Novel vertical unsealed self-priming pump

A sealless, self-priming pump technology, applied in the engineering field, can solve problems such as poor sealing performance and poor reliability, and achieve the effects of increasing self-balancing ability, reliable sealing, and improving support stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

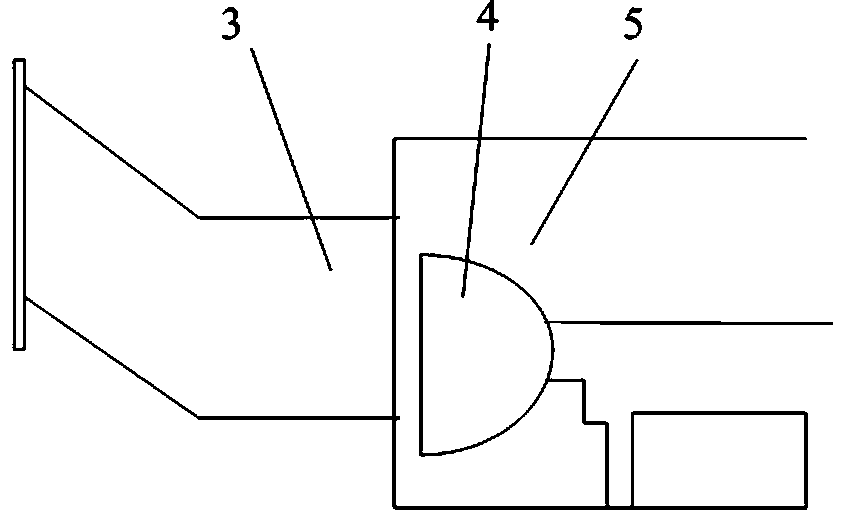

[0013] Preferably, when the pump is working, the high-pressure liquid from the outlet of the impeller enters the flow channel of the auxiliary outer wheel through the sealed cavity, and at the same time, due to the rotation of the auxiliary impeller, the liquid in the flow channel forms a liquid ring with a certain thickness. When the pump is running, The centrifugal pressure generated by the liquid ring will be balanced with the pressure of the medium around the auxiliary impeller, ensuring that the thickness change of the liquid ring is carried out in the flow channel of the auxiliary impeller, the balance state will not be destroyed, and the medium will not leak sideways, increasing the Based on this sealing principle, the vertical self-priming pump realizes the reliable sealing of the rotating shaft, which can meet the needs of high-temperature and impurity-containing liquid transportation.

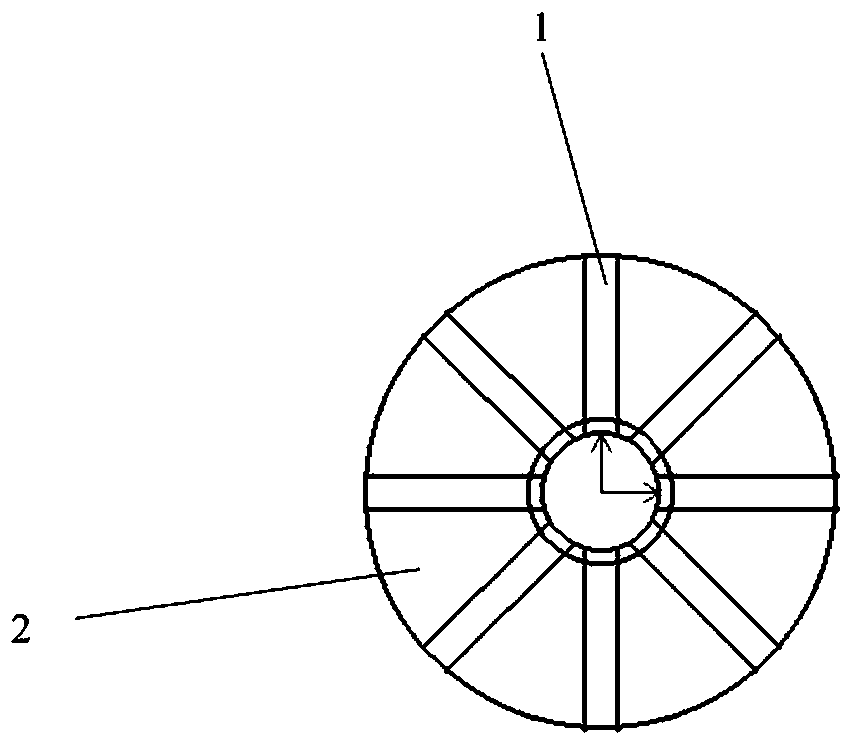

[0014] Preferably, a structure of 10 blades is used, and the auxiliary impeller is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com