Plastic-steel door and window assembly plug-in connector

A technology for plastic-steel doors and windows and plug-ins, which is applied in windows/doors, building components, buildings, etc. It can solve the problems of complex structure and poor versatility of assembly parts, and achieve the effects of improving aesthetics, long life, and good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

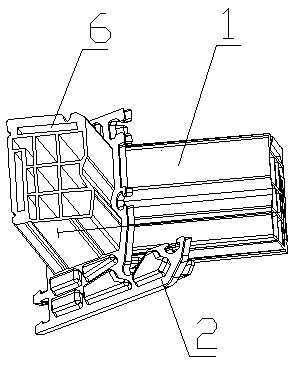

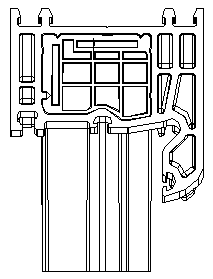

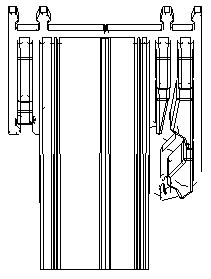

[0032] like Figure 1-15 As shown, the plastic-steel door and window assembly plug-in includes a follow-up main body connector 1, a follow-up waterproof positioning connector 2, a steel reinforcement sheet 3 and screws 4, and the cross-sections at both ends of the follow-up main body connector 1 and the assembly profile The shape of the cross-section is compatible with the interior and is hollow, so as to realize the tight and seamless connection inserted into the profiles on both sides. The said waterproof positioning connectors 2 are two in opposite directions, which are respectively arranged on the connectors 1 of the corresponding main body. The two sides of the middle part are at the same position, and the said follow-up waterproof positioning connector 2 is provided with protrusions matching the internal structures on both sides of the assembled p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com