Agitator and using method of agitator

A technology of mixer and layer stirring, applied in mixers with rotary stirring devices, chemical instruments and methods, applications, etc., can solve the problems of small stirring amount, uneven stirring, time-consuming and laborious, etc., and achieve uniform stirring, simple structure, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described below in conjunction with the accompanying drawings.

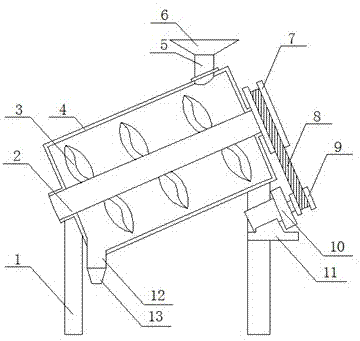

[0024] figure 1 It is a structural schematic diagram of the present invention.

[0025] The present invention includes a pillar 1, a cylinder 4 and a motor 10, wherein the cylinder 4 is arranged obliquely on the pillar 1, the angle between the cylinder 4 and the horizontal plane is 50-70 degrees, the cylinder 4 is provided with a rotating shaft 2, and the rotating shaft 2 Multi-layer stirring blades 3 are arranged on the top, a motor platform 11 is arranged on the pillar 1, and a motor 10 is arranged on the motor platform 11. One end of the rotating shaft 2 passes through the cylinder body 4 and a turntable 7 is fixedly arranged at the end, and the turntable 7 and the motor 10 8 drive connections between conveyor belts. One side upper part of cylinder body 4 is provided with feed pipe 5 and feed funnel 6, and the bottom of the other side of cylinder body 4 is provided with d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com