Heat-resisting anti-creep ultra-high molecular weight polyethylene fiber ultraviolet radiation crosslinking device

A polyethylene fiber, ultra-high molecular weight technology, used in fiber processing, light/infrared/X-ray fiber processing, textiles and papermaking, etc. Performance guarantee, improved bonding tightness, improved treatment uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

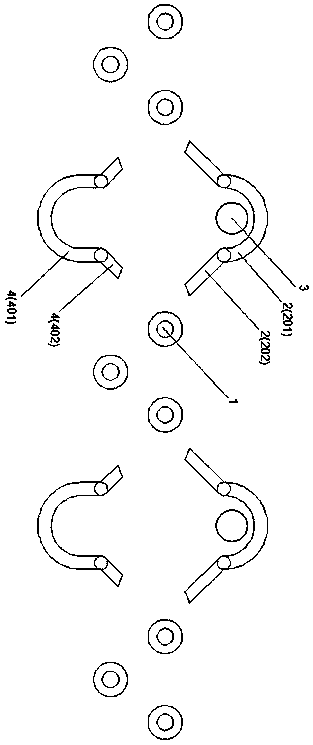

[0015] Such as figure 1 A heat-resistant and creep-resistant ultra-high molecular weight polyethylene fiber ultraviolet radiation crosslinking device shown, which includes multiple sets of transmission rollers 1, and ultraviolet radiation arranged on any two adjacent transmission rollers Device, the ultraviolet light radiation device includes a radiation cover 2 adopting a "U" shape structure, and an ultraviolet light source 3 arranged inside the radiation cover 2; each ultraviolet light radiation device is correspondingly provided with its vertically opposite The reflective tile 4 adopts a "U"-shaped structure; the ultraviolet radiation device and the corresponding reflective tile 4 are respectively arranged on the upper side and the lower side of the polyethylene fiber transmission position.

[0016] As an improvement of the present invention, among the ultraviolet radiation crosslinking devices of the heat-resistant and creep-resistant ultra-high molecular weight polyethyle...

Embodiment 2

[0019] As an improvement of the present invention, in the ultraviolet radiation device, the radiation cover 2 includes a radiation base 201 adopting a "U" shape structure, and extending towards the polyethylene fiber transmission position through both ends of the radiation base respectively. The radiation end plate 202, and the radiation end plate 202 and the radiation base 201 are connected to each other through a rotating shaft. With the above technical solution, the coverage of the radiation cover can be adjusted in real time through the setting of the radiation end plate, so that the ultraviolet radiation device in this application can be adjusted according to the actual transmission conditions of the ultra-high molecular weight polyethylene fibers , so that it can meet different processing needs. The rotating shaft between the radiation base and the radiation end plate is driven to rotate by a driving motor.

[0020] As an improvement of the present invention, the extens...

Embodiment 3

[0023] As an improvement of the present invention, the reflective tile 4 includes a reflective base 401 in a "U" shape, and reflective end plates 402 extending towards the polyethylene fiber transmission position through both ends of the reflective base 401 respectively. The end plate 402 is connected to the reflective base 401 through a rotating shaft; the length of the reflective end plate 402 is 1 / 2 to 1 times the height of the reflective base 402 . Adopting the above-mentioned technical scheme, it can adjust the angle range of the reflective tile relative to the ultraviolet light radiation device through the setting of the reflective end plate in the reflective tile, so that it can cooperate with the angle adjustment of the above-mentioned ultraviolet light radiation device so that Its applicability can be further increased. The rotating shaft between the reflection base and the reflection end plate is driven to rotate by a driving motor.

[0024] The remaining features a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com