Rubber pulverizer

A pulverizer and rubber technology, which is applied in the field of rubber processing, can solve the problems of rubber melting, adhesion, and affecting service life, and achieve the effect of preventing screen blockage, preventing excessive temperature, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

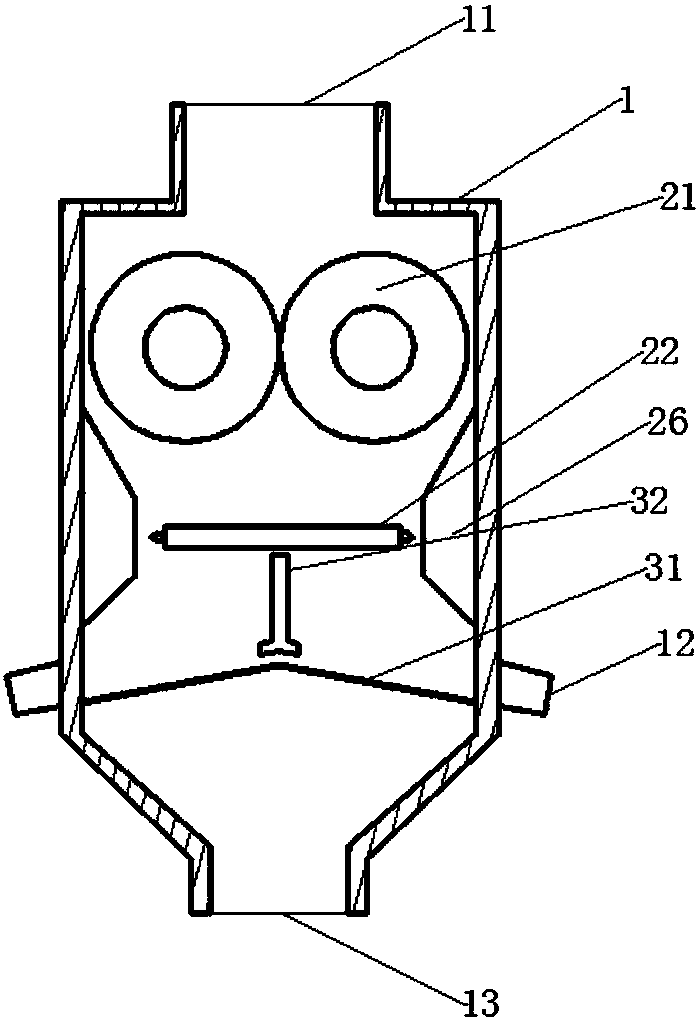

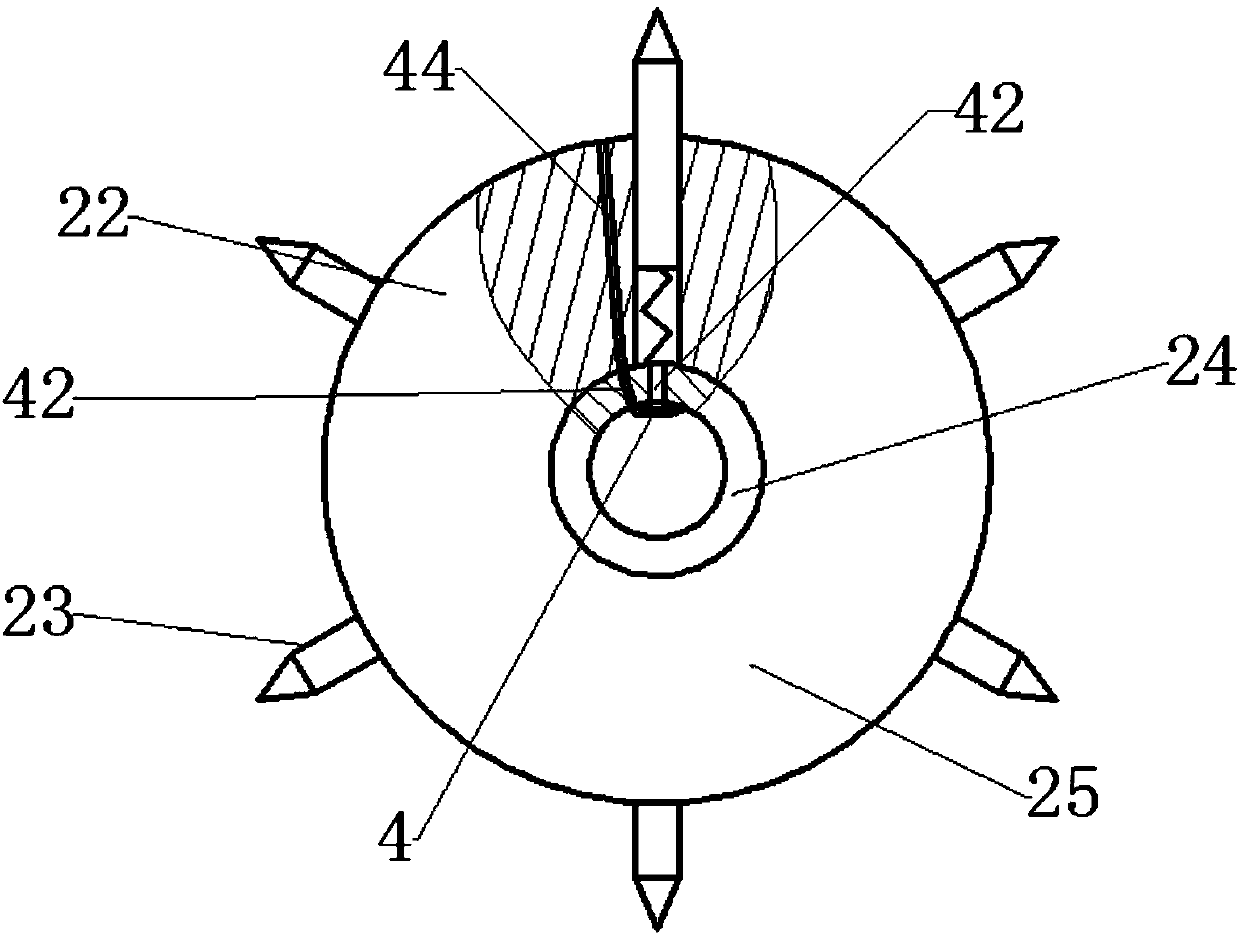

[0026] like figure 1 , image 3 and Figure 4 As shown, a rubber pulverizer includes a housing 1, a cutting device, a screening device, and a cooling device. The upper part of the housing 1 is a feed opening 11 , the lower side of the housing 1 is provided with a discharge opening 12 , and the bottom of the housing 1 is a discharge opening 13 . The cutting device is inside the housing 1, including two rollers and a crushing wheel 22. Multiple sets of cutter heads are installed on the rollers, and the cutter heads on the two rollers are interlaced to form a shearing mechanism; the crushing wheel 22 is installed horizontally Below the roller 21, a guide block 26 is also installed on the outer casing 1 of the crushing wheel 22. The crushing wheel 22 includes a crushing knife 23, a first sleeve 24 and a second sleeve 25, and the first sleeve 24 circumferentially A spring is installed, and one end of the spring is connected to the outer circular side wall of the first sleeve 24,...

Embodiment 2

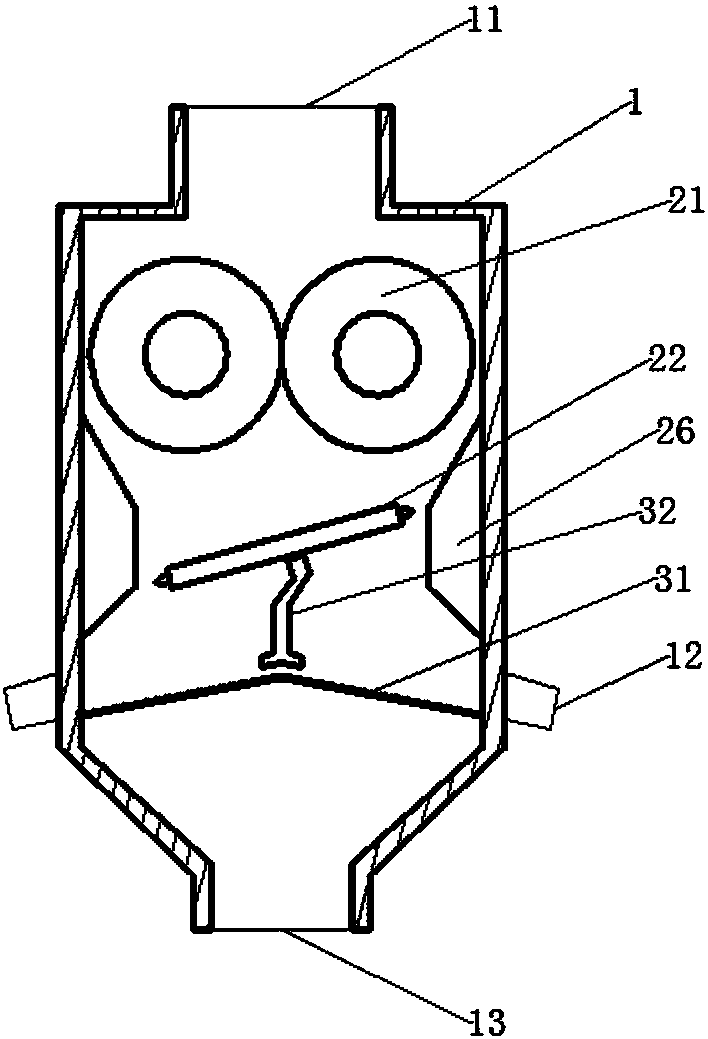

[0029] like figure 2 As shown, a rubber pulverizer differs from the first embodiment in that the pulverizing wheel 22 has an inclination angle with the horizontal direction. The pulverizing wheel 22 rotates on the inclined surface, and the pulverizing knife 23 will pass through the position of the lowest point and the highest point during the rotation process. When the pulverizing knife 23 is at the lowest point, since the gravitational force and the centrifugal force on the pulverizing knife 23 are on the same side, The force of the spring is relatively large, and the protruding length of the pulverizing knife 23 is relatively long. When the pulverizing knife 23 is at the highest point, the gravity of the pulverizing knife 23 is not on the same side as the centrifugal force, and the force of the spring is small, so the protruding length of the pulverizing knife 23 is relatively short. , The crushing knife 23 can also expand and contract in the first through hole when not tou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com