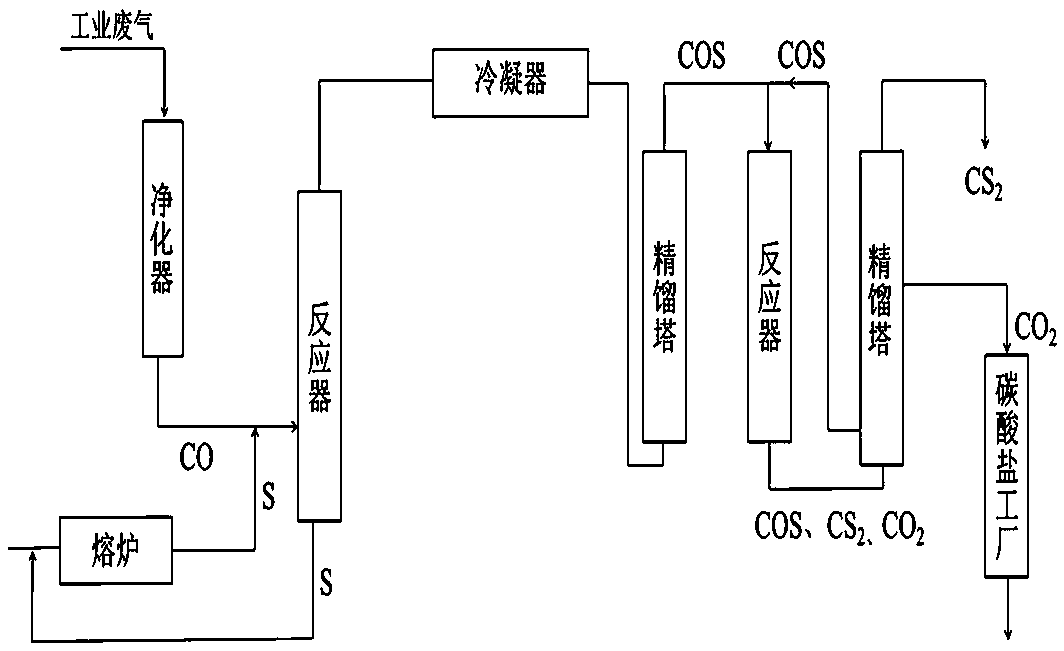

Method for preparing carbon disulfide from industrial tail carbon monoxide as raw material

A technology of carbon monoxide and carbon disulfide, which is applied to the preparation of carbon disulfide, carbon sulfur compounds, carbonates/acid carbonates, etc., can solve the problems of low sulfur conversion rate, low conversion rate, and high temperature required for reaction, and achieve yield The effect of high efficiency, improved utilization rate, and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. A method for preparing carbon disulfide with industrial tail gas carbon monoxide as raw material, the method may further comprise the steps:

[0025] a. Sulfur is quantitatively added to the carbon oxysulfide reactor after melting, and a metal sulfide catalyst is added in the reactor, and the sulfur liquid volume should account for 1 / 3-2 / 3 of the reactor volume, and the best is 1 / 2 or so, and then pass the dehydrated and dried carbon monoxide into the reactor. The carbon monoxide raw material is obtained by purifying the tail gas of the nitrogen fertilizer plant; it is evenly mixed with sulfur steam, and then enters the tubular carbon oxysulfide reactor. Under normal circumstances, carbonyl sulfide is generated at 350-450°C; the amount of carbon monoxide introduced should be 4-6% in molar excess, so that carbon monoxide can be fully utilized. The catalyst is a simple and easy-to-obtain metal sulfide, such as 3%~4% NiS, 9.8%~10% K 2 S, 1.8% α-CoS, supported by Al 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com