Automatic cable production device

An automatic production and cable technology, applied in cable/conductor manufacturing, insulation of conductors/cables, circuits, etc., can solve problems such as concave or convex hull of air hole covering layer, lack of detection link, insulation layer pinhole, etc., to avoid detection dead angle. , The cooling effect is good, the effect of ensuring the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

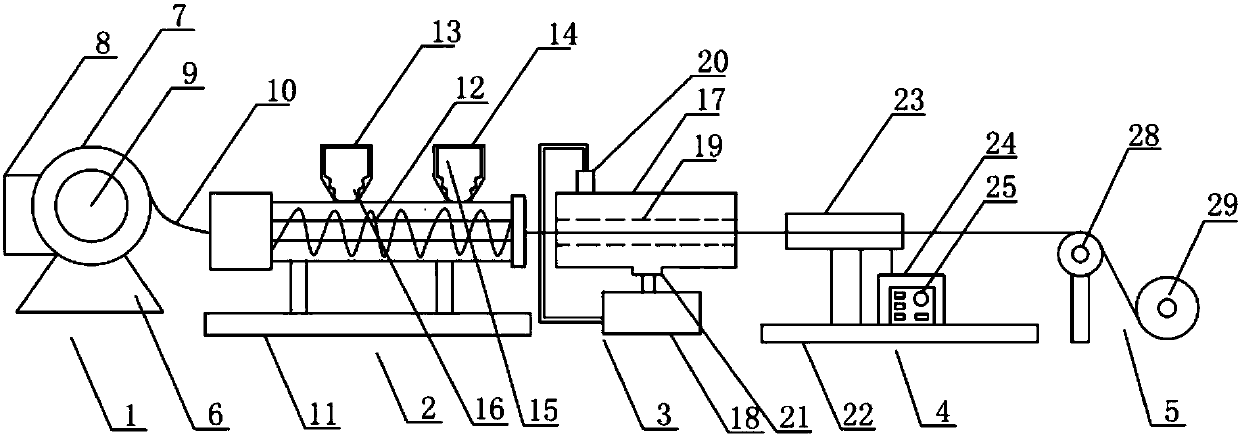

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

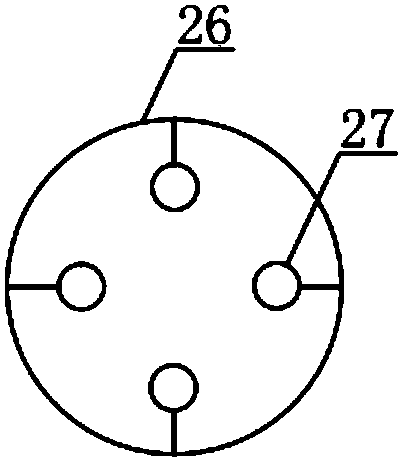

[0027] Such as Figure 1-2 As shown, a kind of automatic production cable equipment of the present invention comprises feeding device 1, extruding device 2, cooling device 3, detection device 4 and winding device 5, and described feeding device 1 includes pay-off bracket 6, pay-off reel 7 And drive motor 8, described pay-off reel 7 is arranged on the pay-off support 6, and the middle part of pay-off reel 7 is provided with rotating shaft 9, is wound with cable core 10 on the rotating shaft 9, described rotating shaft 9 and drive motor 8 connected, the extrusion device 2 includes a base 11 and an extruder body 12 arranged above the base 11, the top of the extruder body 12 is sequentially provided with a first feeding hopper 13 along the moving direction of the cable core 10 And the second feed hopper 14, the first hopper 13 is filled with insulation material, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com