Semi-automatic machine for removing lotus plumules from fresh lotus seeds

A semi-automatic, core-piercing machine technology, applied in food science, applications, fruit pitting devices, etc., can solve the problems of low efficiency of core-piercing for fresh lotus seeds, and achieve the effect of excellent appearance, high integrity rate, and guaranteed coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

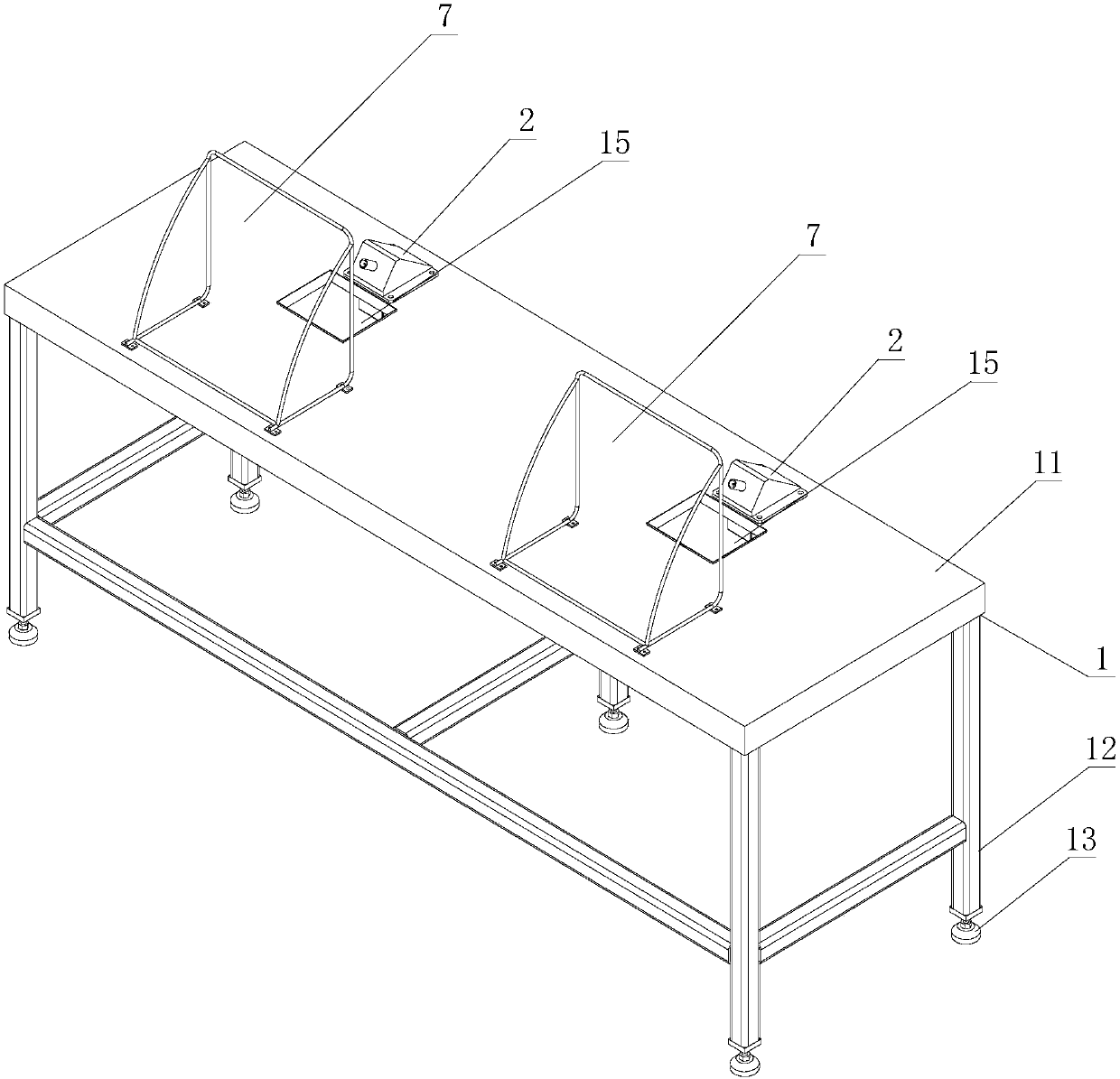

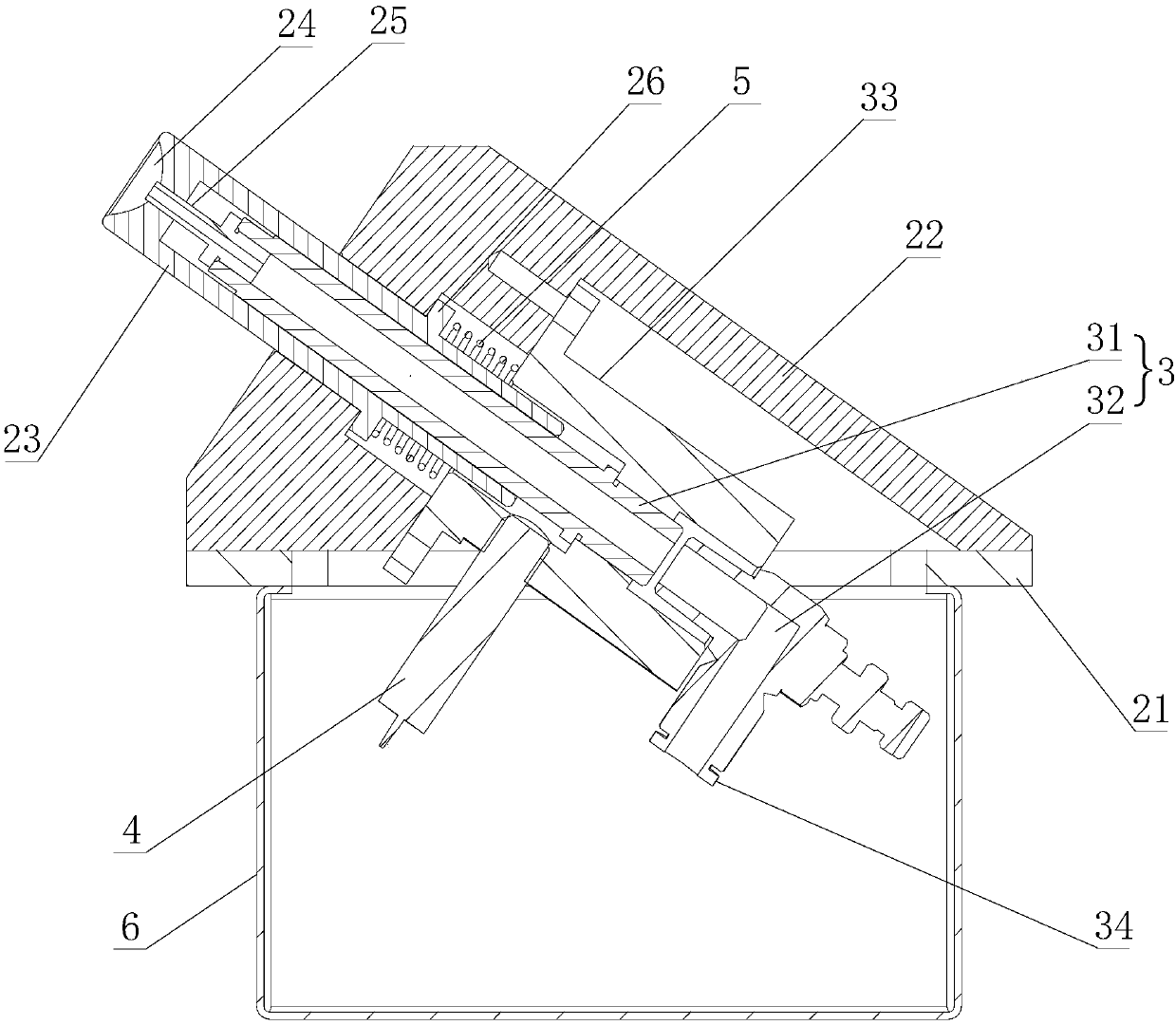

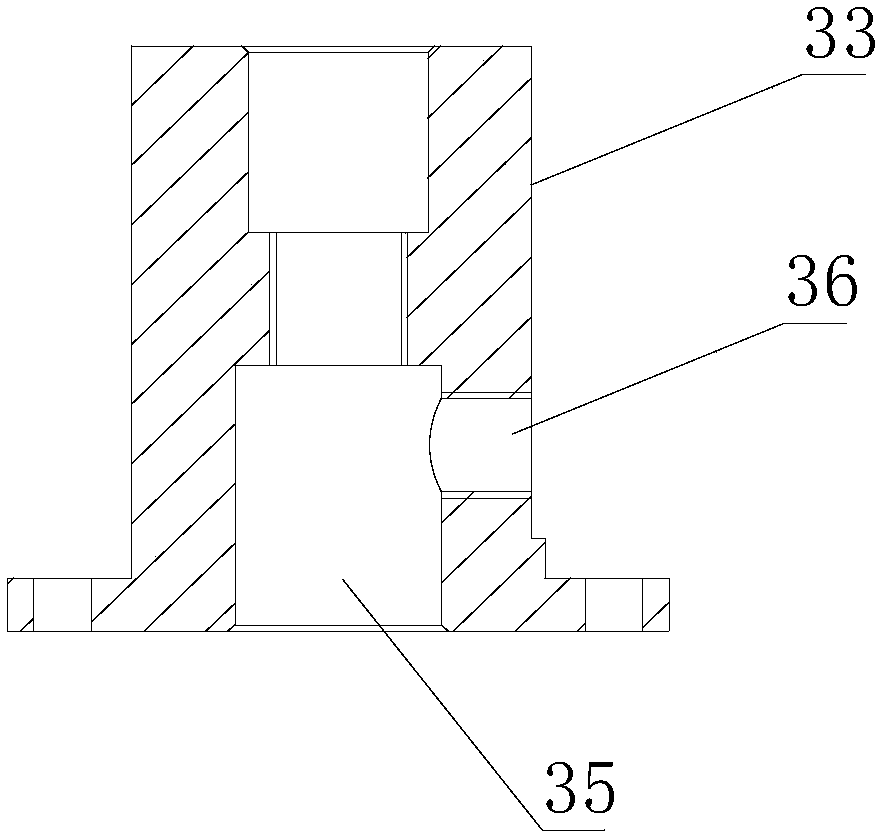

[0022] like figure 1 , figure 2 , image 3 As shown, a semi-automatic core-piercing machine for fresh lotus seeds includes a frame 1 and a semi-automatic core-piercing machine assembly 2 arranged on the frame 1, and the semi-automatic core-piercing machine assembly 2 includes a fixed plate 21 and an inclined Block 22, the inclined block 22 is provided with a movable rod cover 23, the movable rod cover 23 is provided with a positioning groove 24 positioned at one end of the lotus seeds, and the positioning groove 24 is provided with a top 25 that is arranged in a middle-pass structure in the middle, and the lotus seeds are close to the positioning groove 24 Finally, rely on the operator to gently press the plug 25 to penetrate the surface of the lotus seeds, and move synchronously with the movable rod sleeve 23. The plug 25 is connected to the inflatable component 3, and the lotus seeds rely on the inflatable component 3 to fill the lotus seeds with high-pressure gas to force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com