a fes 2 Preparation method and application of composite material with s

A technology for composite materials and cathode materials, which is applied in the field of preparation of FeS2 and S composite materials, can solve problems such as the shuttle effect, achieve the effects of reducing the shuttle effect, simple preparation method, and low raw material price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

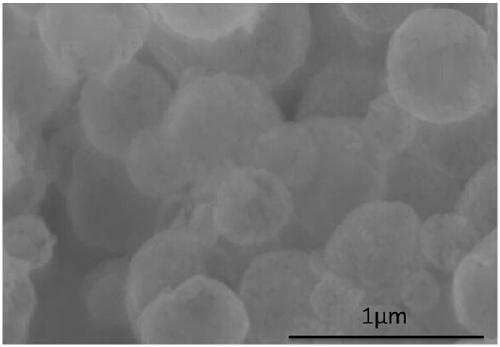

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment 1: This embodiment describes a kind of FeS 2 And the preparation method of S composite material, described method step is as follows:

[0020] Step 1: Take 1-10 mmol of iron salt and add it to 25-250 mL of methanol and stir to fully dissolve it, which is recorded as solution 1; take 4-40 mmol of 2-methylimidazole and 0.3-1.5 g of polyvinylpyrrolidone (PVP) Add it into 25 mL of methanol and stir to fully dissolve it, and record it as solution 2; add the above solution 1 dropwise into solution 2 and stir for 5-10 minutes, then let it stand for 12-48 hours, and centrifuge at a speed of 8000-10000r / min for 5- Collect the precipitate for 10 minutes, wash it with methanol for 5 times, put it in a drying oven, and dry it at 60-70°C for 24 hours to obtain the iron-based zeolite-type imidazole framework compound (Fe-ZIF);

[0021] Step 2: Take the iron-based zeolite-type imidazole framework compound and elemental sulfur prepared in step 1 according to the ma...

specific Embodiment approach 2

[0023] Specific embodiment two: a kind of FeS described in specific embodiment one 2 and the preparation method of S composite material, in step 1, described iron salt is FeSO 4 •7H 2 O, FeCl 2 4H 2 O or Fe(NO 3 ) 2 ·6H 2 One of O.

specific Embodiment approach 3

[0024] Specific embodiment three: a kind of FeS described in specific embodiment one 2 and S composite materials, in step 2, the heating rate before 400°C is 1°C / min, 2°C / min or 5°C / min, and the heating rate between 400 and 500°C is 5°C / min or 10°C °C / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com