Treatment system for homogenization of solid medium formula and method therefor

A processing system and homogenization technology, applied in chemical instruments and methods, liquid ingredient supply devices, mixing plants, etc., can solve the problems of difficult mixing, unfavorable mixing, limited mixing time, etc., and achieve the effect of mixing uniformly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

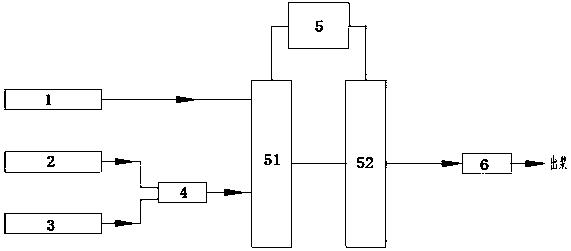

[0037] This embodiment 1 provides a treatment system for homogenizing the fixed formula of nuclear power plant cement, the structural diagram of the treatment system is as follows figure 1 As shown, specifically, the processing system includes a cement metering storage system 1, a water metering system 2, an admixture metering storage system 3, a mixing bin 4, a stirring system 5, and a pumping system 6; the cement metering storage system 1 and the The mixing system 5 is connected, the water metering system 2, the admixture metering storage system 3 and the stirring system 5 are all connected to the mixing chamber 4, and the stirring system 5 is connected to the pumping system 6.

[0038]In this embodiment, each component system realizes the following functions. The cement metering and storage system 1 is used to realize the metering, storage and transportation of specific fixed body formula cement dry material; the water metering system 2 is used to realize specific fixed body...

Embodiment 2

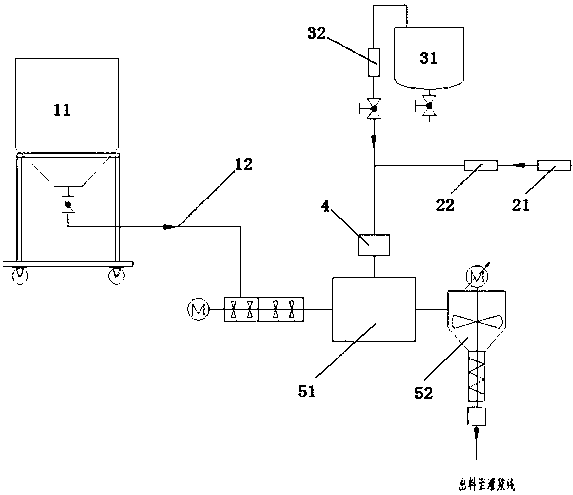

[0046] Based on the same inventive concept, this embodiment provides a method for homogenizing the fixed formula of nuclear power plant cement, which includes a treatment system for homogenizing the fixed formula of nuclear power plant cement described in Example 1, and its process flow is as follows figure 2 As shown, specifically, the method of this embodiment includes the following steps:

[0047] 1) According to the fixed formula requirements of nuclear power plant cement, the dry cement material is transported to the primary mixing bin 51 according to a predetermined amount through the cement metering storage system 1;

[0048] 2) While performing step 1), the liquid components are first transported to the mixing chamber 4 according to the formula requirements, and then enter the primary mixing chamber 51 after preliminary mixing in the mixing chamber 4. The liquid components include additives and water ;

[0049] 3) While performing steps 1)-2), the primary mixing cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com