Muffler allowing quick replacement of mesh filter

A muffler and mesh technology, which is applied in the direction of muffler devices, machines/engines, engine components, etc., can solve problems such as new product development, inconvenient processing and manufacturing, and inability to meet the performance requirements of engines and mufflers, so as to facilitate diversification, The effect of convenient production and convenient debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

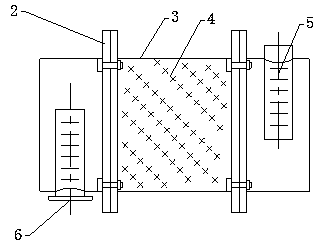

[0012] Such as figure 1 As shown, the muffler that can quickly replace the mesh corrugator includes a barrel body 1, a flange end cover 2, a flange body 3, a mesh filter 4, an air outlet pipe 5, and an air inlet pipe 6. The flange body 3 and the barrel body 1 are fixedly connected, the outlet pipe 5 and the intake pipe 6 are installed on the barrel body 1, the mesh filter is installed in the flange body 3, and the flange end cover 2 and the flange body 3 connections.

[0013] The flange end cover 2 and the flange body 3 are connected by bolts.

[0014] Four circular holes are evenly distributed on the flange end cover 2 and the flange body 3 .

[0015] A sealant is used between the outlet pipe 5, the air inlet pipe 6 and the staving 1.

[0016] During use, when the mesh filter 4 needs to be replaced or installed, the bolts are removed, and the mesh filter 4 is take...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com