Kitchen waste treatment system and technology

A food waste and treatment system technology, which is applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of long processing time, poor surrounding environment, easy breeding of mosquitoes, etc., and achieve equipment mechanization and The effect of high degree of automation, killing pathogenic bacteria and parasites, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing:

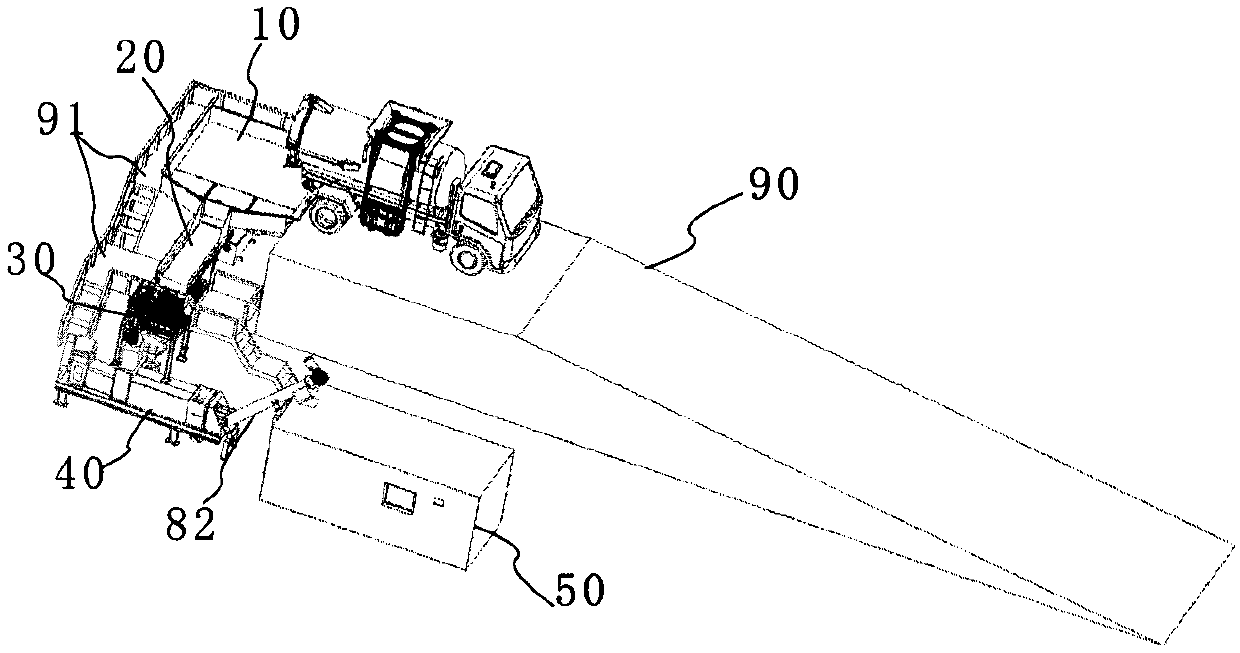

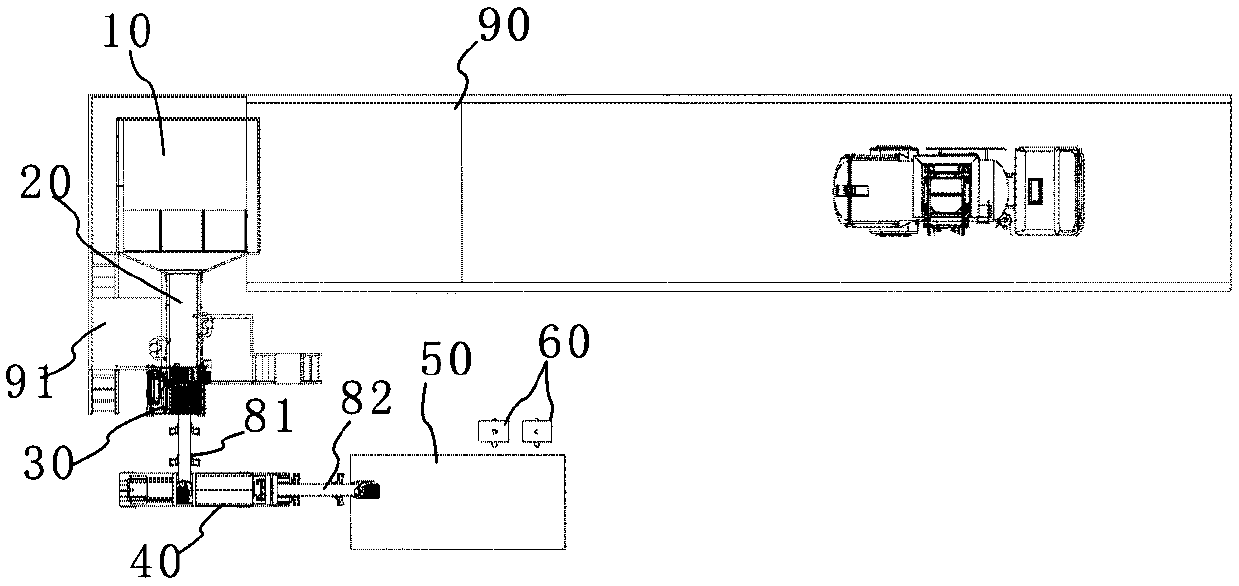

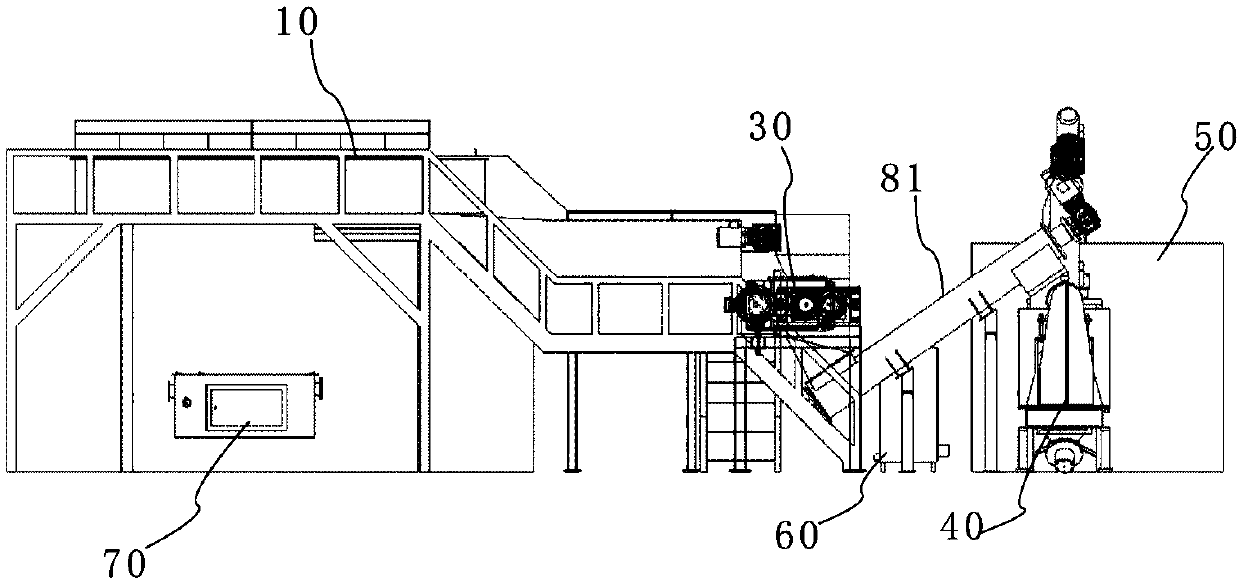

[0037] Such as Figure 1-11 As shown, this embodiment provides a food waste treatment system, including a collection hopper 10, a sorter 20, a crusher 30, a screw press 40, a degradation box 50, an odor processor 60, an oil-water separator 70, a second A screw conveyor 81 and a second screw conveyor 82.

[0038] In this embodiment, the collection hopper 10 includes a collection frame and a collection bottom plate affixed to the collection frame, there is a space between the collection frame and the collection bottom plate, and the collection bottom plate It is arranged in a slope type, and a movable discharge door 11 is arranged at the bottom of the collecting bottom plate. The collecting bottom plate is composed of two filter plates and a supporting main plate, the two filtering plates are spliced together and are on the same plane as the supporting main plate, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com