an anaerobic reactor

An anaerobic reactor and reaction zone technology, applied in the field of anaerobic reactors, can solve problems such as insufficient construction space, large energy consumption, and limited diameter, and achieve the effects of improving volume utilization, uniform water distribution, and avoiding local acidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

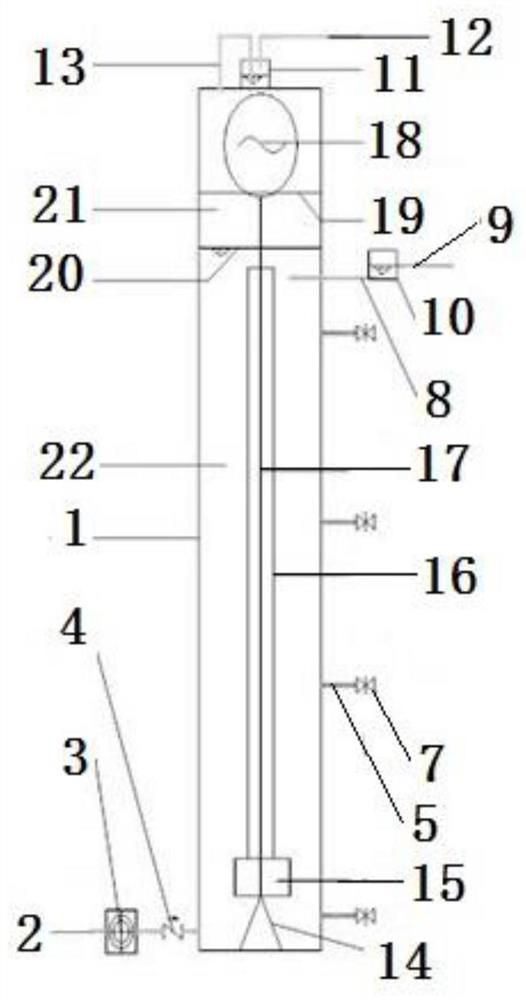

[0013]The main structure of the anaerobic reactor involved in this embodiment includes a tank body 1, an inlet pipe 2, an inlet pump 3, a check valve 4, a mud discharge horizontal pipe 5, a valve 7, an outlet pipe 8, a drain pipe 9, a positioning water seal 10. Constant pressure water seal 11, air outlet pipe 12, air pipe 13, bottom support 14, diffusion pump 15, water suction pipe 16, bearing 17, motor 18, top support 19, liquid level 20, air chamber 21 and reaction zone 22; A water inlet pipe 2 of a tubular structure is arranged on the outside of the bottom of the tank body 1 of the hollow cylindrical structure, and a water inlet pump 3 of a horizontal structure is arranged on the end of the water inlet pipe 2 far away from the tank body 1, and the water inlet pipe 2 close to the tank body 1 One end is provided with a check valve 4, and the outside of the middle and lower part of the tank body 1 is provided with 4-6 segments of mud discharge horizontal pipes 5 in a tubular st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com