Actuating mechanism of mechanical shearing machine

A technology for actuators and shearing machines, which is applied to the attachment of shearing machines, shearing devices, and shearing machine equipment, etc. It can solve the problems that the mounting base is not convenient for fixed installation, and the installation position cannot be adjusted according to actual needs. The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

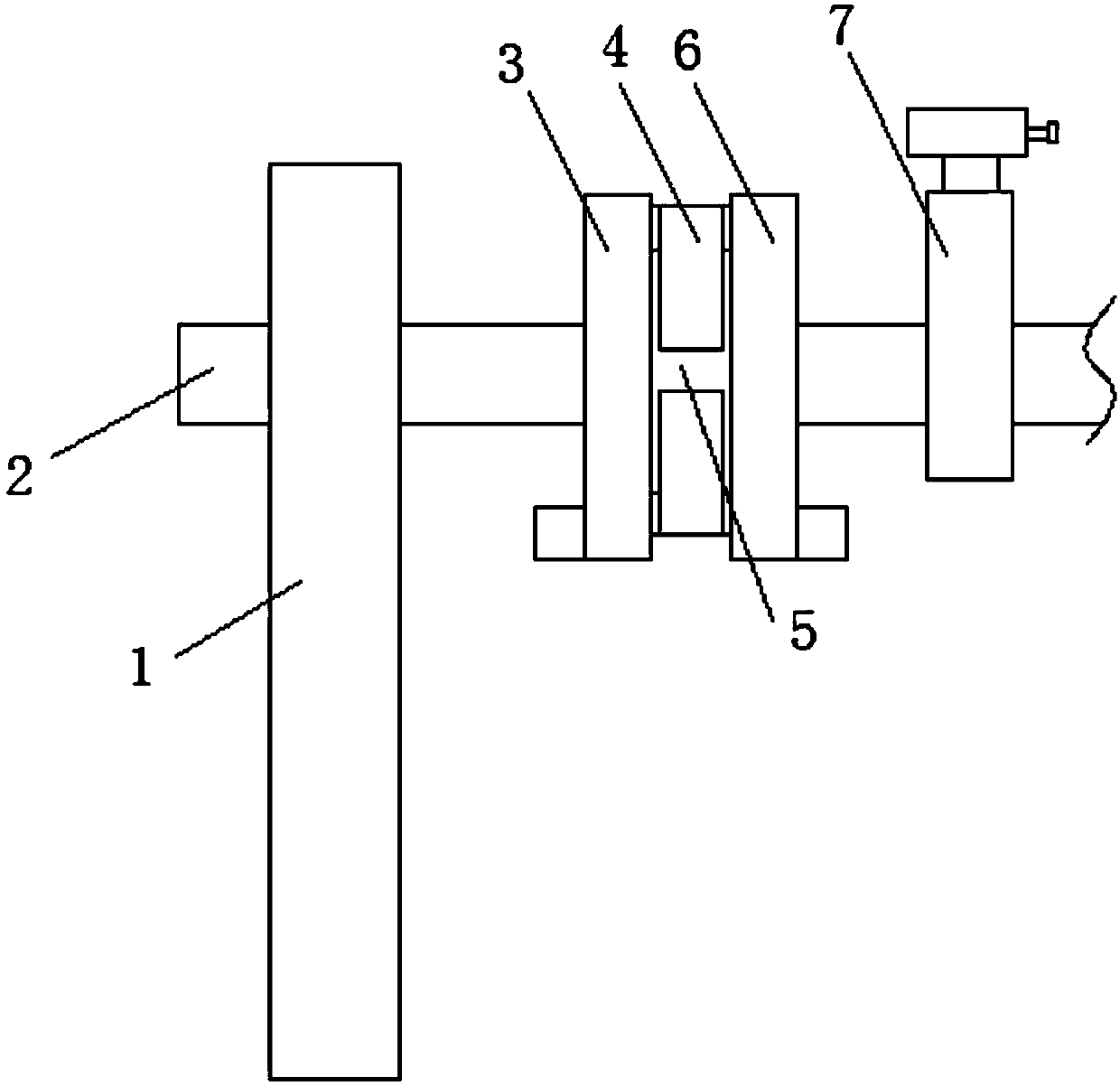

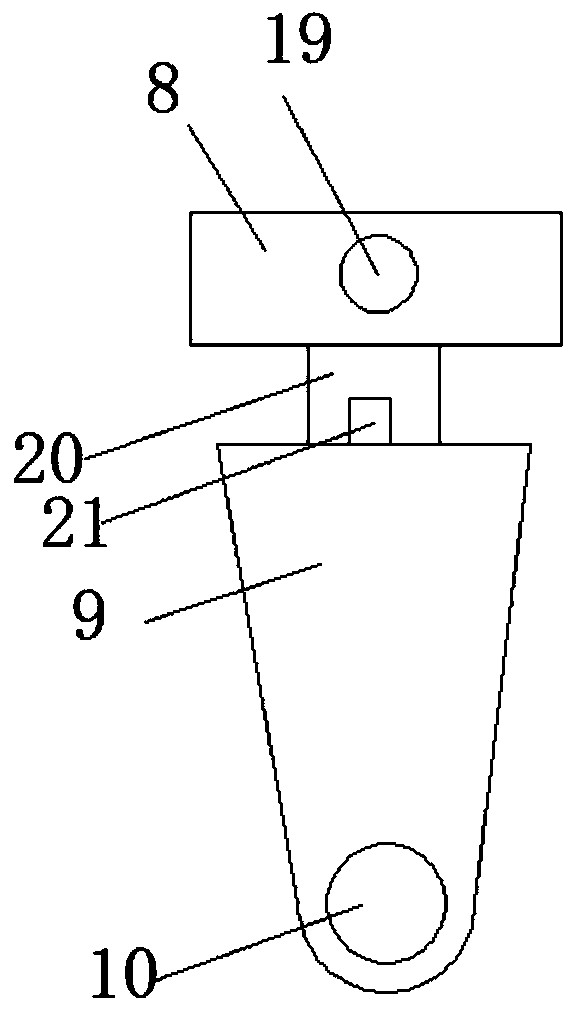

[0029] refer to Figure 1-7, the executive mechanism of the mechanical shearing machine is proposed in this embodiment, including a side bracket 1, a main shaft 2 is mounted on the side bracket 1 for horizontal rotation, the outer key of the main shaft 2 is connected with an eccentric wheel 5, and the outer side of the eccentric wheel 5 is movable The pendulum shell 4 is set, and the side of the pendulum shell 4 close to the side bracket 1 is installed with the left sealing cover 3 fixedly set with the outside of the main shaft 2, and the other side of the pendulum shell 4 is installed with the outside of the main shaft 2. Right sealing cover 6, the side of right sealing cover 6 away from eccentric wheel 5 is provided with adjustable mounting seat 7, and adjustable mounting seat 7 comprises fixed seat 8 and is positioned at the vertical moving seat 9 below fixed seat 8, and moves vertically The seat 9 is provided with a main shaft through hole 10 which is installed in rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com