Well mouth anti-corrosion diverter

A diverter and diversion hole technology, which is applied in wellbore/well components, earthwork drilling, sealing/packing, etc., can solve the problems of difficult high-pressure oil and gas layered well operations, avoid well control imbalance, reduce The effect of affecting and reducing the probability of occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

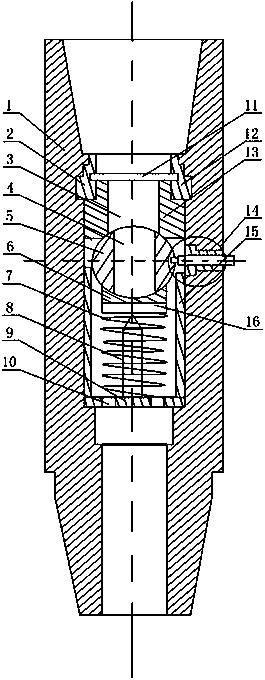

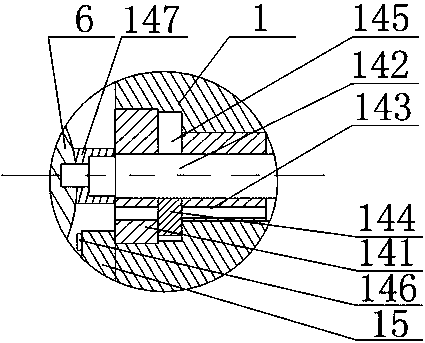

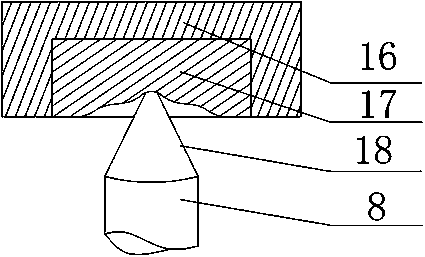

[0024] Such as Figure 1~3As shown, this embodiment includes a body 1, a support plate 9, a sphere 5 and an upper ball seat 13, and a liquid inlet 3 is opened inside the body 1, and the support plate 9 is fixed on the lower part of the liquid inlet 3, and the upper The ball seat 13 is fixed on the upper part of the liquid inlet hole 3 and its inside is connected with the liquid inlet hole 3. A support shaft 8 is arranged in the middle part of the support plate 9. The spring 7 is sleeved on the support shaft 8. There are a plurality of The small hole 10, the top of the spring 7 is provided with a limit plate 16, and there is a gap between the bottom of the limit plate 16 and the top of the support shaft 8, the upper end of the support shaft 8 is provided with an elastic cone point 18, and the bottom surface of the limit plate 16 is embedded with The rubber block 17 facing the conical point 18, the lower ball seat 6 is fixed on the limit plate 16, a spherical blowout prevention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com