Electrolysis device for preparing high purity titanium

An electrolysis equipment and high-purity technology, applied in the direction of electrolysis components, electrolysis process, etc., can solve the problems of rising cost of molten salt electrolysis, low utilization rate of electrolyte solution, etc., and achieve the effect of maintaining stability, avoiding changes, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention is described further as follows:

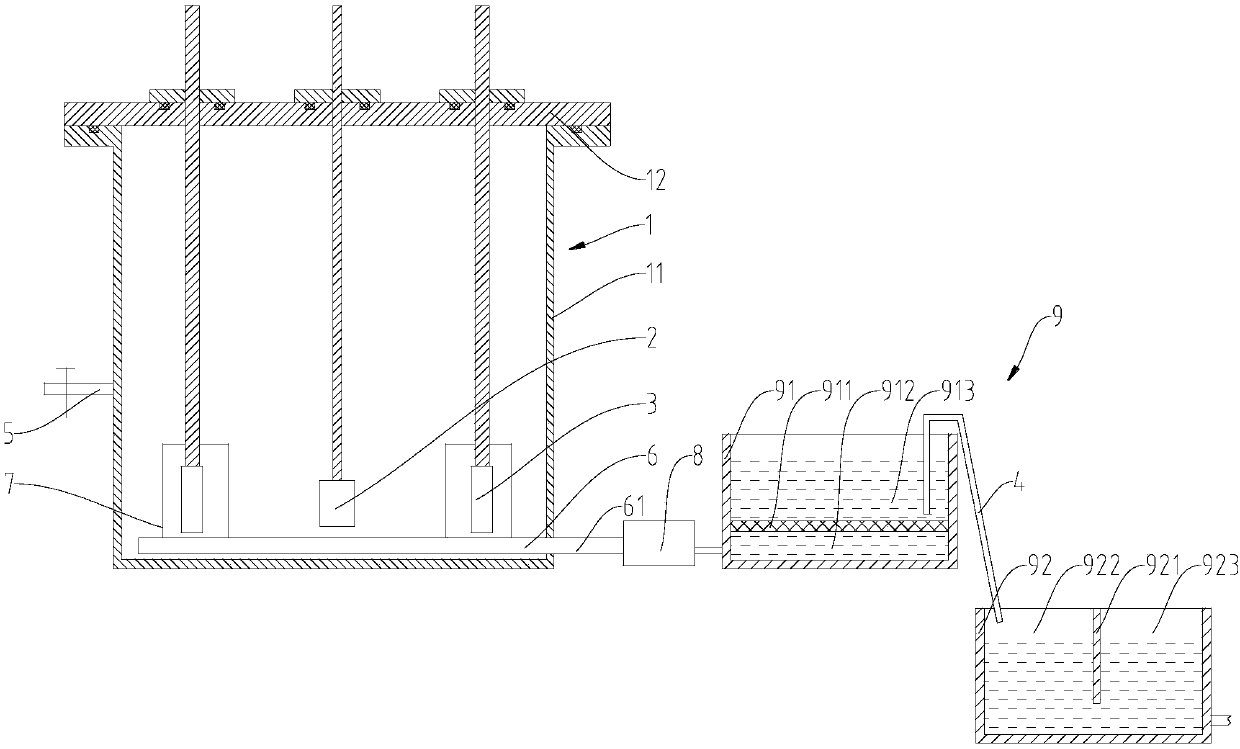

[0016] The electrolysis equipment for preparing high-purity titanium includes an electrolysis reactor 1, a cathode plate 2 and a titanium-coated anode plate 3 for electrolysis, and the electrolysis reactor 1 is a closed container formed by sealing a reaction body 11 and a reaction cover 12;

[0017] An electrolyte introduction pipe 5 communicating with the cavity of the electrolytic reactor 1 is provided outside the electrolytic reactor 1;

[0018] The cathode plate 2 and the titanium-coated anode plate 3 are located in the electrolytic reactor 1, and a guide tube 6 is arranged in the electrolytic reactor 1. The guide tube 6 is located below the titanium-coated anode plate 3, and one end thereof extends into the electrolytic reactor 1. An anolyte outlet 61 is arranged outside the reactor 1; an anode diaphragm bag 7 is set outside the titanium-coated ano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com