Temperature-control safety nipple

A pacifier and safe technology, applied in the field of feeding bottles, can solve the problems of laborious sucking, increased resistance, etc., and achieve the effects of simple production process, reduced resistance, and reduced loss of vitamins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

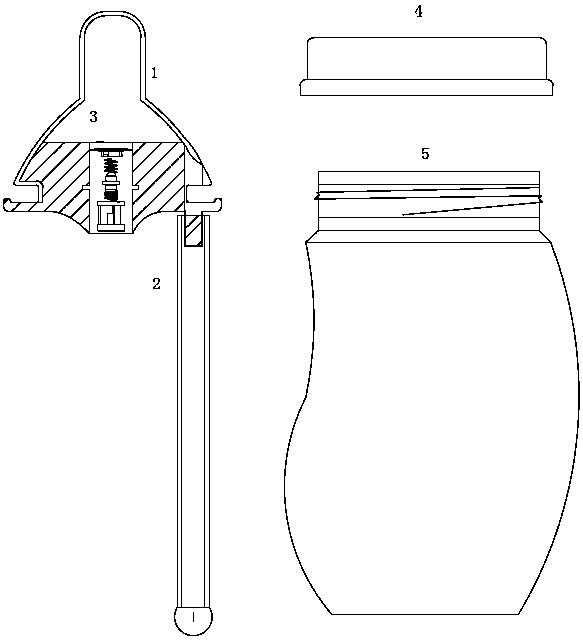

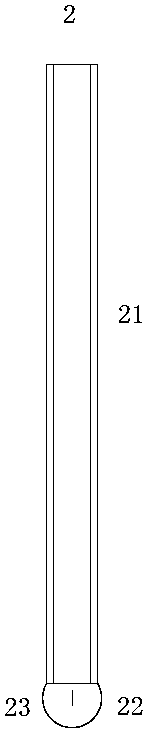

[0058] like figure 2 As shown, a temperature control safety nipple with temperature control function and exhaust function includes: a nipple part 1, an exhaust part 2, and a temperature control part 3 of an upper and lower structure assembled into one body, and the exhaust circuit part is selected from the nipple inlet. The air port 16, the nipple air outlet 13, the exhaust pipe 21, the exhaust ball 22, the exhaust ball cutout 23, the bottle cap 4, and the bottle 5 form an exhaust circuit channel. When the nipple part 1 is in the sucking state, due to When the pressure changes, the venting ball cutout 23 is slightly opened (it should be noted that the venting ball cutout 23 is closed when there is no external force on the nipple part 1), so that the pressure inside the feeding bottle 5 is increased. The pressure on the outside of the feeding bottle 5 is in a very close state, so that the infant can easily suck out the milk, and at the same time, no bubbles will be generated i...

Embodiment 2

[0061] like image 3 As shown in the figure, a temperature control safety nipple with temperature control function and exhaust function includes: a nipple part 1, an exhaust part 2, and a left and right structure temperature control part 4 assembled into one body, and the exhaust circuit part is selected from the nipple inlet. The air port 16, the nipple air outlet 13, the exhaust pipe 21, the exhaust ball 22, the exhaust ball cutout 23, the bottle cap 4, and the bottle 5 form an exhaust circuit channel. When the nipple part 1 is in the sucking state, due to When the pressure changes, the venting ball cutout 23 is slightly opened (it should be noted that the venting ball cutout 23 is closed when there is no external force on the nipple part 1) to make the pressure inside the 5 feeding bottle The pressure on the outside of the feeding bottle 5 is in a very close state, so that the infant can easily suck out the milk, and at the same time, no bubbles will be generated in the mil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com