Washing machine with wear-free washing function and control method thereof

A control method and a washing machine technology, applied in the field of washing machines, can solve the problems of wear, falling off of decorative objects, inconvenience in use, etc., and achieve the effects of increasing the amount of spray water, saving the time of water intake, and improving the washing ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

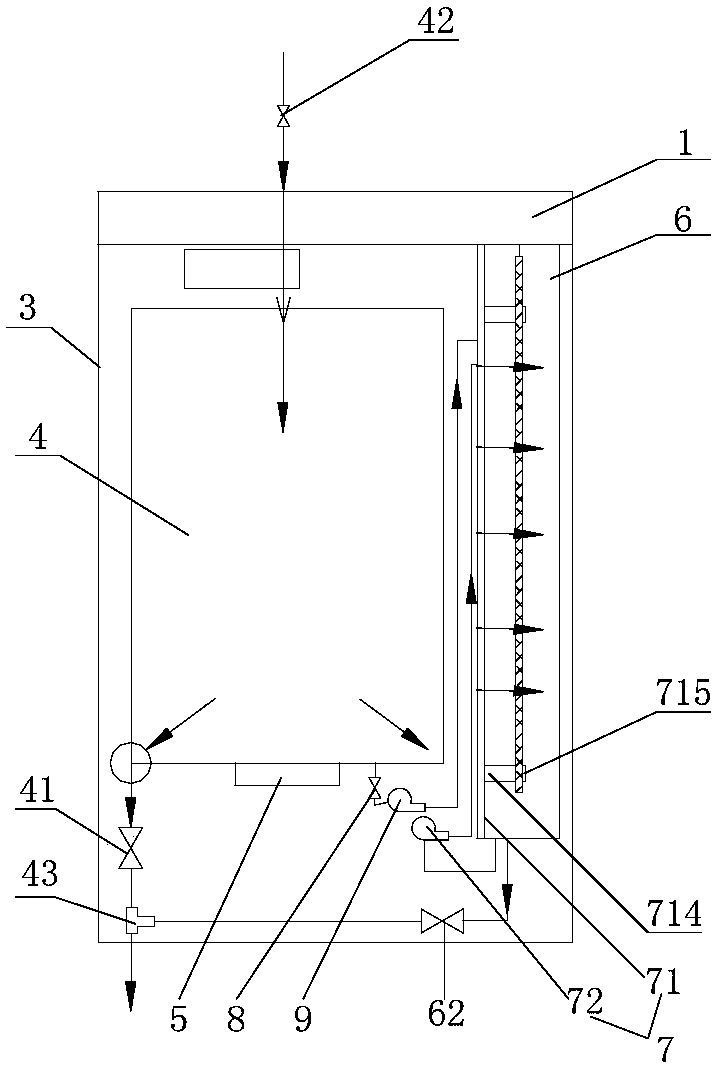

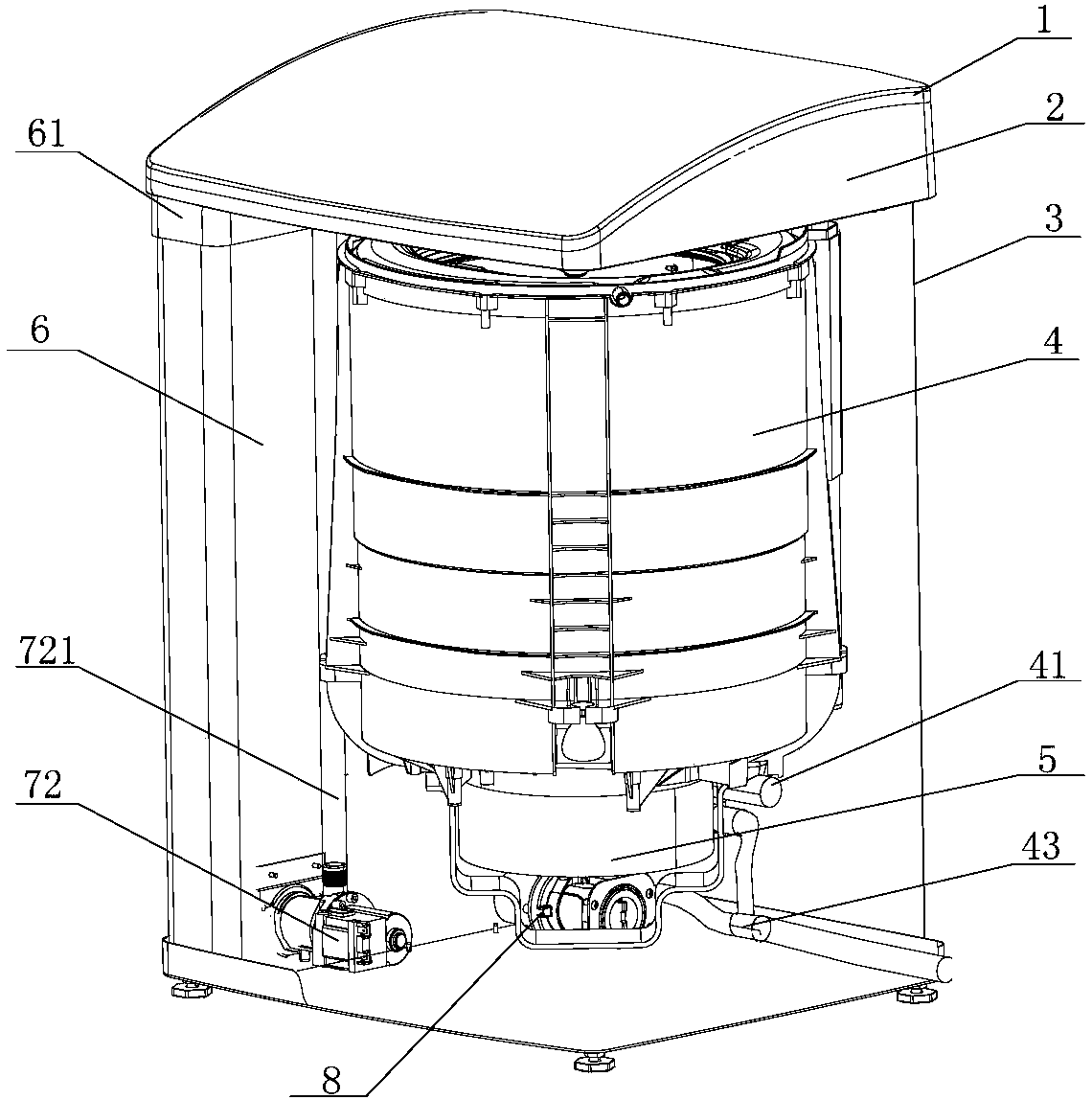

[0057] In this embodiment, a washing machine for wear-free washing is proposed. It includes a washing machine body and a housing 3. The washing machine body has a water inlet unit and an outer tub 4, and also includes a washing cabinet 6 for hanging clothes and a high-pressure sprayer for washing hanging clothes. The shower assembly 7, the washing cabinet 6 is installed on one side of the outer tub 4 and communicates with the outer tub 4 through a water guiding unit. The water inlet unit, the outer tub 4 and the water guiding unit of the washing machine body constitute the washing cabinet 6 The water inlet structure, the high-pressure spray assembly 7 is the internal circulation spray cleaning structure of the washing cabinet 6 ( figure 1 The direction of the middle arrow is the direction of water flow).

[0058] In the above technical solution, when the user wants to perform ordinary washing on the clothes, he can press the ordinary washing button of the upper cover 1, and then t...

Embodiment 2

[0080] The main components of the washing machine of the present invention include:

[0081] The upper cover 1 is convenient for users to open and pick up and put clothes.

[0082] The disk base 2 has an upper cover 1 installed on the upper part of the disk base 2, and the lower part is connected to the housing 3.

[0083] Shell 3 is the skeleton of the washing machine.

[0084] The outer tube 4 is used for holding water, and an inner tube is installed inside for storing laundry.

[0085] The solenoid valve 42 opens the solenoid valve 42 and the tap water enters the outer tub 4 of the washing machine through the solenoid valve 42.

[0086] Motor 5, driven, washing the rotation of the inner tub, washing and drying clothes.

[0087] The first drain valve 41 discharges the washing / rinsing waste water inside the washing machine after washing / rinsing of the clothes in the washing tub 4 is completed.

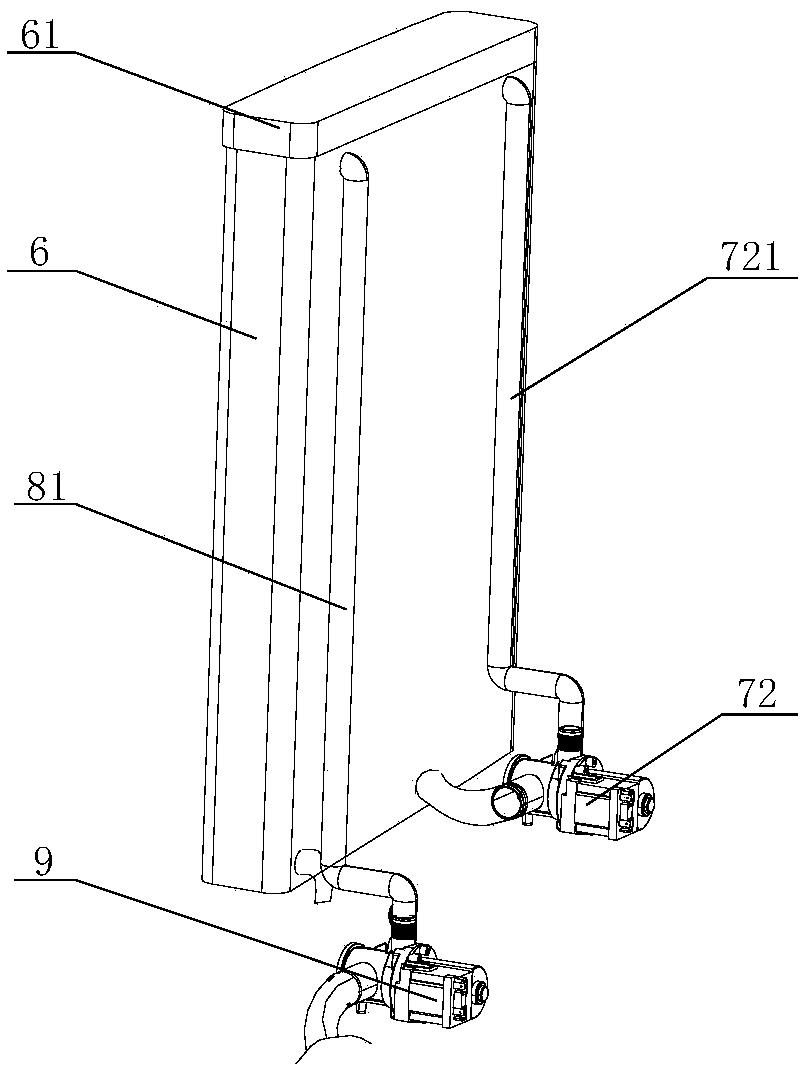

[0088] The washing cabinet 6 is installed on the side of the outer cylinder 4. The width of th...

Embodiment 3

[0104] Such as Figure 8 As shown, this embodiment proposes a method for controlling a wear-free washing washing machine, and the steps include:

[0105] S1: When it is detected that the wear-free washing button is pressed, the water inlet structure of the washing cabinet is used to inject water into the washing cabinet;

[0106] S2: After the washing tank is filled with water, start the high-pressure pump to perform internal-circulation high-pressure spray washing;

[0107] S3: After washing is completed, the washing wastewater is discharged.

[0108] Preferably, the steps further include:

[0109] S4: After the washing procedure is finished, use the water inlet structure of the washing cabinet to inject water into the washing cabinet;

[0110] S5: After the washing tank is filled with water, start the high-pressure pump to perform the internal circulation high-pressure spray rinsing;

[0111] S6, after rinsing is completed, the rinsing wastewater is discharged;

[0112] S7: After the rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com