Low temperature curing silicone ink, preparation method and application

A silicone ink, low temperature technology, applied in the direction of ink, application, household utensils, etc., can solve the problems of narrow application materials, high curing temperature, etc., and achieve the effect of increasing adhesion, low curing temperature and excellent wrapping property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Another aspect of the present invention provides a method for preparing the above-mentioned low-temperature curing silicone ink, comprising the following steps:

[0047] Add methyl vinyl silicone resin, methyl phenyl silicone resin, and hydrogen-containing silicone oil into the dispersion container, stir at 600-1000 rpm for 5-10 minutes, then add white carbon black and organic pigments, and stir at 1200 Stir at ~2000 rpm for 20-30 minutes, then add the inhibitor and siloxane coupling agent, and stir at 400-800 rpm for 5-10 minutes to obtain a mixture.

[0048] The mixture was ground to a fineness <10um.

[0049] The metal catalyst is added to the ground mixture, and the low-temperature curing silicone ink is obtained after stirring at 600-800 rpm for 5-6 minutes.

[0050] White carbon black and organic pigments are slowly added while stirring. A disperser can be used to stir and disperse. Under the above conditions, the white carbon black, organic pigments, and organi...

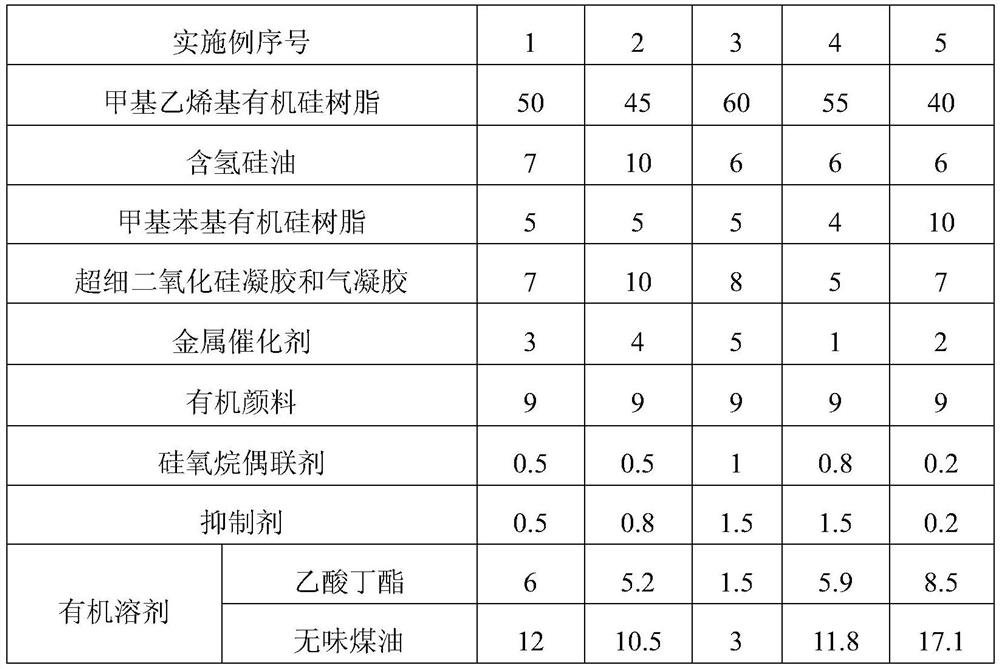

Embodiment 1~5

[0063] The preparation method of embodiment 1~5 silica gel ink is as follows:

[0064] (1) Add methyl vinyl silicone resin, methyl phenyl silicone resin, and hydrogen-containing silicone oil into the dispersion container, stir at 600-1000 rpm for 5-10 minutes, then slowly add white carbon black while dispersing , and organic dyes, stirring at 1200-2000 rpm for 20-30 minutes, finally adding inhibitor and siloxane coupling agent, stirring at 400-800 rpm for 5-10 minutes.

[0065] (2) Grind the mixture 3 to 4 times with a three-roll machine to ensure that the fineness of the ink is less than 10um.

[0066] (3) Pre-mixing: add a metal catalyst to the above mixture, and stir at 600-800 rpm for 5-6 minutes to obtain the ink product.

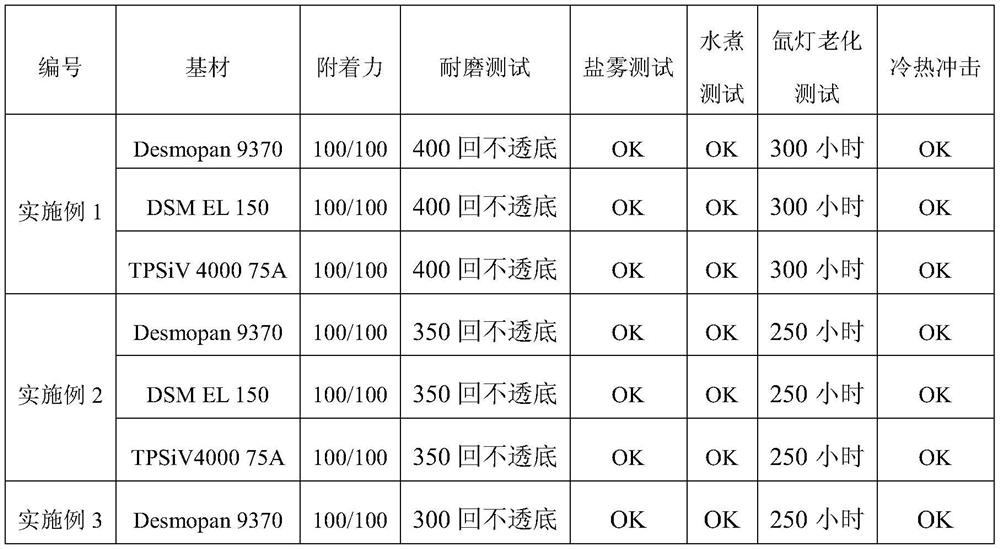

[0067] Coating and curing method of the silicone coating in Examples 1-5: screen-print the silicone ink prepared in Examples 1-5 on the LSR substrate, the coating film thickness is 8 microns, and bake in an oven at 90°C for 20 minutes.

[0068] The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com