Carrying robot and working method thereof

A technology for handling robots and walking mechanisms. It is applied in the direction of lifting devices, etc. It can solve problems such as high salary costs, inability to meet production needs, and the risk of staff fatigue and mistakes, and achieve the effect of reducing the overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

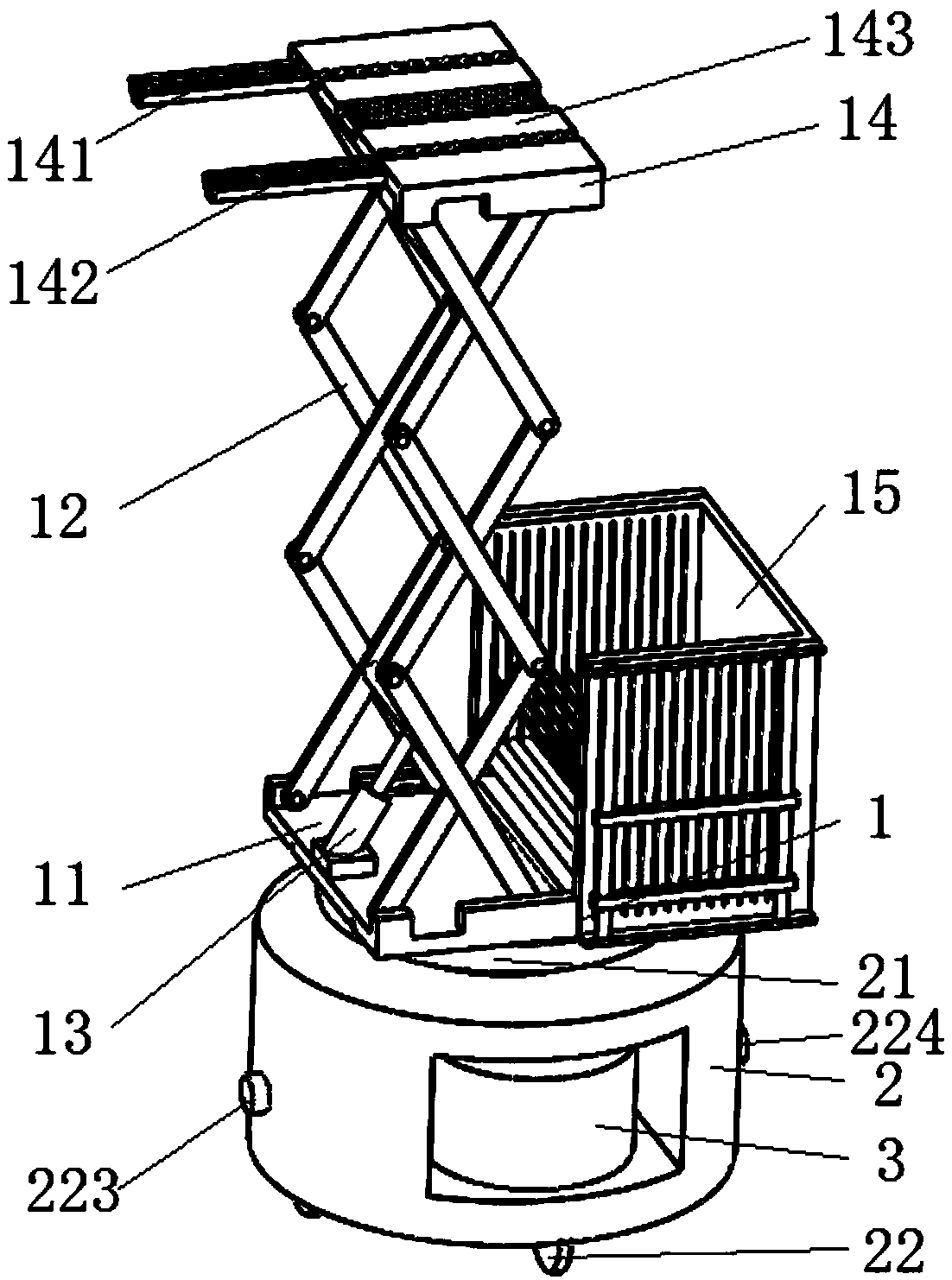

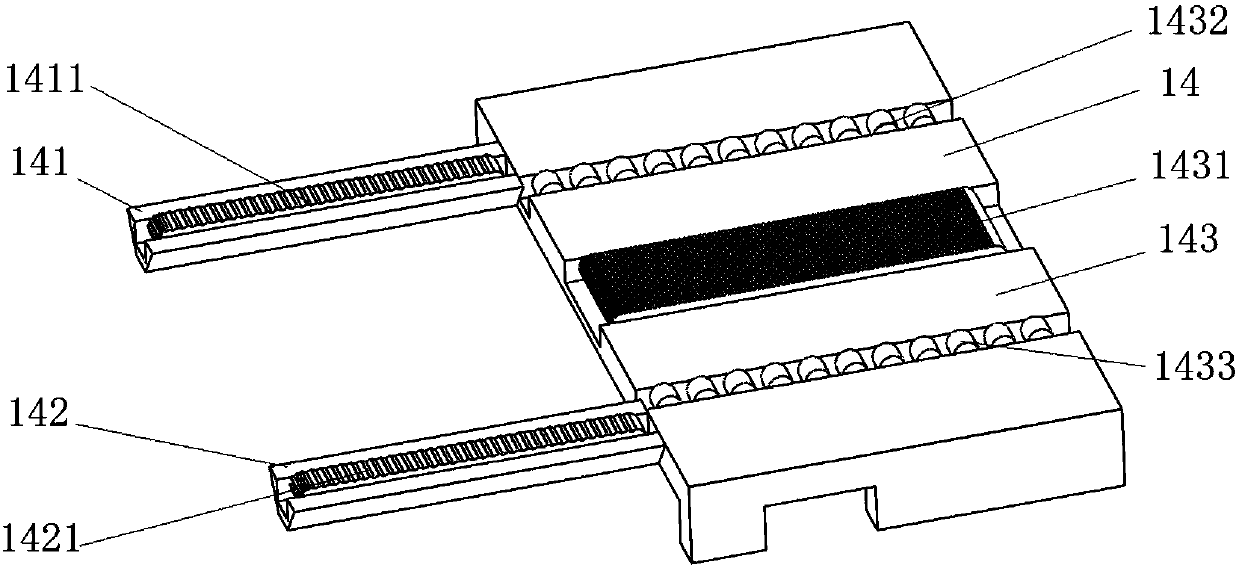

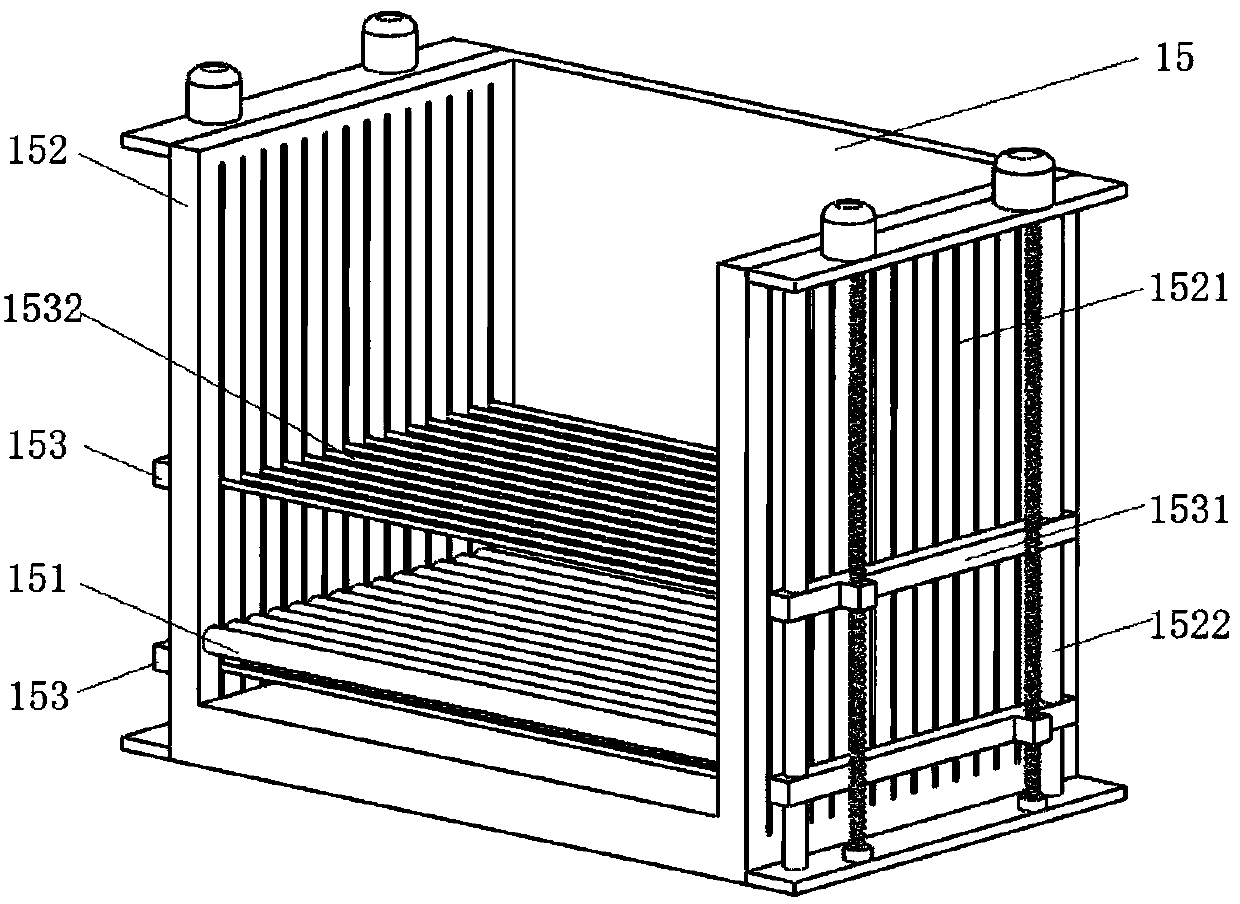

[0018] A kind of handling robot as shown in the accompanying drawing, comprises loading system 1, traveling system 2 and control system 3; Said loading system 1 is installed on traveling system 2; Said control system 3 is located inside traveling system 2; Said control The system 3 is respectively connected to the loading system 1 and the travel system 2; the loading system 1 includes a base 11, a scissor lift frame 12, a hydraulic cylinder 13, a fork 14 and a warehouse 15; the travel system 2 includes a rotating platform 21 and the running mechanism 22; the base 11 is connected with the rotating platform 21 and can rotate together with the rotating platform 21, so that the loading system 1 can flexibly switch between the shelves on the left and right sides, reducing the adjustment time of the running mechanism 22; The scissor lift frame 12, the hydraulic cylinder 13 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com