Preparation method of antibacterial underwear fiber fabric

A fiber and fabric technology, applied in the field of preparation of antibacterial underwear fiber fabrics, can solve the problems of natural antibacterial performance decline, fabric physical performance changes, unfavorable human health, etc., to increase brand loyalty, ensure physical health, and improve market competitiveness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

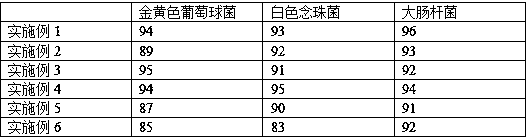

Examples

Embodiment 1

[0016] (1) Weigh 20% of bamboo fiber, 60% of cotton fiber, 10% of polyester fiber and 10% of nano-silver ion fiber according to a certain weight ratio. oC After freezing for 4 hours under the ultra-low temperature condition, carry out mechanical pulverization, put it in a mixer, at 40 o Mix well under C;

[0017] (2) the mixed material obtained in the step (1) is placed in a twin-screw extruder to make a spinning melt;

[0018] (3) Add 2% natural bamboo vinegar liquid and 1% vanilla oil in the spinning melt that obtains in step (2), adopt low-temperature decompression drying technology then, at 40 o C drying it to obtain a modified spinning melt;

[0019] (4) the spinning melt that obtains in the step (3) is at 280 oC Carry out melt spinning, obtain spinning fiber with the speed of 1200 m / min;

[0020] (5) The spun fiber obtained in the step (4) is washed, bleached, oiled, dried, and spun into a fabric to obtain an antibacterial underwear fiber fabric.

Embodiment 2

[0022] (1) Weigh 30% of bamboo fiber, 50% of cotton fiber, 10% of polyester fiber and 10% of nano-silver ion fiber according to a certain weight ratio. o Under the ultra-low temperature condition of C, freeze for 5 hours, carry out mechanical pulverization, place in a blender, at 45 o Mix well under C;

[0023] (2) the mixed material obtained in the step (1) is placed in a twin-screw extruder to make a spinning melt;

[0024] (3) add 3% natural bamboo vinegar liquid and 2% lavender oil in the spinning melt that obtains in step (2), adopt low-temperature decompression drying technology then, at 45 o C drying it to obtain a modified spinning melt;

[0025] (4) the spinning melt that obtains in the step (3) is in 300 o C carries out melt spinning, obtains spinning fiber with the speed of 1100 m / min;

[0026] (5) The spun fiber obtained in the step (4) is washed, bleached, oiled, dried, and spun into a fabric to obtain an antibacterial underwear fiber fabric.

Embodiment 3

[0028] (1) Take 15% of bamboo fiber, 65% of cotton fiber, 15% of polyester fiber, and 5% of nano-silver ion fiber by a certain weight ratio. o Under the ultra-low temperature condition of C, freeze for 6 hours, carry out mechanical pulverization, place in a mixer, at 45 o Mix well under C;

[0029] (2) the mixed material obtained in the step (1) is placed in a twin-screw extruder to make a spinning melt;

[0030] (3) Add 4% natural bamboo vinegar liquid and 1% vanilla oil in the spinning melt obtained in step (2), then adopt low-temperature decompression drying technology, at 50 o C drying it to obtain a modified spinning melt;

[0031] (4) the spinning melt that obtains in the step (3) is in 320 o C carries out melt spinning, obtains spinning fiber with the speed of 1400 m / min;

[0032] (5) The spun fiber obtained in the step (4) is washed, bleached, oiled, dried, and spun into a fabric to obtain an antibacterial underwear fiber fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com