Multifunctional efficient grain moisture online detection device

A technology of grain moisture and detection device, applied in the field of agricultural machinery, can solve the problems of the influence of measurement results, uneven rolling, insufficient grain harvesting, etc., and achieve the effect of improving the accuracy of moisture measurement, accurate moisture measurement, and solving sampling mixed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

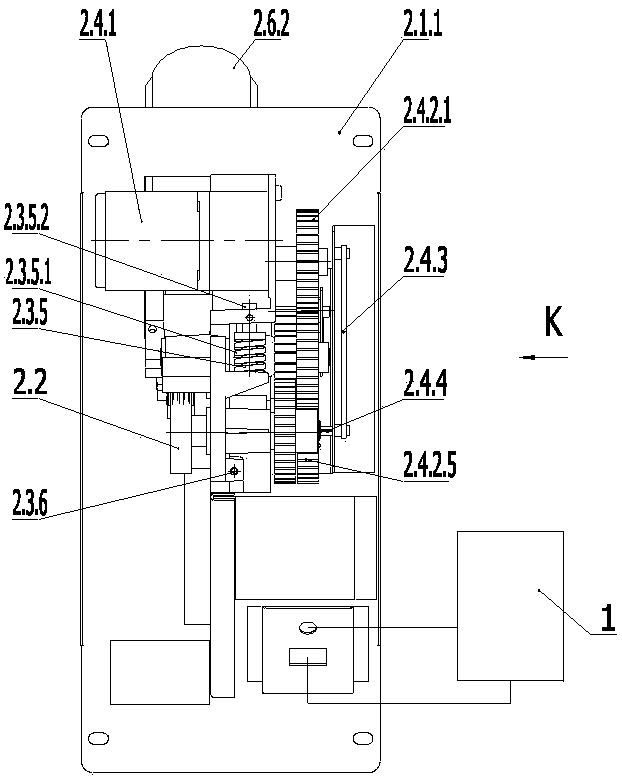

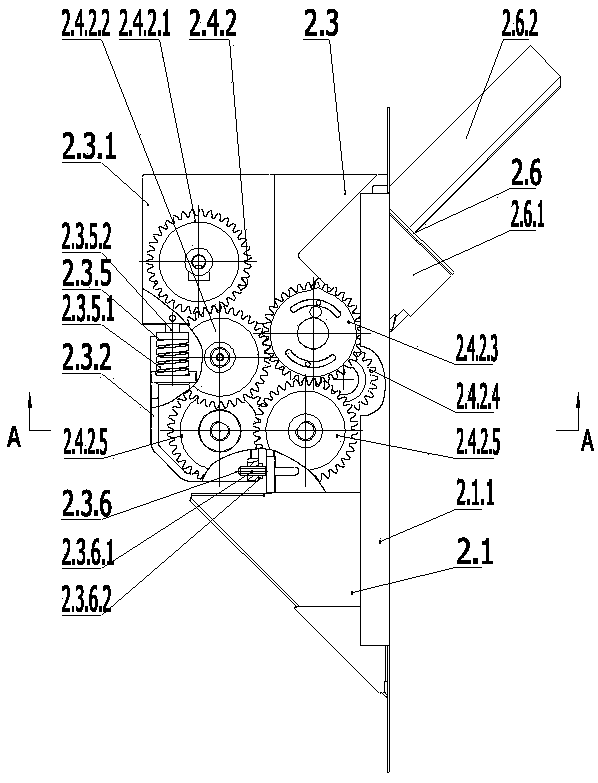

[0022]The multifunctional high-efficiency grain moisture online detection device shown in the attached figure is installed on the side wall of the elevator of the grain dryer, and includes a control system 1 and a measurement system 2; the measurement system 2 includes a housing 2.1, a measurement mechanism 2.2, and a base assembly 2.3 , drive mechanism 2.4, grain deflector 2.5, collection and feeding device 2.6; housing 2.1 includes base plate 2.1.1, outer cover 2.1.2; base plate 2.1.1 is provided with a rectangular square hole on the upper side; base assembly 2.3 is erected and fixed on Bottom plate 2.1.1 inner side wall, including fixed base 2.3.1, movable base 2.3.2, connecting shaft 2.3.3, shaft sleeve 2.3.4, elastic adjustment mechanism 2.3.5, screw adjustment mechanism 2.3.6; movable base 2.3. 2 is connected with the fixed base 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com