Air conditioner system

An air-conditioning system and channel technology, applied in lighting and heating equipment, compressors, fluid circulation arrangements, etc., can solve problems such as large flow resistance, reduced efficiency of the main cylinder compression process, and limited space for the air supply aperture of the sliding vane.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

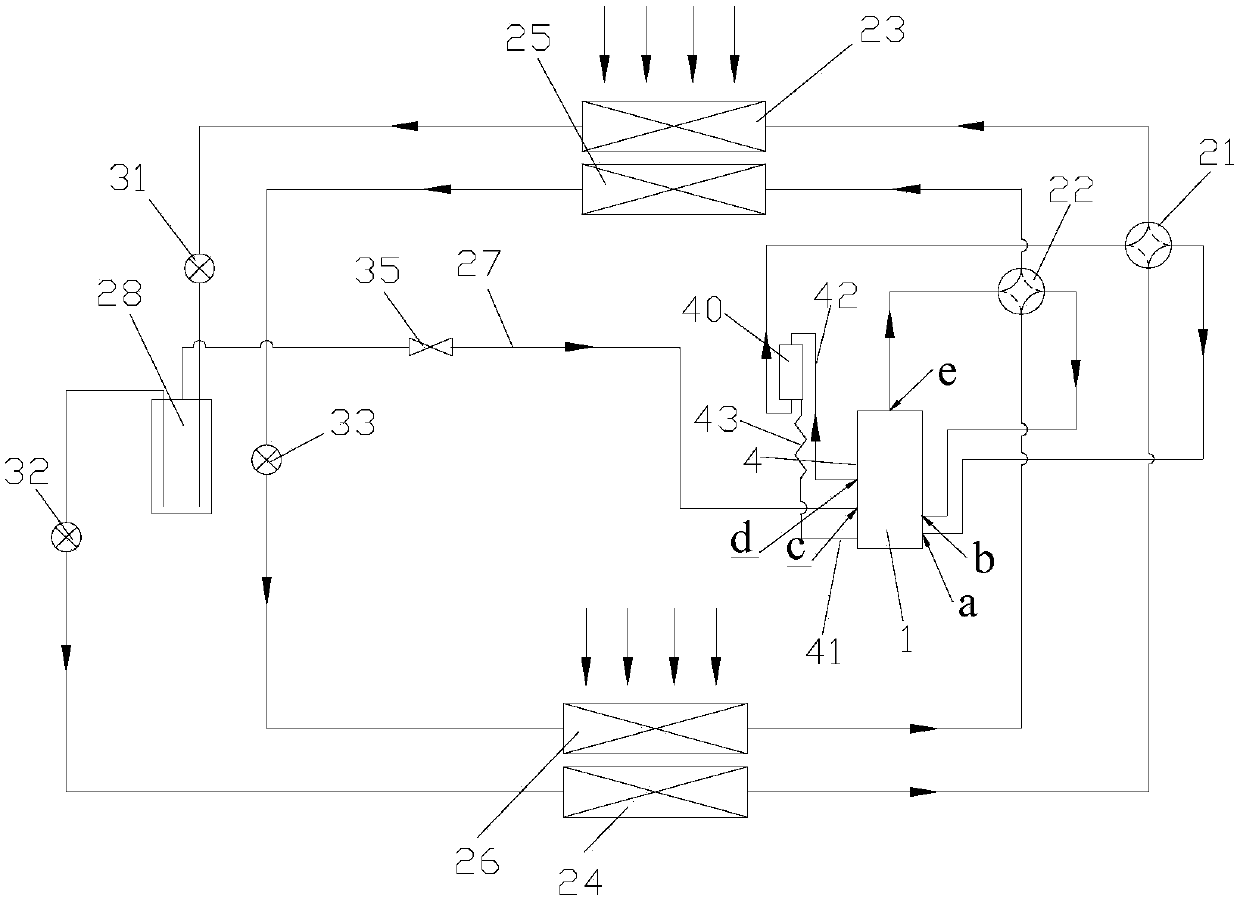

[0035] Figure 5 and Figure 6 as well as Figure 9 to Figure 12 The solid line arrows in indicate that the pipeline is connected, and the dotted line arrows indicate that the pipeline is disconnected.

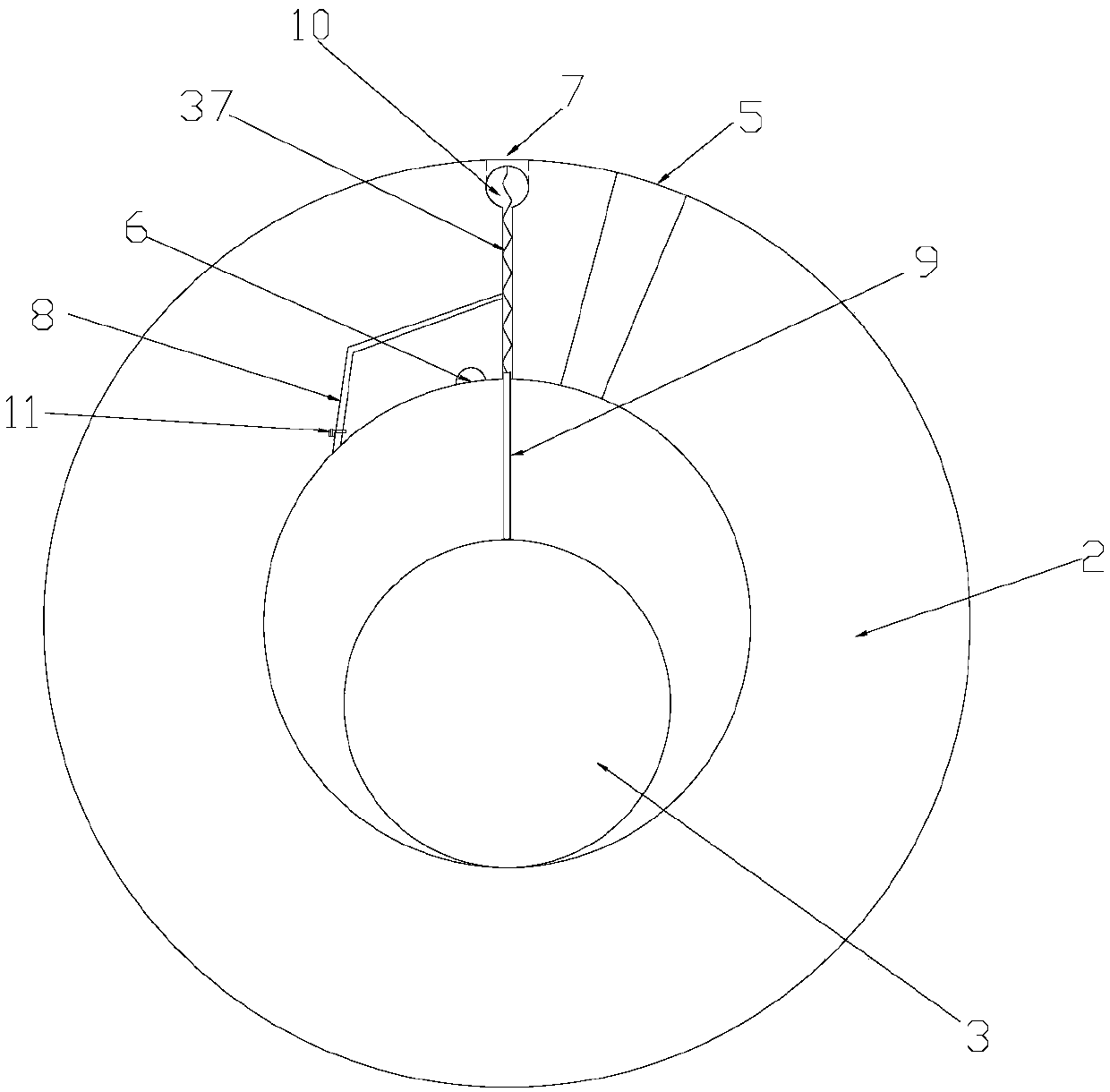

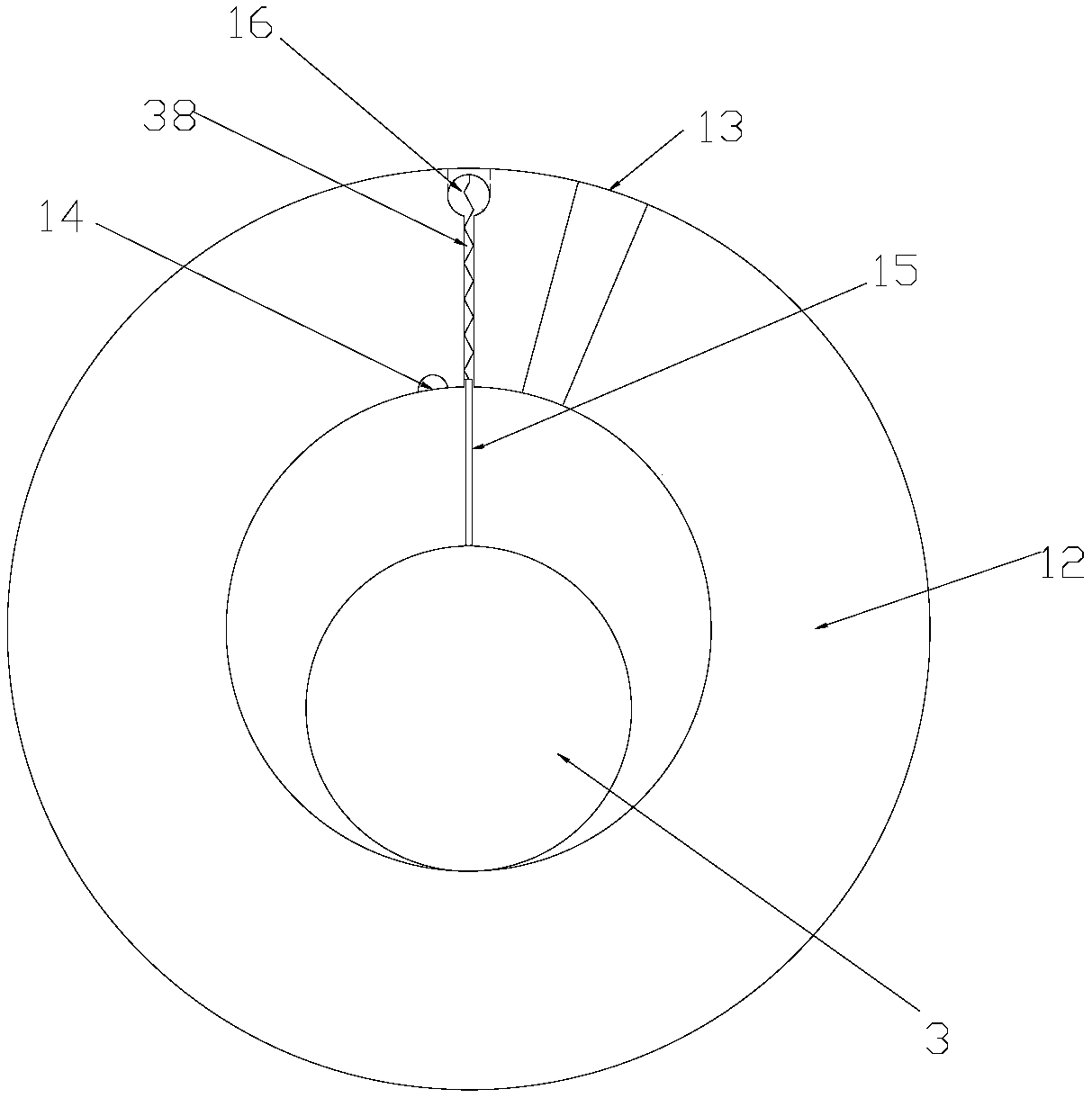

[0036] see in conjunction Figure 1 to Figure 12 As shown, according to the embodiment of the present invention, the air conditioning system includes a compressor 1, the compressor 1 includes a pump body assembly, the pump body assembly includes a first cylinder 2 and a rotor 3, the first cylinder 2 has a compression chamber, and the rotor 3 is eccentrically arranged on In the compression chamber, the cylinder body of the first cylinder 2 is provided with a first air intake inlet 5, a first exhaust outlet 6, a first air supply inlet 7 and a first air supply channel 8, and the first air supply channel 8 can be selected Connected with the first air supply inlet 7, the cylinder is also provided with a first sliding vane 9 and a first sliding vane groove 10, the first sliding v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com