Special clamping equipment for double-sided pressing of plate workpieces

A technology for clamping equipment and workpieces, applied in metal processing equipment, metal processing machinery parts, clamping, etc., can solve the problem that the pressing force on both sides cannot be guaranteed to be exactly the same, the force exerted by the staff is not well controlled, and the milling groove is affected and punching effect, to achieve the effect of saving raw materials and labor costs, novel structure and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

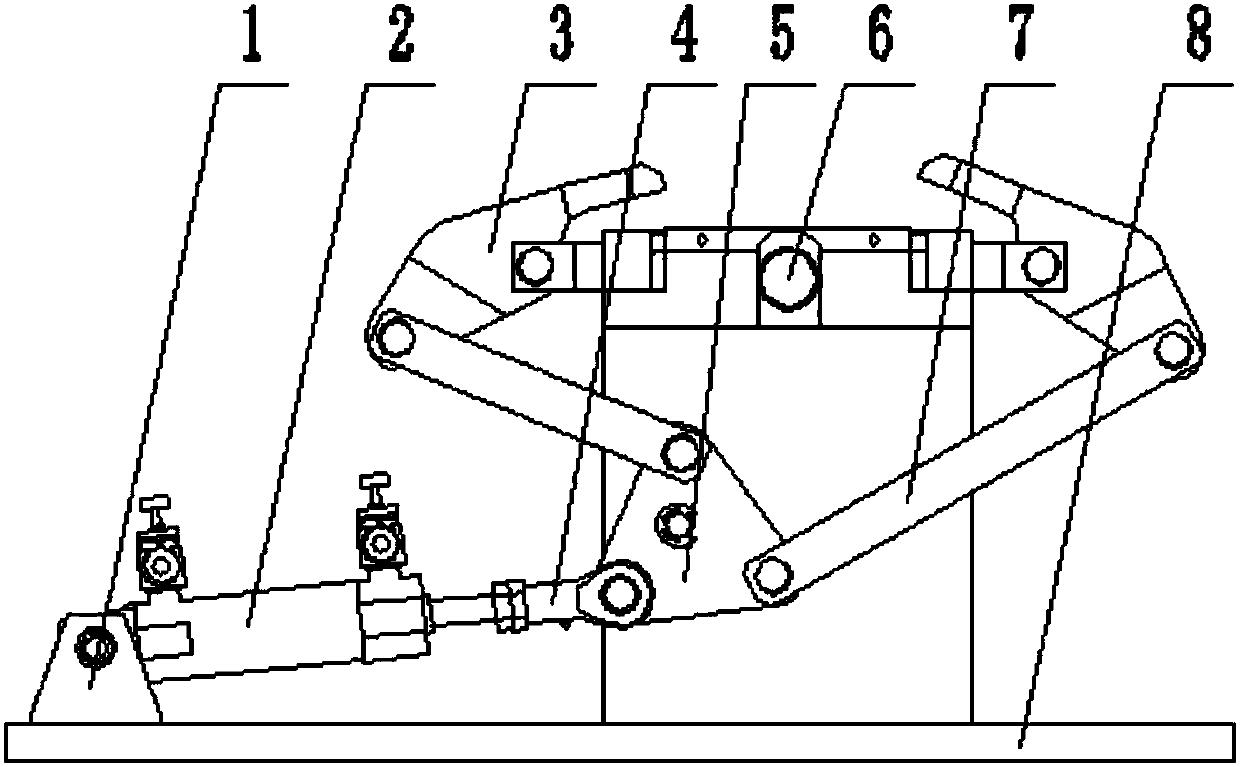

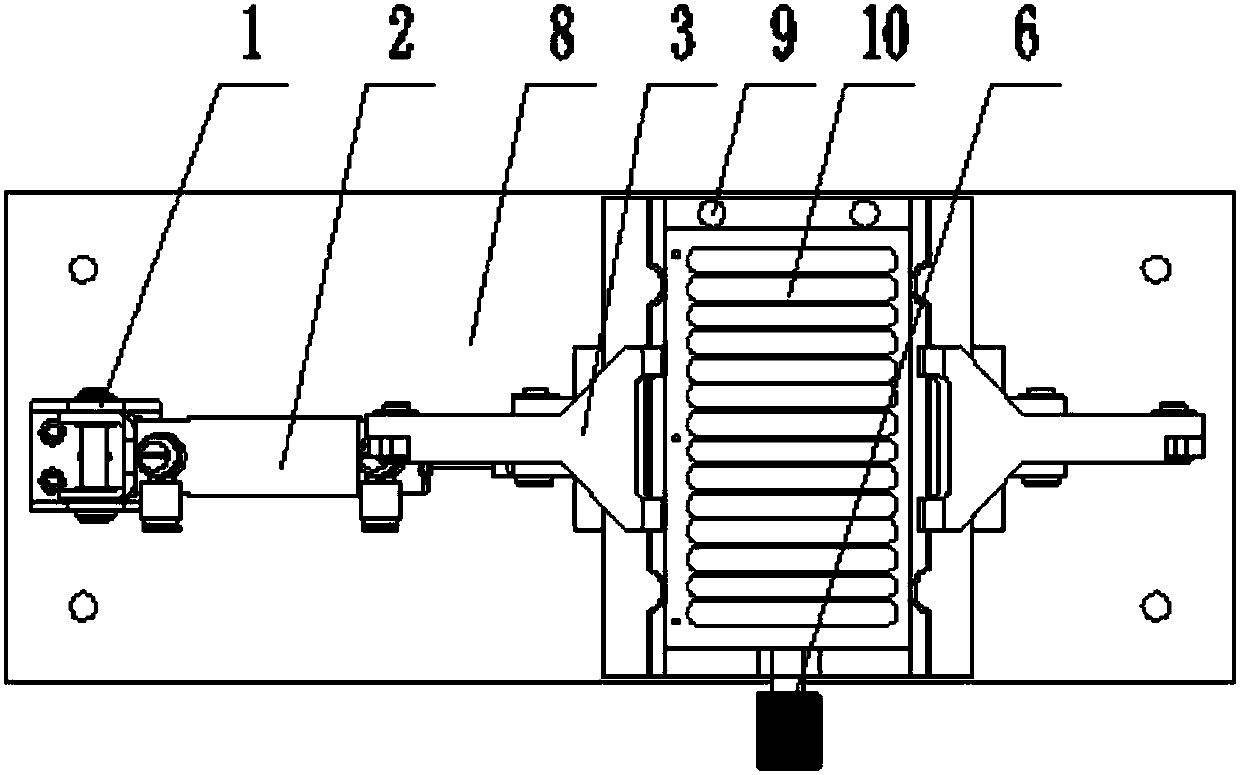

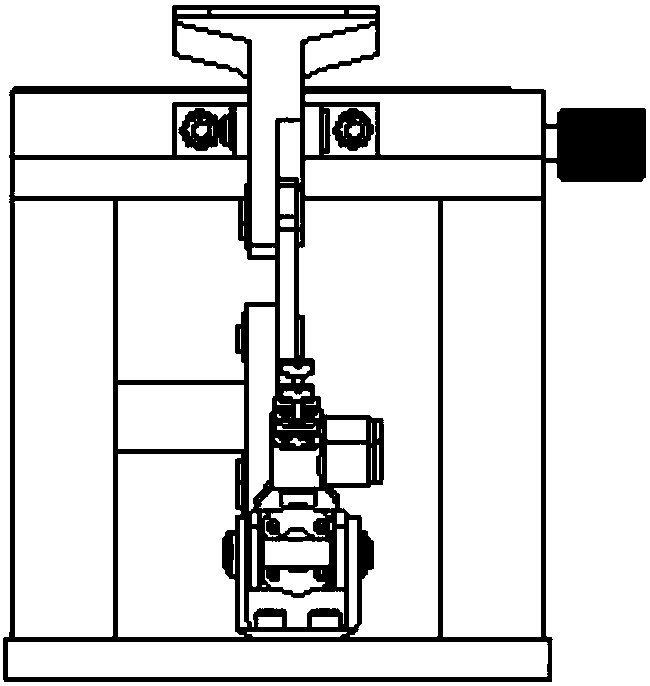

[0018] A special clamping device for double-sided pressing of plate workpieces, including a base plate 8, a support frame 11, a cylinder 2, a turntable 5, a connecting rod 7 and a pressure plate 3, and a support frame is installed on one side of the upper surface of the base plate. The front panel and the rear panel are arranged side by side, and the lower ends of the front panel and the rear panel are installed on the bottom panel, and the upper ends of the front panel and the rear panel are installed on the top panel. Make the workpiece installation area, install the vertical positioning column 9 on the rear end of the upper surface of the top plate, and the positioning column is usually two symmetrically arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com