Stacking method of packaging material band and warping-prevention jig used for packaging material band

An anti-warping and packaging material technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems affecting the process, the packaging material tape cannot be pressed, etc., to achieve flat and uniform stress, to avoid warping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to better understand the spirit of the present invention, it will be further described below in conjunction with some preferred embodiments of the present invention.

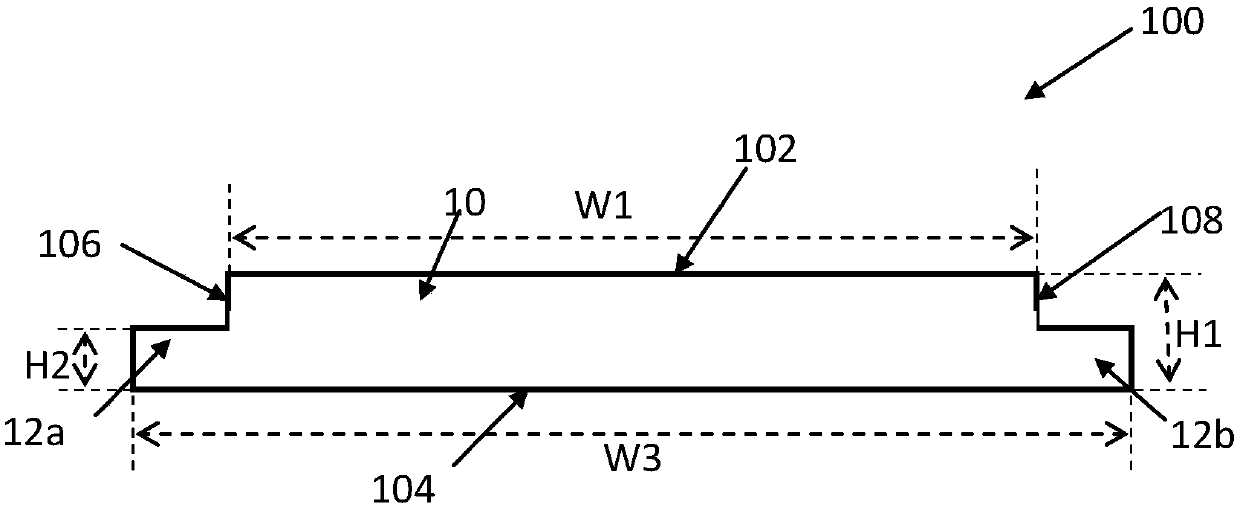

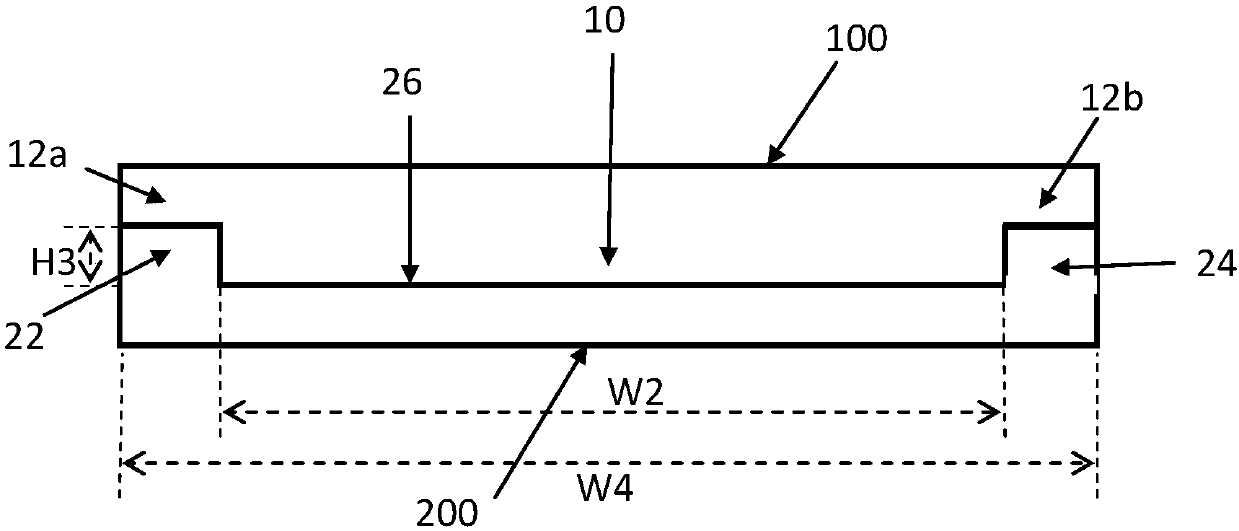

[0014] For MIS-type lead frames or packaging substrates, since the pre-packaging process is adopted, the packaging material strips are surrounded by raised borders. In order to prevent the raised frame from affecting the speed and quality of injection molding, the injection mold will be improved, which leads to the presence of raised frames on both sides of the injection-molded encapsulation strip. Therefore, when performing PMC on these injected packaging material strips, the gaps between the stacked packaging material strips are easy to warp, which affects the subsequent manufacturing process.

[0015] The stacking method of packaging material strips and the anti-warping jig provided by the embodiments of the present invention can effectively solve the above problems.

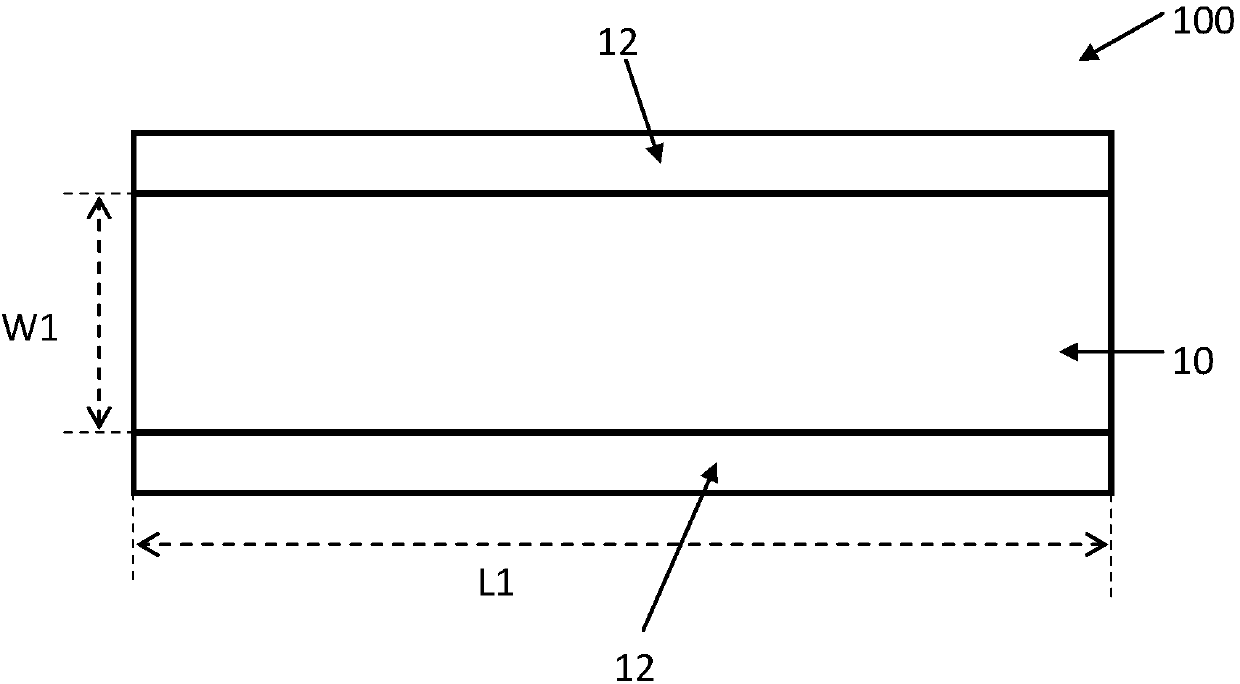

[0016] figure 1 Shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com