Weighable rail

A track and weighing technology, which is applied in the direction of weighing, measuring devices, instruments, etc., can solve the problems of affecting the hoisting efficiency, long construction period, and inability to obtain information on the unbalanced load of the track, so as to improve work efficiency and reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

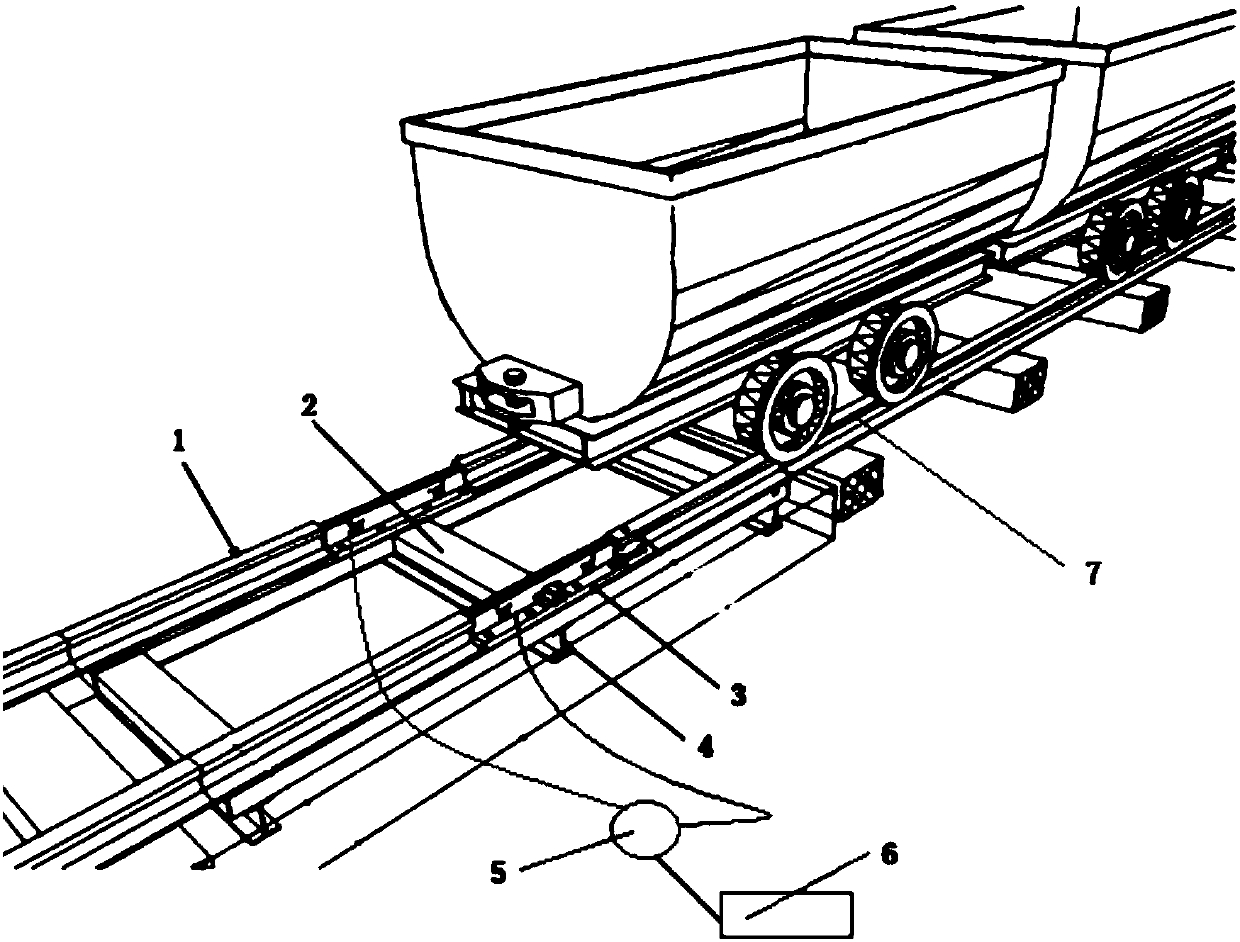

[0014] This embodiment discloses a weighable rail (such as figure 1 shown), the guide rail 1 of the rail (in the field of vehicle rail transportation, the straight line that the turnout of the track connects the switch is called the guide rail, and each section of the guide rail is made up of two parallel and equal-length straight tracks, and the guide rail By changing the opening direction of the railway switch to change the direction of train running), ground beams 4 are arranged between), and two load cells 3 are symmetrically arranged on the two tracks of the guide rail 1; the two load cells 3 Between and above the ground beams 4, a weighing frame 2 for bearing the weight is arranged; the rails are connected with a weighing display device for displaying weighing values.

[0015] Preferably, the weighing display device includes a signal integration device 5 for sorting out the signals of the weighing sensors, and a digital display instrument 6 for displaying the measured we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com