Real-time monitoring system and monitoring method for downhole tension of single-core cable for perforation

A real-time monitoring system and single-core cable technology, applied in tension measurement, measurement, earthwork drilling and mining, etc., can solve problems such as the inability to monitor the tension of single-core cables downhole in real time, and achieve easy maintenance, reliable communication, and high system reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

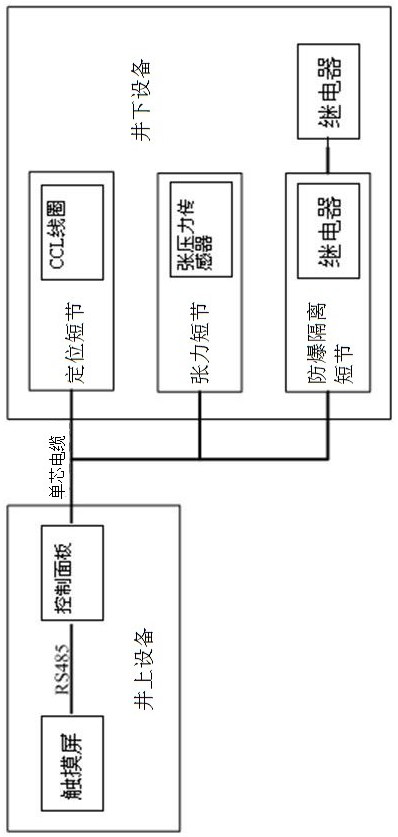

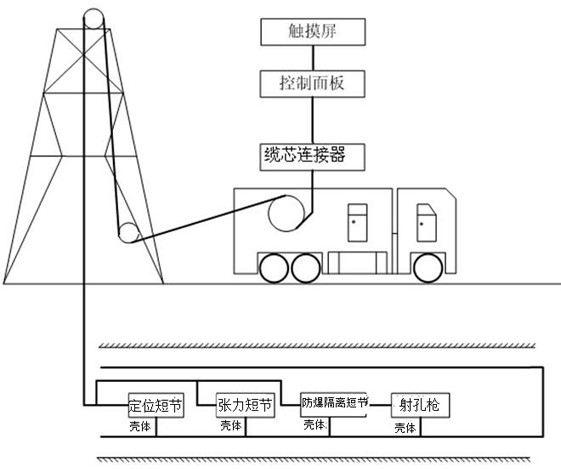

[0043] A single-core cable downhole tension real-time monitoring system for perforation, including uphole equipment and downhole equipment, the uphole part includes a display screen and a control panel, the display screen is connected to the control panel, and the downhole part includes a positioning nipple, a tension nipple and an explosion-proof The downhole instrument string is formed by connecting the isolation subs in sequence, the explosion-proof isolation subs are connected to the perforating guns, the control panel is respectively connected to the positioning subs, the tension subs and the explosion-proof isolation subs through single-core cables, the positioning subs, the tension subs and the The control circuit lines of the explosion-proof isolation pup joints are connected in parallel. Rely on the multi-core integrated socket to connect the single-core cable. When in use, you can input commands through the control panel to control switching to explosion-proof isolati...

Embodiment 2

[0062] This embodiment further illustrates the present invention in conjunction with the accompanying drawings.

[0063] The invention is located at the lower part of the bridle and the upper part of the perforating gun, and is suitable for cable perforation operations. The invention is compatible with the single-core cable depth correction system, and can also obtain the magnetic positioning signal (also called CCL signal) of the casing collar while the single-core cable obtains the tension signal; the invention can be used in the high temperature and high pressure environment underground; The invention can not affect the use of the electronic perforation selection system of oil and gas wells, that is, the communication of another set of single-core cables at the lower end of the pipe string can not be affected, and can not be affected by it; the invention can resist the impact of perforation.

[0064] A single-core cable downhole tension real-time monitoring system for perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com