Speed change device with coaxial connecting rod rolling disc

A speed change device and rolling disc technology, which is applied to the transmission device, transmission device parts, friction transmission device, etc., can solve the problems affecting the actuation of the speed change device and the operation of the shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

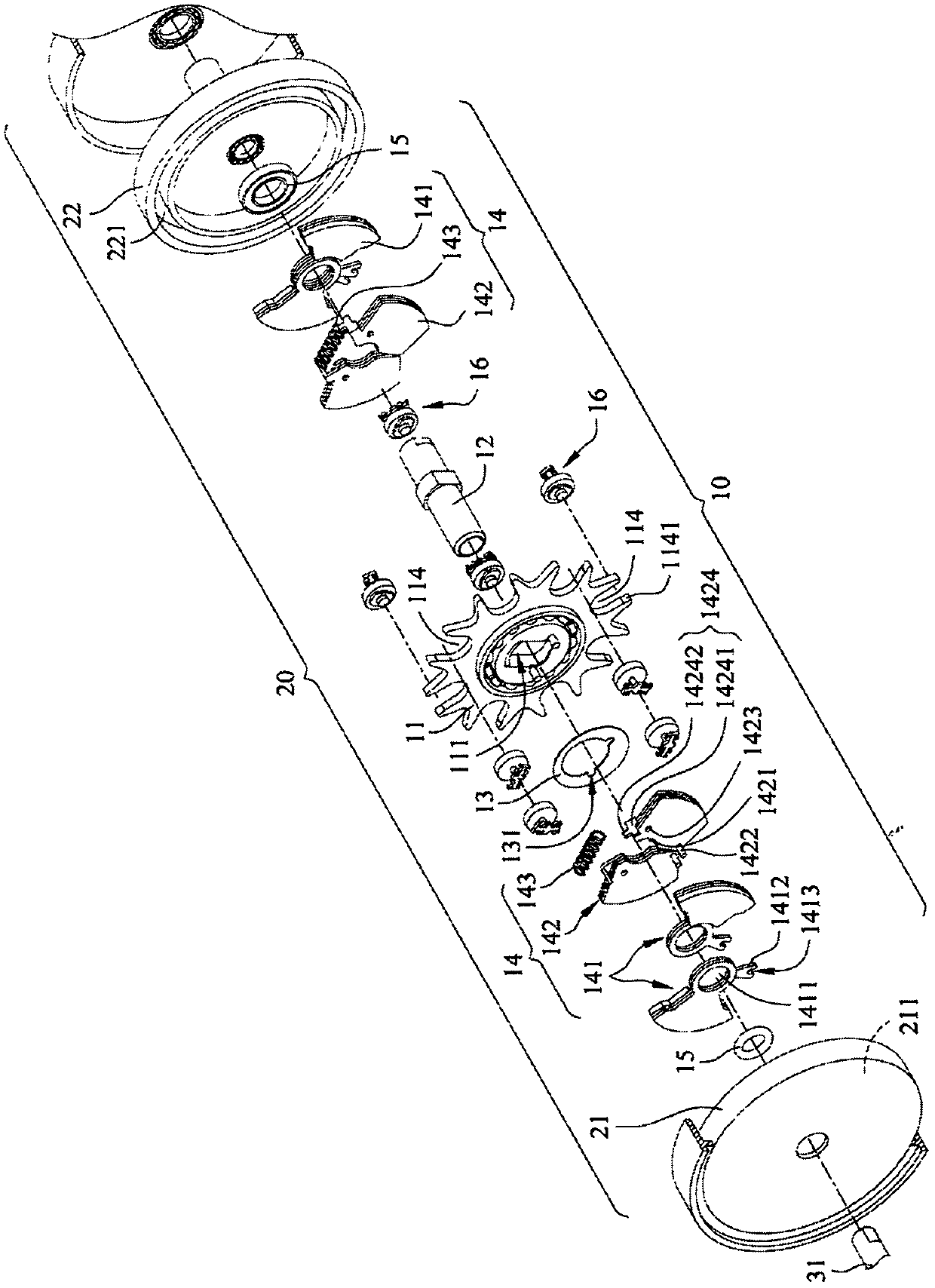

[0052] In order to facilitate your examiner to have a further understanding and understanding of the technical means and operation process of the present invention, here is an example with accompanying drawings, and the detailed description is as follows:

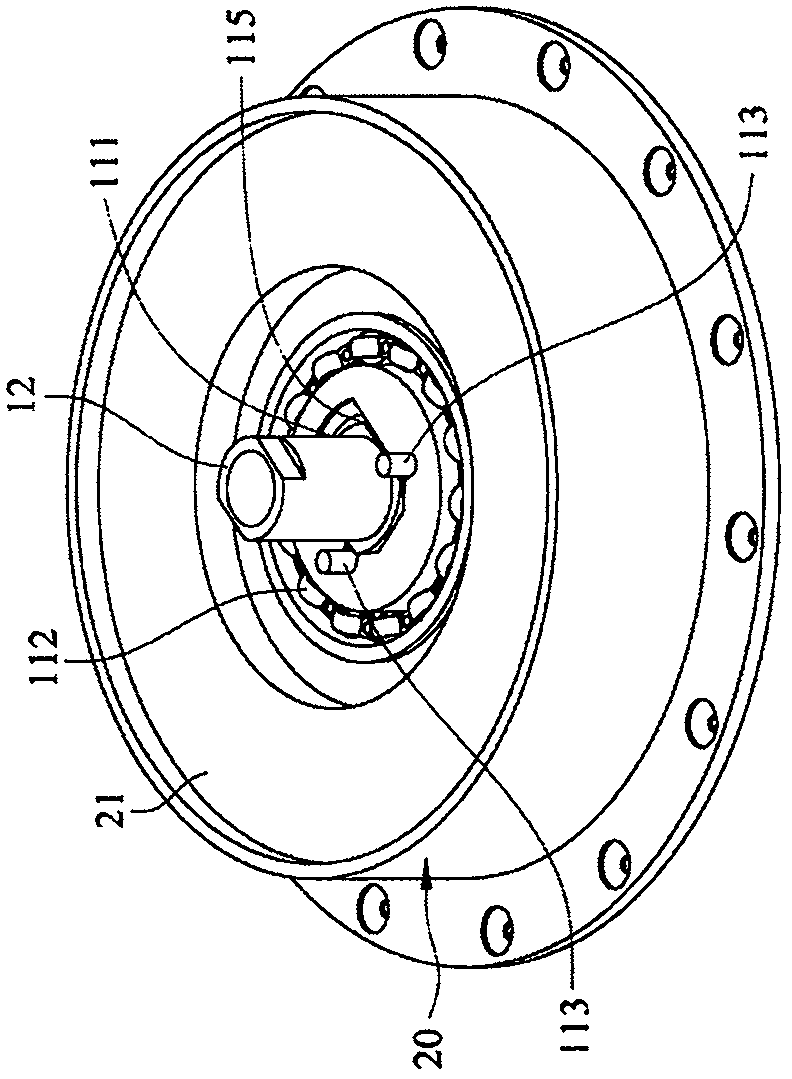

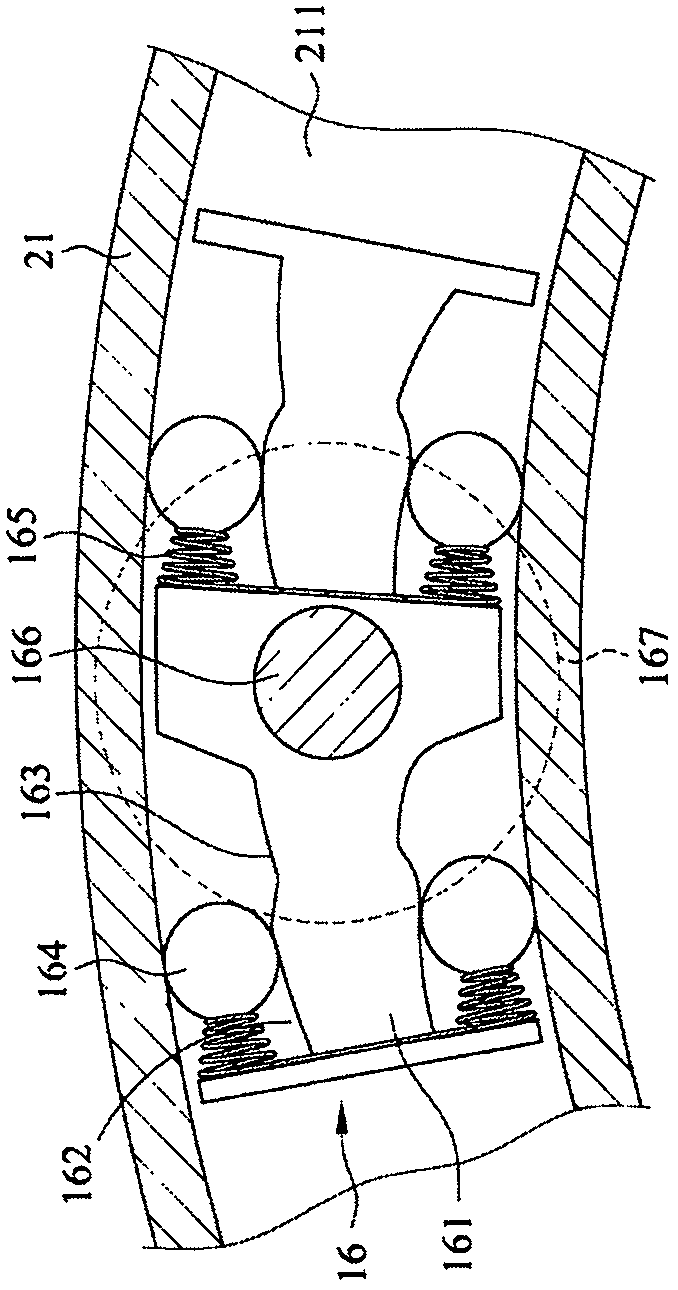

[0053] see figure 1 As shown, the present invention provides a speed change device for coaxial connecting rod rollers, which includes a body 10 and a transmission housing 20, the body 10 is arranged in the transmission housing 20, wherein one side of the transmission housing 20 has A hollow annular first clutch disc 21, the edge ring of the first clutch disc 21 is provided with a recessed sliding groove 211, the transmission case 20 has a second clutch disc 22 on the opposite side of the first clutch 21, and A sliding groove 221 is arranged around the edge of the second clutch groove 22 and opposite to the first clutch groove 21. The center of the second clutch groove 22 has a through shaft hole 222, and the shaft hole 222...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com