvent by rotary evaporation at room temperature to obtain a light yellow paste residue, recrystallize the paste residue with acetone, and filter under reduced pressure after the crystals are precipitated. Repeat this several times to finally obtain a white powder. Monoquaternary ammonium salt product - intermediate product N-(3-chloro-2-hydroxypropyl)-N,N-dimethyloctadecyl ammonium chloride. Wherein, the mol ratio of octadecyl dimethyl tertiary amine: hydrogen chloride: epichlorohydrin is 1...

preparation example 2

[0056] Identical to Preparation Example 1, the difference is only: in the 1) step, use the anhydrous ether solution of dodecyl dimethyl tertiary amine, finally obtain the biquaternary ammonium salt B described in the following formula.

[0057]

Embodiment 1

[0059] The preparation method of the wet wipe body is as follows:

[0060] (1) Using bamboo pulp fibers with a length of 50 mm and a diameter of 0.08 mm as raw materials, a bamboo pulp non-woven fabric is obtained after cross-lapping and spunlace technology, and a non-woven fabric carrier with a thickness of 4 mm is obtained after cutting and high-temperature sterilization ;

[0061] (2) Place the non-woven fabric carrier prepared in step (1) in the monomer solution prepared by 1L isopropanol / water mixed solvent, and soak for 24 hours in the dark at room temperature; the monomer is diquaternary ammonium salt A and Potassium hydroxide neutralization degree is 65% acrylic acid, the mass fraction of bisquaternary ammonium salt A in the monomer solution is 0.1%, and the molar ratio of bisquaternary ammonium salt A and (acrylic acid+acrylic acid salt) is 25: 1. The volume ratio of isopropanol to water is 3:1;

[0062] (3) Under nitrogen protection, add CeCl to the monomer solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com