Glue material for run-flat tire supporting glue, preparation method of glue material and run-flat tire

A technology for run-flat tires and support rubber, which is applied in the field of rubber materials for run-flat tire support rubber, and can solve problems such as sidewall breakage, ground contact, and vehicle inability to drive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

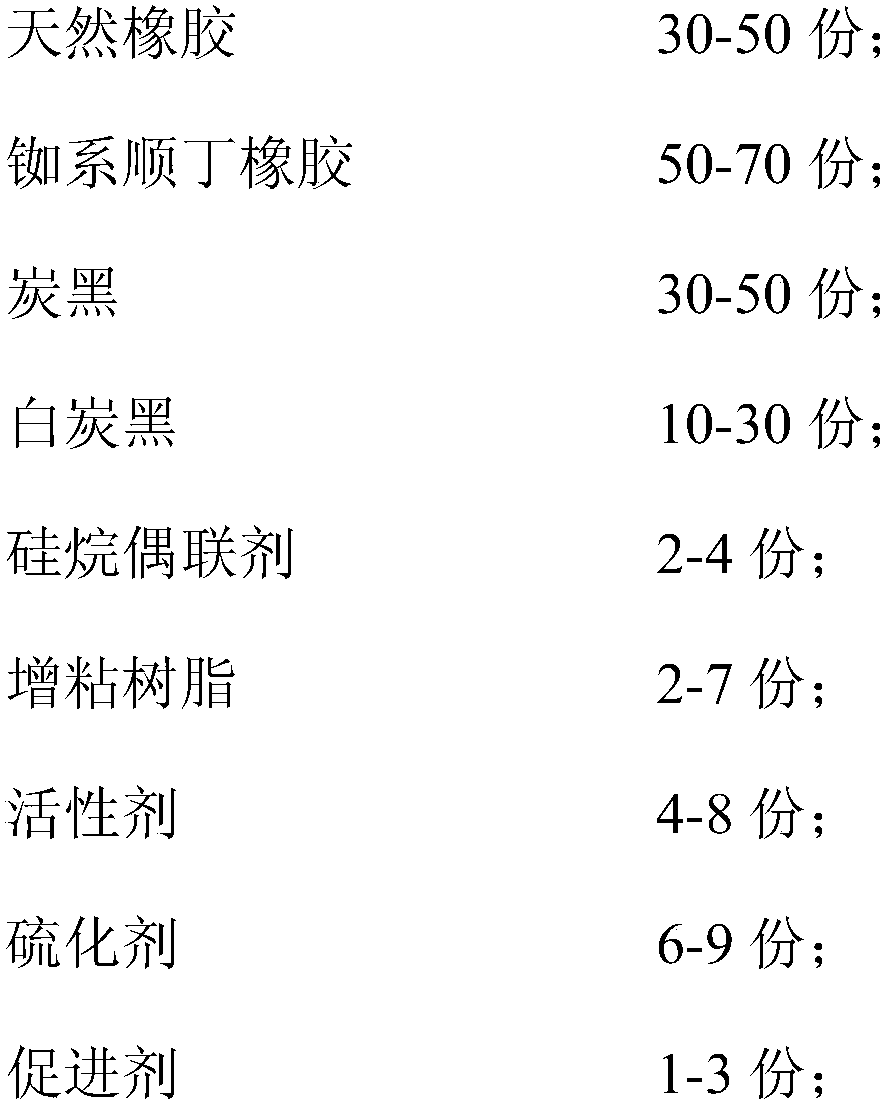

[0072] A rubber material for a run-flat tire support rubber, comprising the following components in parts by weight:

[0073] components

parts by weight

components

parts by weight

30

HMMM

1.5

Rubidium-based butadiene rubber

70

Phenolic Resin

3

Carbon black N660

30

3

Silica

30

1

TESPT

4

insoluble sulfur

6

RF99

1

NS

1

[0074] The preparation method of the above-mentioned run-flat tire support rubber compound is as follows:

[0075] (1) According to the formula, add each component except the vulcanizing agent and accelerator into the internal mixer, mix for 3 minutes, and remove the glue when the temperature reaches 150°C to obtain a mixed rubber;

[0076] (2) After placing the above-mentioned one-stage mixed rubber for 8 hours, mix it in an internal mixer for 2 minutes, and remove the rubber when t...

Embodiment 2

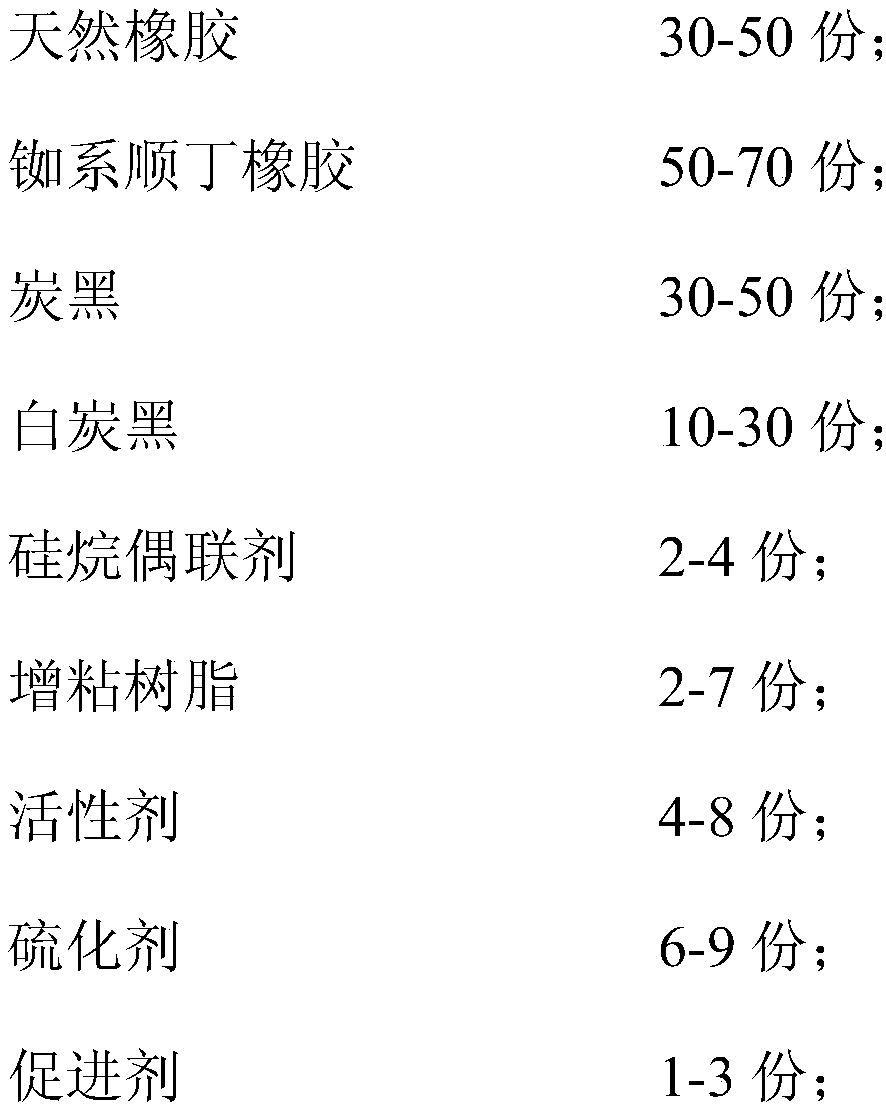

[0079] A rubber material for a run-flat tire support rubber, comprising the following components in parts by weight:

[0080] components

parts by weight

components

parts by weight

50

4

Rubidium-based butadiene rubber

50

1

Carbon black N660

50

insoluble sulfur

9

Silica

10

BYZGR

3

TESPT

2

Antiaging agent RD

1

RF99

1.5

Antiaging agent DMPPD

2

HMMM

2

Anti-reversion agent

0.5

Phenolic Resin

2

[0081] The preparation method of the above-mentioned run-flat tire support rubber compound is as follows:

[0082] (1) According to the formula, add each component except the vulcanizing agent and accelerator into the internal mixer, mix for 3 minutes, and remove the glue when the temperature reaches 150°C to obtain a mixed rubber;

[0083] (2) After placing the above-mentioned...

Embodiment 3

[0086] A rubber material for a run-flat tire support rubber, comprising the following components in parts by weight:

[0087]

[0088]

[0089] The preparation method of the above-mentioned run-flat tire support rubber compound is as follows:

[0090] (1) According to the formula, add each component except the vulcanizing agent and accelerator into the internal mixer, mix for 4 minutes, and remove the glue when the temperature reaches 160°C to obtain a mixed rubber;

[0091] (2) After placing the above-mentioned one-stage mixed rubber for 8 hours, mix it in an internal mixer for 2.3 minutes, and remove the rubber when the temperature reaches 145° C. to obtain the second-stage mixed rubber;

[0092](3) Put the above-mentioned two-stage compounded rubber for 8 hours, mix it together with the vulcanizing agent and accelerator in the internal mixer for 2.5 minutes, and discharge the rubber when the temperature reaches 105°C, and obtain the above-mentioned rubber for run-flat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com