A kind of ammonia absorption deodorization breathable film for diapers

A technology of breathable film and diapers, which is applied in the field of polymer materials, can solve the problem that the breathable film cannot be adsorbed, and achieve the effects of light weight, strong air permeability, and high air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

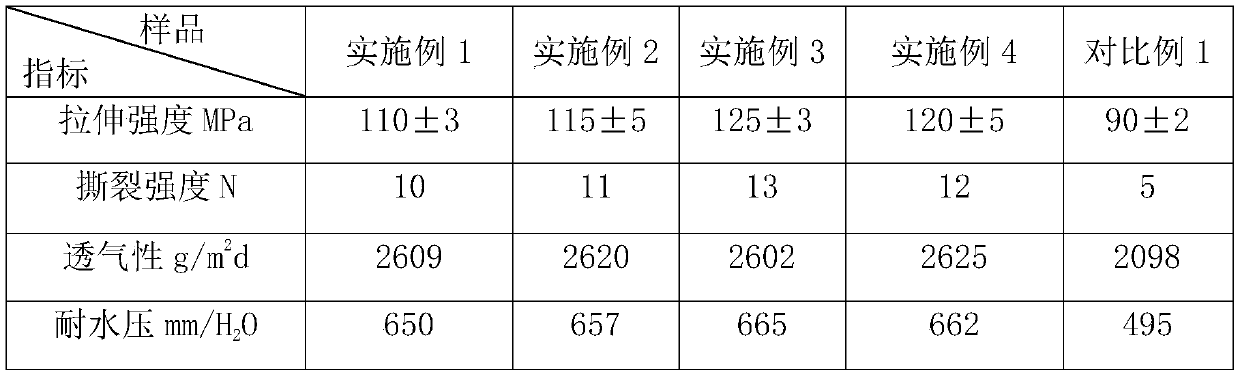

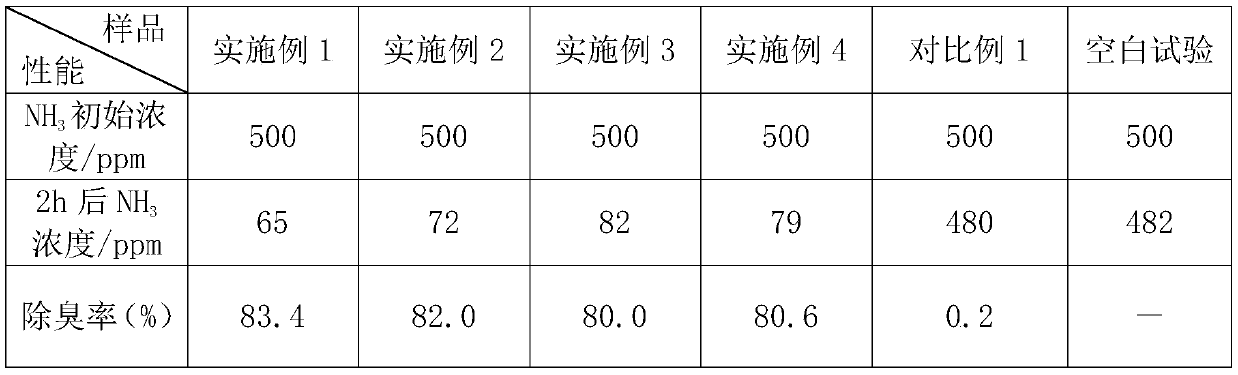

Examples

Embodiment 1

[0032] The porous adsorption and air-permeable membrane of this embodiment is made of the following raw materials in parts by weight: 30 parts of low-density polyethylene, 30 parts of polypropylene, 15 parts of silica-alumina zeolite molecular sieve, 4 parts of polyurethane elastomer, and vinyl-containing silane coupling agent 1 part, 1 part of molecular saturated wax lubricant, 0.1 part of styrene-acrylonitrile-glycidyl methacrylate. Among them, the particle size of silica-alumina zeolite molecular sieve is 0.3-0.5um, and the specific surface area is 400m 2 / g.

[0033] The preparation method of the porous adsorption gas-permeable membrane of this embodiment comprises the following steps:

[0034] S1. Perform acidification pretreatment on the silica-alumina zeolite molecular sieve. Put the silica-alumina zeolite molecular sieve into the citric acid microcapsule solution, so that the concentration of the silica-alumina zeolite molecular sieve is 5%-20%, then ultrasonically t...

Embodiment 2

[0043] The porous adsorption air-permeable membrane of this embodiment is made of the following raw materials in parts by weight: 60 parts of high-density polyethylene, 65 parts of polypropylene, 30 parts of silicon phosphorus aluminum zeolite molecular sieve, 10 parts of polybutene elastomer, epoxy group-containing 5 parts of silane coupling agent, 3 parts of zinc stearate, 3 parts of fatty acid soap, 3 parts of oxidized polyethylene wax. Among them, the particle size of silica-alumina zeolite molecular sieve is 0.3-0.5um, and the specific surface area is 480m 2 / g.

[0044] The preparation method of the porous adsorption gas-permeable membrane of this embodiment comprises the following steps:

[0045] S1. Put the silicon phosphorus aluminum zeolite molecular sieve into the citric acid microcapsule solution so that the concentration of the silicon phosphorus aluminum zeolite molecular sieve is 5%-20%. Dry to constant weight.

[0046] S2. Weigh each raw material in parts by...

Embodiment 3

[0054] The porous adsorption air-permeable membrane of this embodiment is made of the following raw materials in parts by weight: 45 parts of linear low density polyethylene, 50 parts of polypropylene, 24 parts of silica gel powder, 7 parts of polyurethane elastomer, 3 parts of resin acid, calcium stearate 2 parts, 2 parts of styrene-acrylonitrile-glycidyl methacrylate, 1 part of EVA wax. Among them, the particle size of silica gel powder is 0.3-0.5um, and the specific surface area is 400m 2 / g. The resin acid in this embodiment is a resin acid commonly used in plastic processing technology, industrial grade, and commercially available.

[0055] The preparation method of the porous adsorption gas-permeable membrane of this embodiment comprises the following steps:

[0056] S1. Put the silica gel powder into the citric acid microcapsule solution so that the concentration of the silica gel powder is 10%-20%, then ultrasonically treat for 4-6 hours, then filter with suction, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com