An electrolytic copper powder scraper device

A technology of electrolytic copper powder and scraper, applied in the direction of electrolytic components, electrolytic process, etc., can solve the problems of inability to guarantee the quality of scraping, time-consuming and laborious, etc., and achieve the effect of improving work efficiency and quality, reducing manual operation, and simple operation

Active Publication Date: 2019-02-19

铜陵市业永兴工贸有限责任公司

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to solve the shortcomings in the prior art, such as: the traditional method of scraping copper powder is manual operation, which is time-consuming and laborious, and cannot guarantee the quality of scraping, and proposes an electrolytic Copper powder scraper device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

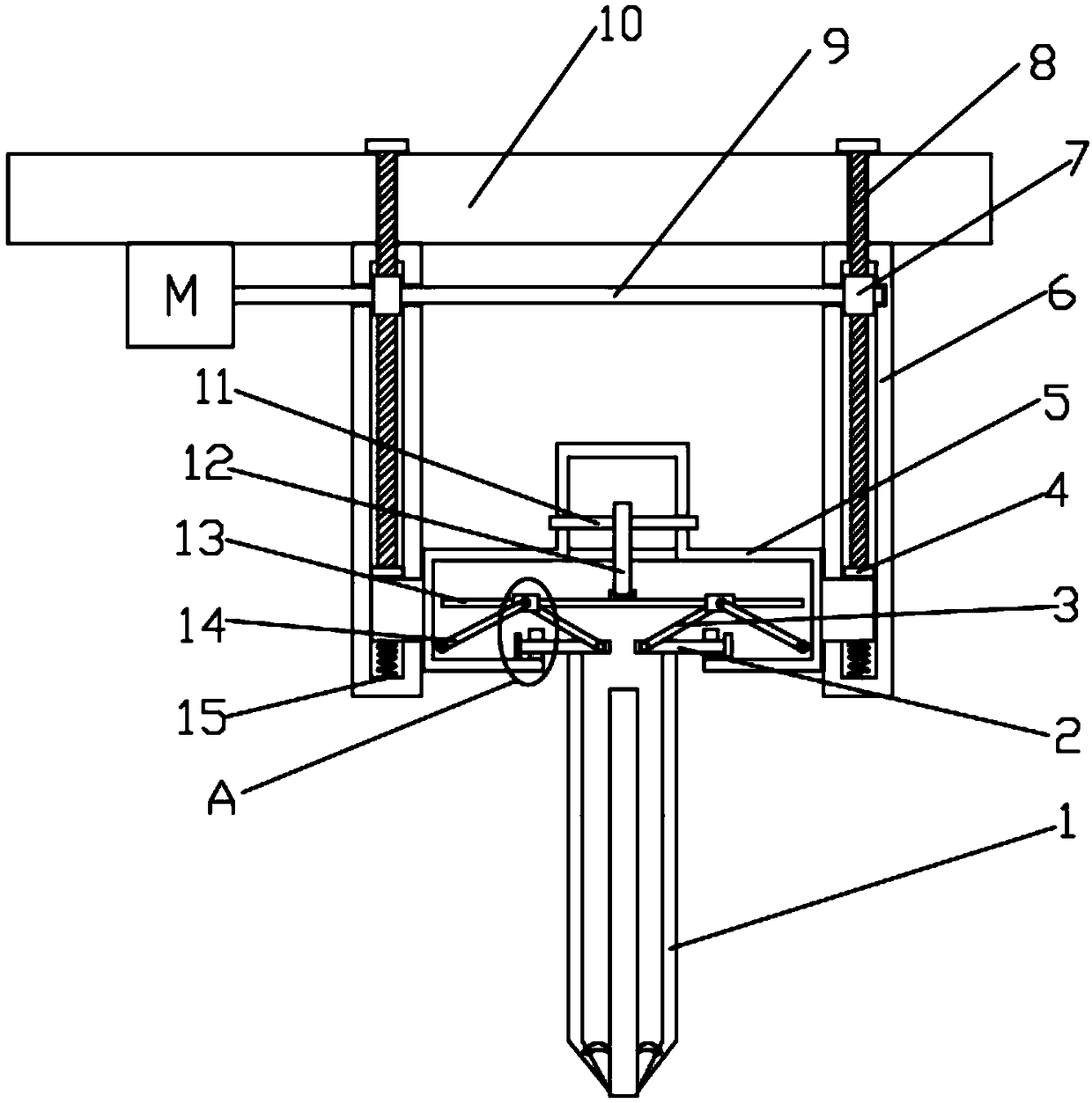

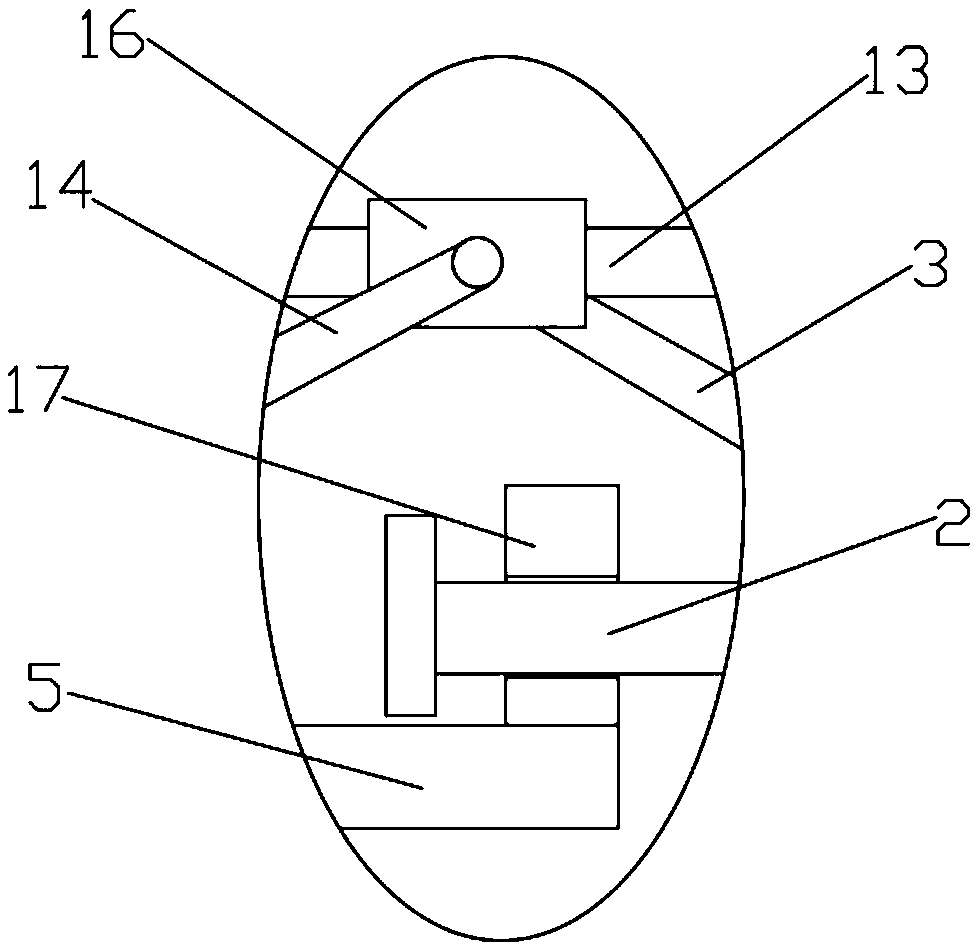

The invention discloses an electrolytic copper powder scraper blade device, which comprises a top seat and a pair of scraper blades. The pair of scraper blades is arranged under the top seat; slidingmechanisms are symmetrically arranged on one side of the top seat; each sliding mechanism comprises a sideway and a worm rod; a sliding slot is formed in each slideway; one end of each worm rod is inserted onto each sliding slot; the other end of each worm rod penetrates through the top seat; connecting blocks are arranged on two ends of each worm rod; a motor is arranged on the top seat; a rotaryshaft is rotatably connected to a drive end of the motor; two worm wheels are connected onto the rotary shaft in a sleeving way and are respectively arranged on one sides of the worm rods. The electrolytic copper powder scraper blade device provided by the invention is simple to operate; through the interaction of the top seat, the scraper blades, the sliding mechanisms and a fixing device, copper powder can be efficiently scraped, so that the manual operation is greatly reduced, the work efficiency and the work quality are improved, and the influence of uncontrollable factors brought by manual operation is avoided; the electrolytic copper powder scraper blade device is provided for users.

Description

technical field [0001] The invention relates to the technical field of copper melting auxiliary equipment, in particular to an electrolytic copper powder scraper device. Background technique [0002] In the prior art, copper plates are used as anodes to electrolyze refined copper. During the electrolytic refining process, the decomposed copper powder will adhere to the surface of the copper electrode, hindering the electrolysis process of the copper electrode. The copper powder on the surface needs to be removed. Scraping, in the existing technology, scraping off the copper powder is still achieved by manual operation. It is necessary to use a shovel to manually scrape the powder on both sides of the copper electrode one by one or even multiple times. This operation method will inevitably make scraping The process of powdering is very slow, relying solely on manual operation is inefficient, and there will be uncontrollable factors that lead to insufficient powder scraping, w...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C25C7/08C25C5/02

CPCC25C5/02C25C7/08

Inventor 胡明海

Owner 铜陵市业永兴工贸有限责任公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com