Downproof, waterproof and anti-microbial flexible fabric

An anti-drilling and flexible technology, applied in the field of garment processing, can solve the problems of poor waterproofness, poor quick-drying effect, lack of antibacterial effect, etc., and achieve the effect of good air permeability and good waterproofness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

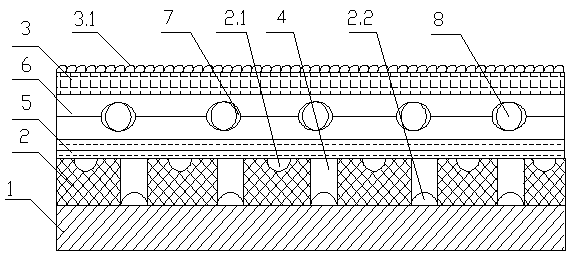

[0010] Such as figure 1 As shown, a kind of anti-drilling velvet waterproof and antibacterial flexible fabric in the present embodiment mainly includes an inner layer 1 made of chemical fibers, a waterproof layer 2 and a surface layer 3 made of natural fibers. Ventilation holes 4 are provided, and a waterproof breathable film 5 is arranged between the waterproof layer 2 and the surface layer 3. The waterproof breathable film 5 has good water resistance, and the breathable holes 4 provided on the waterproof layer 2 make it have Good air permeability, an antibacterial layer 6 is arranged between the waterproof gas-permeable membrane 5 and the surface layer 3, and the antibacterial layer 6 includes an inner layer and an outer layer structure on both sides, and the inner layer and the outer layer are staggered and interwoven at intervals. togethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com