Environmental-protection curtain-coating finish paint and preparation method thereof

It is an environmental protection technology of curtain coating, applied in the field of coatings, which can solve the problems of easy whitening, large loss, easy to bite the bottom of the paint film, etc., and achieve excellent drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

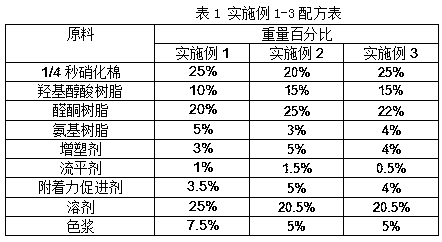

[0012] The present invention will be described in detail below in conjunction with the examples.

[0013]

[0014]

[0015] The above examples adopt the following preparation process: first mix the solvent evenly, slowly add 1 / 4 second of nitrocellulose while stirring with a disperser, wait for 1 / 4 second of nitrocellulose to dissolve completely, then add hydroxyl alkyd resin and aldehyde while stirring Ketone resin, after the hydroxy alkyd resin and aldehyde ketone resin are dissolved, add additives in turn while stirring, and stir evenly.

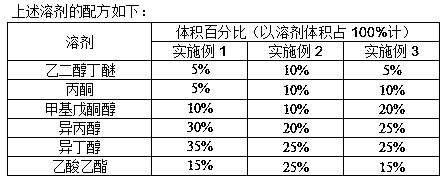

[0016] The varnishes prepared in the above three examples were mixed with the diluent at a volume ratio of 1:3 to obtain a finished topcoat directly used for construction. The formula of the diluent, based on 100% by volume, consists of 20% ethyl acetate, 10% methyl isobutyl ketone, 10% methyl pentanone alcohol, 30% isopropanol, and 30% isobutanol.

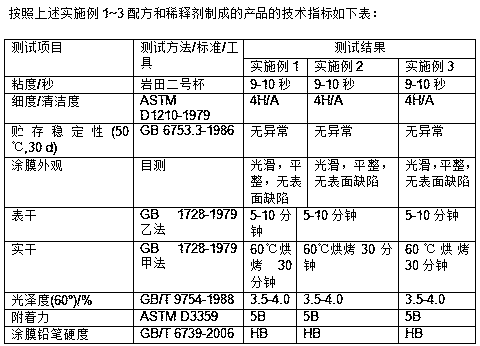

[0017]

[0018] As shown in the table above, the topcoat of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com