Grass rolling machine

A grass machine and machine body technology, applied in agricultural machinery and tools, cutting equipment, applications, etc., can solve the problems of unfavorable discharge, affecting the working efficiency of the grass machine, and low kneading and cutting efficiency, so as to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

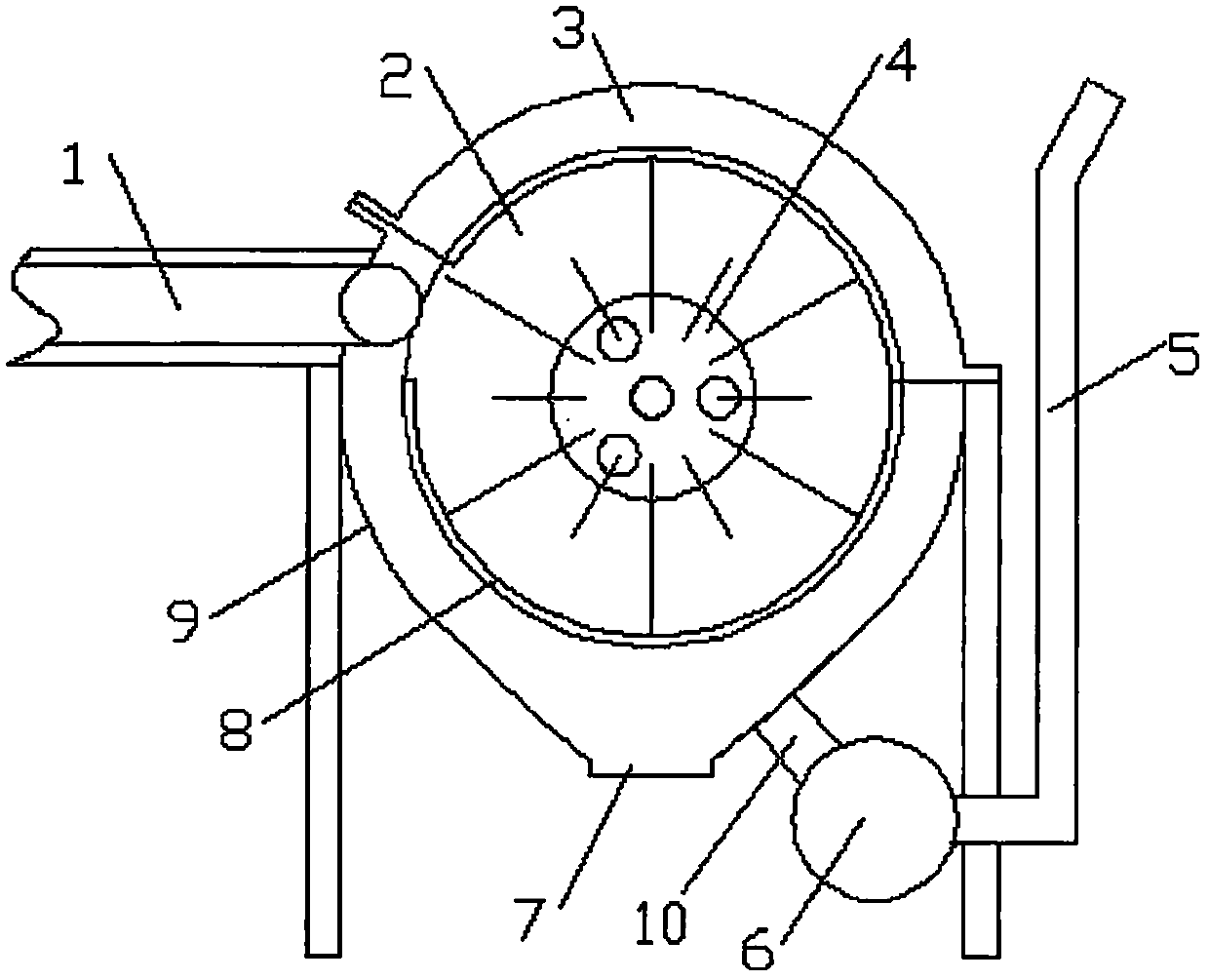

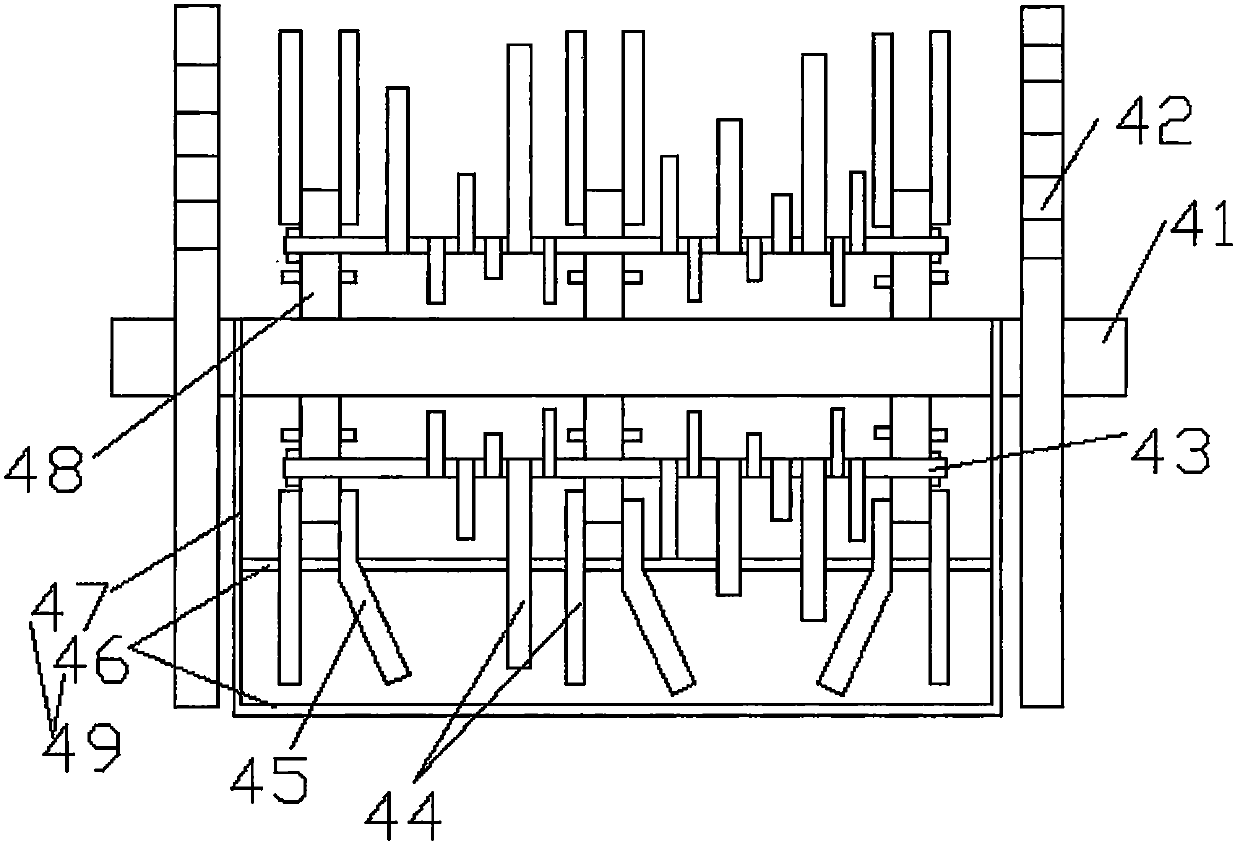

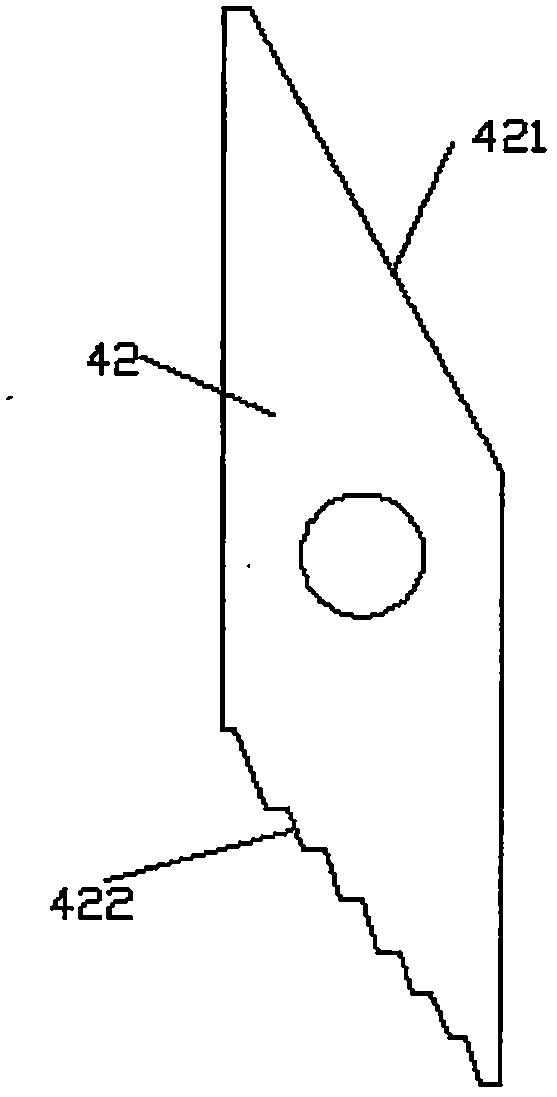

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a grass kneading machine comprises a body 9, the body is provided with a cylindrical kneading grass chamber 2, the side of the kneading grass chamber 2 is connected with an automatic feeding device, and the bottom is provided with a discharge device. The grass cavity is provided with a grass kneading device 4, the grass kneading device 4 includes a rotating main shaft 41, and the rotating main shaft 41 is provided with a scraping rod frame 49, and the two ends of the rotating main shaft 41 are provided with end kneading shafts close to the side of the body 9. Grass blade 42, the rotating main shaft 41 inside the scraper bar frame 49 is connected with a mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com