Intensity finite element computing method for wind generating set lifting tool

A technology of wind power generators and calculation methods, applied in calculation, design optimization/simulation, electrical digital data processing, etc., can solve problems such as large bolt stress, unreasonable, insufficient pre-tightening force, etc., to avoid hoisting safety accidents, The effect of making up for defects and deficiencies and clear strength properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with specific examples.

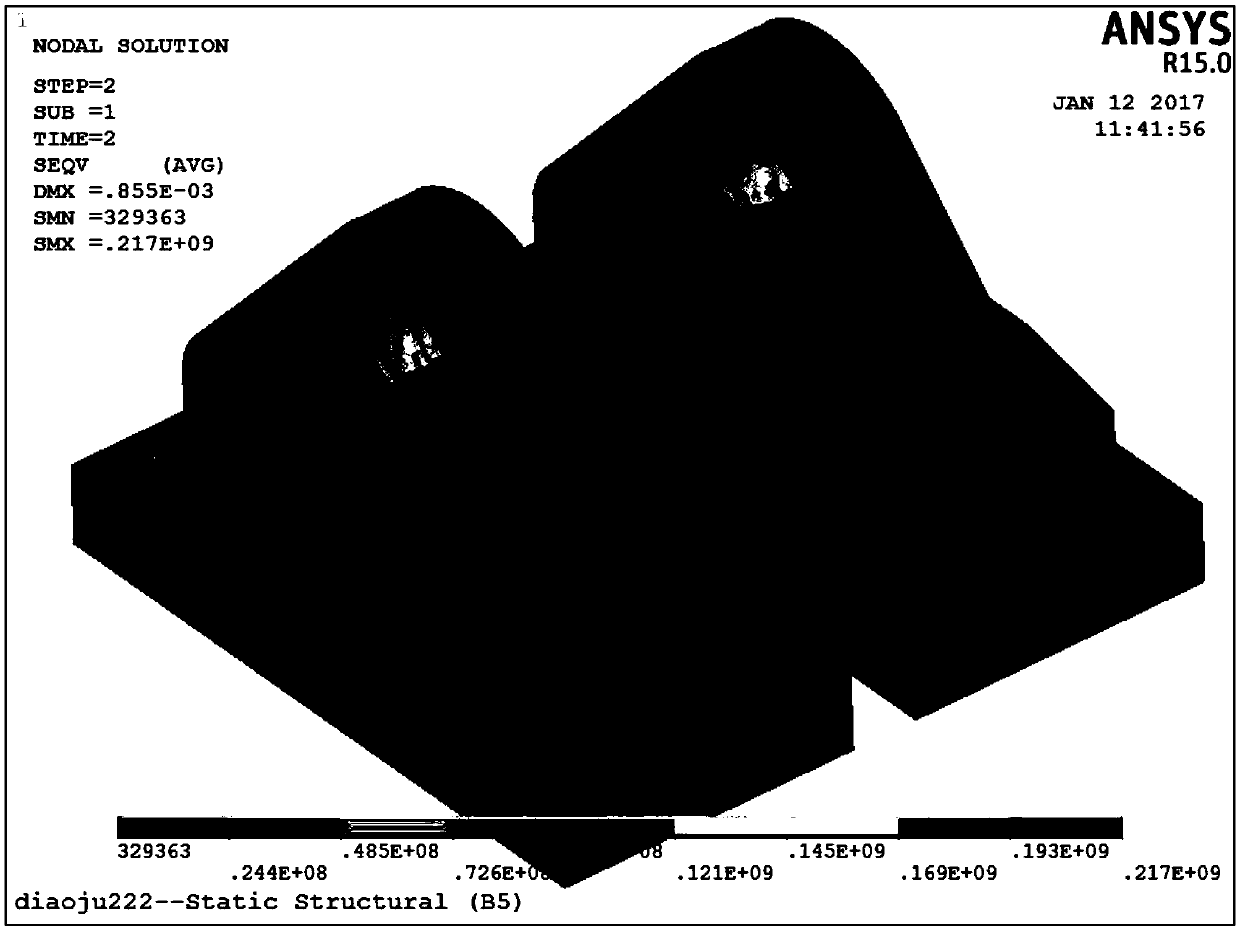

[0045] Taking Mingyang MySE5.5-155 wind power generating set impeller system hoisting hanger strength calculation as an example, the strength finite element calculation method of the present invention is used to check the strength of the hanger and bolts. The specific implementation process is as follows:

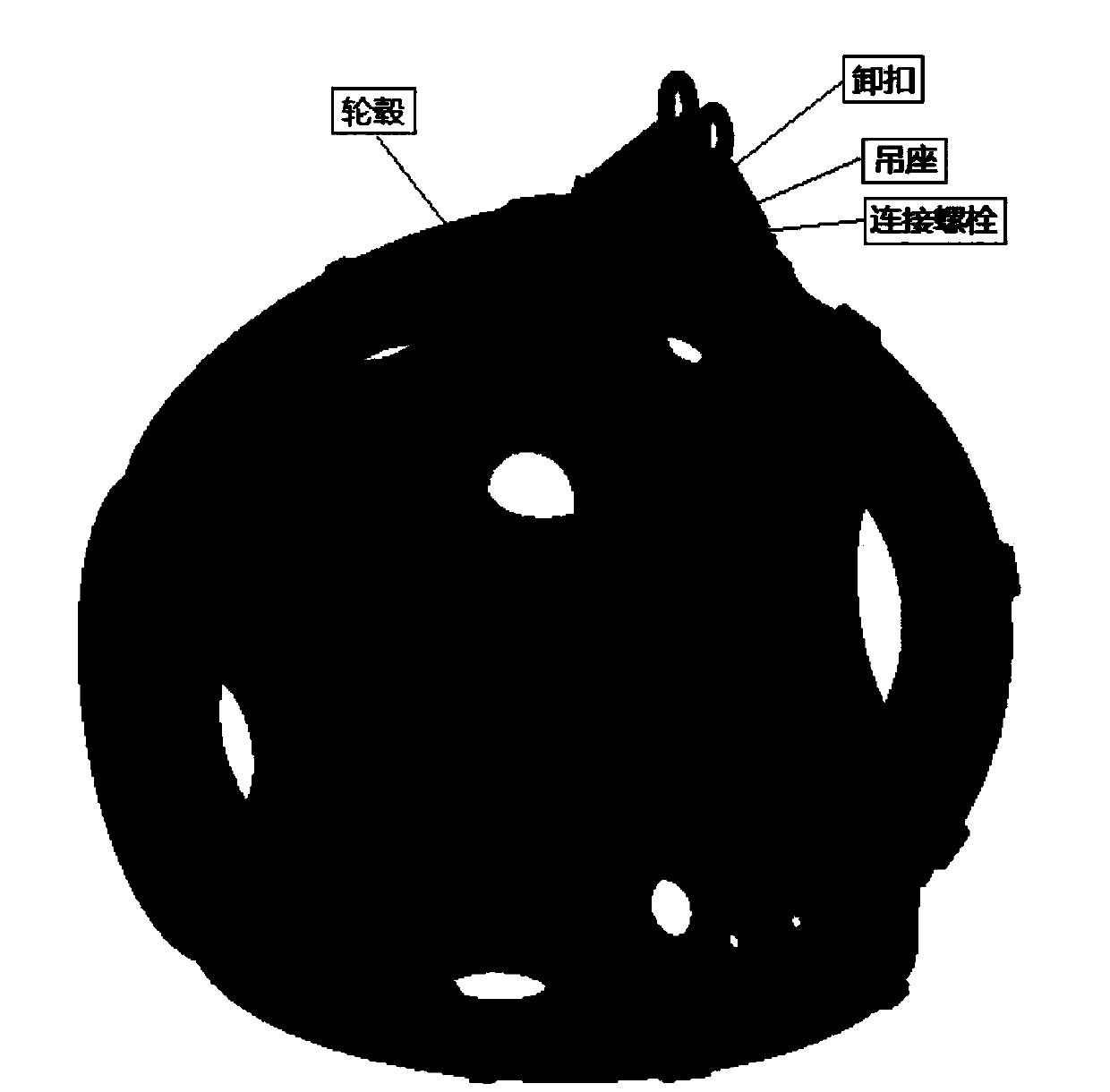

[0046] 1) To establish the actual hoisting 3D solid model in the Solidworks software, only the assembly models of the hanger, bolts and hubs need to be established, such as figure 1 As shown, other auxiliary components can be ignored, but their mass should be considered when loading. The total weight of the impeller system is 200,000kg, and it is hoisted by two hangers and 20 M48 high-strength bolts of grade 10.9.

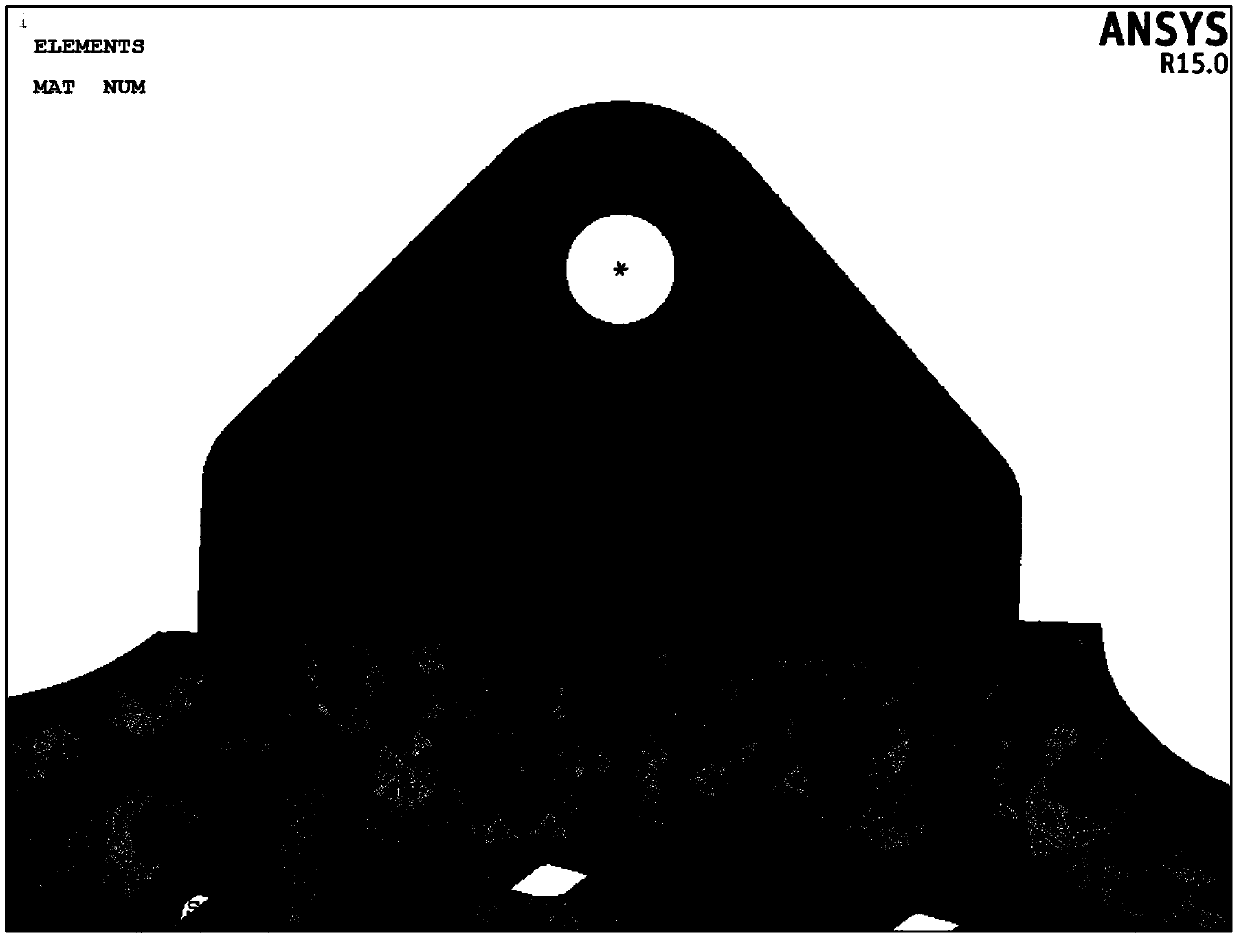

[0047] 2) Import the 3D solid assembly model into the Workbench software to simplify the model, delete unnecessary features and auxiliary parts, such as deletin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com